Kuongorora Swiss Type Lathes: Mechanics, Operations, uye Applications

2023-10-23

Swiss Type Lathes, inozivikanwawo seSwiss-style lathes kana Swiss screw machines, ane hunyanzvi uye akakwenenzverwa-engineered machining maturusi anoita basa rakakosha mumaindasitiri akasiyana siyana, anosanganisira aerospace, zvekurapa, uye zvemotokari. Muchinyorwa chino chakadzama, tichapinda mukati menyika yeSwiss Type Lathes, tichiburitsa ma mechanics avo akaomarara uye tichivhenekera mashandiro avanoita. Tichaongororawo mashandisiro avo, zvakanakira, uye tekinoroji inoshanduka.

Chikamu 1: Mavambo eSwiss Type Lathes

1.1. Nhoroondo Midzi

Nhoroondo yeSwiss Type Lathes inogona kuteverwa kumashure kwekutanga 19th century apo nemazvo machine akatanga kuita basa rakakosha muindasitiri yekugadzira wachi yeSwitzerland. Switzerland, inozivikanwa nehunyanzvi hwayo hwekutyisa, yaida nzira yekugadzira zvikamu zvewachi zvakaoma kunzwisisa nehungwaru hukuru. Kuda uku nemazvo machine maturusi akaisa hwaro hweiyo yaizopedzisira yava Swiss Type Lathes. Mukutanga kwezana ramakore rechi 19, machira akajairwa akashandiswa muindasitiri yekugadzira wachi yeSwitzerland. Zvisinei, marashi aya akanga asina kunyatsokodzera zvinodiwa pakugadzira wachi, izvo zvaida kugadzirwa kwezvikamu zviduku, zvakaoma kunzwisisa, uye zvakanyatsojeka. Vagadziri vewachi vakatarisana nedambudziko: vaida nzira yekutenderedza nekugaya zvidimbu zvidiki zvine huchokwadi hunoshamisa. Nguva yebudiriro yakauya nekugadzirwa kwechitsigiro chokunzvenga simbi nemuchina wewachi weSwiss Breguet muna 1795. Ichi chigadzirwa chaida mativi akanyatsojeka, izvo zvakaita kuti kudikanwa kwounyanzvi hwepamusoro hwokugadzira michina. Semhinduro, vagadziri vewachi veSwitzerland vakatanga kuyedza neakasiyana lathe magadzirirwo uye magadzirirwo kuti awane chaiyo inodiwa. Pfungwa yekutsvedza musoro wemusoro, iyo yakabvumira hukuru hwekutonga uye kurongeka mukugadzira madiki maworkpieces, yakatanga kubuda. Vagadziri vewachi veSwitzerland, vakadai saPatek Philippe naLongines, vakaita basa rakakosha mukunatsa aya magadzirirwo ekutanga. Pakasvika pakati pezana ramakore rechi 19, kugadzira wachi dzeSwiss kwakanga kwatove nemukurumbira pasi rose nekuda kwekurongeka kwayo, uye uku kugadziridzwa kwekutanga kwelathes ndiko kwaive pakati pebudiriro iyoyo.1.2. Evolution yeSwiss Lathe Technology

Shanduko yeSwiss Lathe tekinoroji yakaratidzwa nenhevedzano yakakosha yebudiriro tekinoroji iyo yakaramba ichisundidzira miganhu yechaiyo machining. Kufambira mberi uku hakuna kungoumba kusimukira kweSwiss Type Lathes asi kwakapesvedzerawo nzvimbo yakafara yeinjiniya chaiyo. Heano mamwe akakosha ekushanduka kweSwiss Lathe tekinoroji: 1.2.1. Kuberekwa kweTornos Screw Machine (1880s):- Ma1880s akaona kuvandudzwa kweTornos Screw Machine, chiitiko chakakosha mukushanduka kweSwiss Lathe tekinoroji.

- Muchina uyu waive neautomatic threading uye waikwanisa kugadzira zvidimbu zvakaomarara zvine shinda dzinoshamisa.

- Mukutanga kwezana remakore rechi20, kuiswa kwemutungamiri bushing yaive shanduko-mutambo muSwitzerland Lathe tekinoroji.

- Iyo inotungamira bushing, yakamisikidzwa padyo nemidziyo yekucheka, yakapa isingaenzaniswi rutsigiro uye kugadzikana kune yakareba, yakatetepa workpieces, ichigonesa machining chaiwo.

- Ma1970 akaunza kubatanidzwa kweComputer Numerical Control (CNC) tekinoroji muSwiss Type Lathes.

- CNC zvidzoreso zvinotenderwa kuita kwakaringana uye programmable machining mashandiro, zvichiwedzera kuita kwakasiyana-siyana kweaya lathes.

- Kufambira mberi mukushandisa uye tekinoroji yemidziyo yakaita basa rakakosha mukusimudzira mashandiro eSwiss Type Lathes.

- Carbide tooling, kukurumidza-kuchinja maturusi, uye hunyanzvi hwekushandisa geometries zvese zvakabatsira mukuvandudzwa. swiss cnc machine zvigone.

- Mumakumi emakore achangopfuura, kutungamira bushingless Swiss Type Lathes yakawana mukurumbira.

- Michina iyi, ine marara ayo akaderedzwa uye kuwedzera kuita kwakasiyana-siyana, inomiririra kusvetuka kwakakosha muSwiss Lathe tekinoroji.

- Iko kugona kuwana yakanyanyisa kumhanya kwespindle kwave chiratidzo chemazuva ano Swiss Type Lathes.

- High-speed machining inobvumira kukurumidza kugadzirwa uye yepamusoro yepamusoro pekupedzisira.

Chikamu 2: Mechanics yeSwiss Type Lathes

2.1. Zvimiro Zvikamu

Swiss Type Lathes inozivikanwa nekuoma kwayo asi ine hunyanzvi hwekugadzira michina. Ngatitorei zvakadzama kutarisa kukuru kwezvimiro zvikamu uye mabasa avo mu machine kwacho: 2.1.1. Headstock:- Musoro wemusoro chinhu chakakosha chiri kumberi kweSwiss Type Lathe.

- Chinangwa: Iyo inogara iyo huru spindle, iyo inotenderera workpiece. Iyo spindle inofambiswa nemota yelathe uye inopa mafambiro anotenderera anodiwa pakugadzira.

- Basa: Musoro wemusoro unogonesa kurongeka kwepamusoro, kutarisisa, uye kusimba, izvo zvakakosha pakurongeka machining.

- Iyo inotungamira bushing ichubhu-yakafanana chikamu chinotenderedza chinotenderera workpiece.

- Chinangwa: Inopa rutsigiro uye kugadzikana kune iyo workpiece, kuderedza vibrations uye kugonesa chaiyo machining.

- Basa: Iyo inotungamira bushing inobata iyo workpiece yakasimba panzvimbo ichibvumira chete hurefu hunodiwa kuti uwedzere kupfuura iyo, kuderedza flex uye kuve nechokwadi chekugadzira machining.

- Iyo huru yemudziyo inobata inomisikidzwa padyo negwara bushing.

- Chinangwa: Inobata chishandiso chekutanga chekucheka chinoshandiswa kugadzira iyo workpiece.

- Basa: Iyo huru yekushandisa inobata inopa yakagadzikana chikuva chekucheka chishandiso, kuve nechokwadi chechokwadi mukucheka mashandiro.

- Mamwe maSwiss Type Lathes akashongedzerwa ne-sub-spindle iri kuseri kwemuchina.

- Chinangwa: Iyo sub-spindle inoshanda seyechipiri spindle inogona kubata uye muchina iyo workpiece kubva kune yakatarisana kumagumo.

- Basa: Inogonesa kupedzwa kwezvikamu zvakaoma nekubvumira machining pamigumo yese yebasa rekushanda mune imwechete setup.

- Swiss Type Lathes inogona kusanganisira mhenyu maturusi akabata, anowanzo kuwanikwa pamuchina gang slide kana turret.

- Chinangwa: Vabatiri vezvishandiso mhenyu vanobvumira mashandiro echipiri machining, sekuchera uye kugaya, kuti aitwe pane workpiece pasina kuibvisa pamushini.

- Basa: Aya maturusi anobatisa anowedzera kuwanda kwelathe uye kuderedza kudiwa kwekuwedzera machining setups.

- Musoro unotsvedza igungano rinofambiswa rinogona kutsvedza pamubhedha welathe.

- Chinangwa: Basa rayo rekutanga ndere kugonesa chaiyo uye yakawiriraniswa machining eakareba, akatetepa workpiece.

- Iyo inotsvedza musoro wepamusoro inogonesa yakasarudzika nekubvumira iyo workpiece kuti itsigirwe padhuze nekucheka chishandiso.

- Basa: Kuva pedyo uku kunoderedza kutsauka, kutenheka, uye kukanganisa, zvichikonzera kurongeka kwechikamu chepamusoro uye kupera kwepamusoro.

- Marefu uye akatetepa maworkpiece, anowanzo kunetsa kumashini pane akajairwa lathes, anogadzirwa zvakanaka uchishandisa inotsvedza musoro.

- Basa: Iyo inotsvedza yemusoro inofambisa inoenderera mberi machining pasina kudikanwa kwekugara uchimisikidzwa, kuderedza nguva yekutenderera uye kuve nechokwadi chechikamu kuenderana.

- Swiss Type Lathes inoshandisa akasiyana marudzi ezvishandiso, kusanganisira static uye mhenyu zvibatiso zvekushandisa.

- Kukosha: Vabati vemidziyo vanochengetedza maturusi ekucheka munzvimbo uye simbisa kurongeka kwavo kwakaringana neworkpiece.

- Kurongeka: Kuomarara uye kugadzikana kwevashandisi kwakakosha kuti uwane kuchekwa chaiko uye kuchengetedza chikamu kushivirira.

- Turusi geometry, senge rake angles uye clearance angles, inofanirwa kusarudzwa zvichibva pane chaiyo machining zvinodiwa.

- Kukosha: Yekushandisa chaiyo geometry inoderedza masimba ekucheka, inoderedza kupfeka kwezvishandiso, uye inosimudzira kupera kwepamusoro.

- Kusarudzwa Kwezvinhu: Chishandiso chemidziyo, senge carbide kana simbi inomhanya kwazvo, inokanganisa hupenyu hwematurusi uye kucheka mashandiro, zvichiita kuti ive yakakosha kufunga.

Chikamu 3: Mashandiro eSwiss Type Lathes Anoshanda

3.1. Material Kudyisa Mechanism

Iyo nzira yekudyisa zvinhu muSwiss Type Lathes chinhu chakakosha chinobvumira marefu, akatetepa workpiece kuti anyatso kurodzwa uye kugadzirwa. Heino mashandiro azvinoita: Material Loading:- Mabhawa akareba, akatwasuka emidziyo, anowanzo gadzirwa nesimbi sesimbi isina tsvina kana aluminium, anoiswa mulathe's bar feeder.

- Iyo bar feeder inobata uye inosimudzira zvinhu mumushini.

- Sezvo zvinhu zvinopinda mumushini, zvinopfuura negwara rinotungamira, iro rakamisikidzwa pedyo zvakanyanya nemidziyo yekucheka.

- Iyo inotungamira bushing inopa rubatsiro rwakakosha uye kutungamira kune izvo zvinhu, kuve nechokwadi kuti inoramba yakagadzikana uye yakatarisana panguva yekugadzira.

- Izvo zvinhu zvinofambiswa mberi kuburikidza negwara bushing sezvo machining process inofambira mberi, ichibvumira kune chaiyo uye inoenderera machining.

- Iyo inotungamira bushing inoderedza kuzunguzika uye kutsauka kwezvinhu, izvo zvinonyanya kukosha kana uchigadzira marefu uye akatetepa workpiece.

- Iyo inobatsira kune yakasarudzika chaiyo iyo Swiss Type Lathes inozivikanwa nayo.

3.2. Precision Machining

Precision machining paSwiss Type Lathe inosanganisira nhevedzano yakanyatsorongeka matanho ane chinangwa chekuwana kurongeka kwakasarudzika uye kupera kwepamusoro: Nhanho 1: Kugadzirira kwezvinhu.- Iyo mbishi inoiswa mubhawa feeder, uye kureba kwayo kunogadziriswa kuti ive nechokwadi chekuti inongopfuura kupfuura gwara rekutungamira.

- Iyo workpiece inotenderedzwa neiyo huru yekuruka apo maturusi ekucheka, akaiswa pane maturusi, anobatana nezvinhu.

- Kucheka mashandiro anogona kusanganisira kutenderedza, kupinza, grooving, kuchera, uye kugaya, zvichienderana nemagadzirirwo echikamu uye zvakatemwa.

- Kumhanya kwepamusoro-soro chiratidzo cheSwiss Type Lathes. Ivo vanobvumira kukurumidza kubviswa kwezvinhu mitengo uye yepamusoro yepamusoro pekupedzisira.

- Iko kusanganiswa kwekumhanya kukuru kwespindle uye gidhi bushing tsigiro inodzikisira kucheka masimba uye kudedera, ichiwedzera kurongeka.

- Swiss Type Lathes inowanzo ratidza nekukurumidza maturusi ekuchinja masisitimu, ayo anobvumira kukurumidza kushandura maturusi panguva yekugadzira.

- Kurumidza kushanduka kwechishandiso kunoderedza nguva yekudzikira uye kuwedzera kugadzirwa, zvichiita kuti mashandiro akasiyana aitwe mune imwe chete set.

- Swiss Type Lathes inokunda pakuita akawanda machining mashandiro panguva imwe chete.

- Nepo iyo huru spindle ichishanda kune imwe mugumo weworkpiece, mhenyu vabati vezvishandiso vanogona kuita zvechipiri mashandiro, sekuchera kana kugaya, kune rimwe divi.

- Mamwe maSwiss Type Lathes ane sub-spindle, inobvumira machining pamigumo yese yeworkpiece mune imwechete setup.

- Kugona uku kunonyanya kubatsira kune zvikamu zvakaoma zvinoda machining kumativi ese ari maviri.

3.3. Swiss Lathe Programming

Swiss Lathe programming inosanganisira kushandiswa kweComputer Numerical Control (CNC) masisitimu kudzora mafambiro nemashandiro elathe. Heano akakosha maficha eSwitzerland Lathe programming: CNC Controls:- Swiss Type Lathes yakashongedzerwa neakaomesesa CNC zvidzoreso izvo zvinobvumira vashandisi kuronga uye kutonga machining maitiro.

- CNC zvidzoreso zvinopa mushandisi-ane hushamwari interface yekuisa chikamu matsanangudzo uye maturusi nzira.

- Iyo programming process inowanzo sanganisira kugadzira G-code, ari alphanumeric mirairo inoraira mafambiro echokushandisa uye cnc machining mashandiro.

- G-makodhi anogadzirwa zvichibva pane dhizaini yechikamu uye inodiwa machining mashandiro.

- Kutendeuka: G00 (kukurumidza kumira), G01 (kududzirwa kwemutsara), G02/G03 (kududzirwa kwedenderedzwa).

- Threading: G76 (threading cycle).

- Kuchera: G81 (kutenderera kutenderera).

- Kugaya: G12/G13 (denderedzwa pocket milling).

- C-axis positioning: G01 ine C-axis kufamba.

- Kugadzira chaiko kusati kwatanga, vashandisi vanowanzo mhanyisa masimulation kuti vaone chokwadi chechirongwa uye kuona kuti nzira dzematurusi hadzina kudhumhana.

3.4. Kutonhodza uye Chip Management

Kutonhodza uye chip manejimendi akakosha maficha eSwiss Type Lathe oparesheni: Inotonhorera Systems:- Swiss Type Lathes ine inotonhorera masisitimu inoendesa mvura yekucheka kunzvimbo yekucheka.

- Kukosha: Inotonhodza inoshandisa zvinangwa zvakawanda, zvinosanganisira kupisa kupisa, kuzora chishandiso, uye kubvisa machipisi.

- Kutonhora kwakakodzera kunobatsira kuchengetedza chishandiso uye tembiricha yebasa, kudzivirira kupisa uye kupfeka kwemidziyo.

- Sezvo maturusi ekucheka achibvisa zvinhu, machipisi anogadzirwa uye anoda kunyatsogadziriswa.

- Chip conveyor kana chip augers anounganidza uye kubvisa machipisi kubva munzvimbo yekugadzira.

- Kushanda chip manejimendi kwakakosha pakusavhiringidza machining uye kuchengetedza nzvimbo yebasa yakachena.

Chikamu 4: Zvikumbiro uye Maindasitiri

Swiss Type Lathes yakawana mashandisirwo akapararira mumaindasitiri akasiyana nekuda kwekusaenzana kwavo nemazvo uye kugona kwavo. Ngationgororei mabasa avo akakosha mukugadzira aerospace, kugadzirwa kwemidziyo yekurapa, chikamu chemotokari, uye zvemagetsi uye microtechnology.4.1. Kugadzira Aerospace

Indasitiri yezvemuchadenga inoda zvinhu zvine hunyanzvi hwepamusoro uye kuvimbika. Swiss Type Lathes yakakosha pakugadzira zvakakosha zvemuchadenga zvakaita sema turbine blades, fasteners, nezvimwe. Turbine Blades:- Swiss Type Lathes inoshandiswa kugadzira turbine blades ine yakaoma airfoil profiles.

- Aya mablades akakosha kune ndege uye magetsi ekugadzira turbines, uko kurongeka kwakakosha pakuita kwakaringana uye kushanda nesimba.

- Swiss lathes inovimbisa kushivirira kwakasimba uye kupedzwa kwepamusoro kwepamusoro, kunowedzera kuita kweturbine.

- Aerospace fasteners, zvinosanganisira mabhaudhi uye screws, inoda chaiyo machining kuve yakachengeteka uye yakavimbika kubatana.

- Swiss Type Lathes inokunda pakugadzira zvinhu izvi nekuenderana uye nemazvo.

- Iko kumhanya uye kurongeka kweaya lathes kunobatsira mukugadzirwa kwakanaka mukugadzira aerospace fastener.

4.2. Medical Device Production

Swiss Type Lathes inoita basa rakakosha muindasitiri yezvokurapa nekugadzira maimplants, zviridzwa zvekuvhiya, zvinhu zvemazino, nezvimwe. Maimplants:- Kudyara kwemapfupa nemazino, senge chiuno prostheses uye mazino screws, zvinoda kunyatsojeka uye biocompatibility.

- MaSwiss Type Lathes anoshandiswa kugadzira zvinhu izvi kubva kuzvinhu zvakaita setitanium uye simbi isina tsvina kusvika kune zvakatemwa.

- Iko kurongeka kweaya lathes kunovimbisa kukwana kwakakwana uye kwekugara kwenguva refu mukuita kwekurapa.

- Zvishandiso zvekuvhiya, zvinosanganisira scalpels neforceps, zvinofanirwa kugadzirwa zvakanaka kuti zvinyatso uye nyore kushandisa.

- Swiss Type Lathes inoshandiswa kugadzira zviridzwa izvi nemazvo uye kuenderana.

- Hunhu uye kuvimbika kwemidziyo yekuvhiya yakagadzirwa neSwitzerland lathes yakakosha mundima yekurapa.

4.3. Automotive Sector

Indasitiri yemotokari inovimba neSwitzerland Type Lathes yekugadzirwa kwezvinhu zvakakosha, kusanganisira majekiseni emafuta, mugodhis, uye zvabatanidza. Mafuta Majekiseni:- Majekiseni emafuta akakosha emota zvinhu zvinoda kurongeka kwepamusoro kuendesa mafuta.

- Swiss Type Lathes inoshandiswa muchina majekiseni zvikamu, kuve nechokwadi chekushivirira kwakaringana kuita kweinjini uye kutonga kwekuburitsa.

- Precision shafts inoshandiswa mumhando dzakasiyana dzemotokari masisitimu, kusanganisira kutapurirana uye drivetrains.

- Swiss Type Lathes inoshandiswa kugadzira aya shafts nekurongeka uye kupera kwepamusoro kunodiwa kuti ushande zvakanaka.

- Zvibatanidza zvemotokari, sezviya zvinoshandiswa mumasisitimu emagetsi, zvinoda machining chaiwo ekubatana kwakavimbika.

- Swiss Type Lathes inoshandiswa kugadzira zvibatanidza zvine madhizaini akaomarara uye kushivirira kwakasimba.

- Indasitiri yemotokari iri kuita shanduko dzakakura, kusanganisira kuchinjika kuenda kumotokari dzemagetsi uye dzinozvimiririra.

- Swiss Type Lathes iri kuchinjika kuti isangane nezvinoda kubuda, senge machining ezvikamu zvemagetsi powertrains uye advanced sensor system.

4.4. Electronics uye Microtechnology

Iwo emagetsi uye microtechnology zvikamu zvinobatsira kubva kuSwitzerland Type Lathes, kunyanya mukugadzirwa kweakaomesesa emagetsi ekubatanidza uye mamicrocomponents. Electronic Connectors:- Swiss Type Lathes inokunda pakugadzira maminiature ekubatanidza anoshandiswa mumagetsi uye kufonera.

- Izvi zvinobatanidza zvinoda pini chaiyo uye socket components, izvo zvinogadzirwa zvakanaka uchishandisa Swiss lathes.

- Swiss Type Lathes yakakosha pakugadzira mamicrocomponents senge giyas, nozzles, uye diki screws anoshandiswa mune akasiyana microtechnology application.

- Sezvo maitiro ekuita miniaturization achienderera mberi, maSwiss lathes anoita basa rakakosha mukuzadzisa zvidikanwi zvezvikamu zvidiki, zvakanyatsojeka.

- Iko kudiwa kwezvidiki uye zvakanyanya compact zvigadzirwa zvemagetsi zvinoramba zvichikura.

- MaSwiss Type Lathes akanyatsokodzera kuburitsa zvidiki, zvemhando yepamusoro-chaizvo zvinhu zvinodikanwa kune smartphones, zvinopfekeka, uye humwe hunyanzvi hunyanzvi.

Chikamu 5: Zvakanakira uye Zvisingakwanisi

Swiss Type Lathes inopa huwandu hwezvakanakira izvo zvinoita kuti zvive zvakakosha mumaindasitiri mazhinji. Nekudaro, ivo vanouyawo nemimwe ganhuriro nezvinetso zvinoda kutariswa. Ngationgororei zvese zviri zviviri zvakadzama:5.1. Zvakanakira zveSwiss Type Lathes

5.1.1. High Precision:

Swiss Type Lathes inozivikanwa nekusarudzika kwayo uye kurongeka. Zvakanakira: Kushivirira kwakasimba kunogona kuwanikwa nguva dzose, zvichiita kuti zvive zvakanakira maindasitiri senge aerospace uye kugadzira michina yekurapa. Zvikamu zvinogadzirwa neSwitzerland lathes zvinoda kushoma post-machining kana kuwedzera kupedzisa mashandiro.5.1.2. Yakaderedzwa Nguva Yekutenderera:

Aya ma lathe akagadzirirwa kukurumidza-kumhanya machining, zvichikonzera nguva pfupi yekutenderera. Zvakanakira: Kuwedzera kugadzirwa uye nekukurumidza kutendeuka nguva mumaindasitiri uko kushanda nesimba kwakakosha, senge mota nemagetsi.5.1.3. Yakasarudzika Surface Inopedza:

Swiss Type Lathes inogadzira zvikamu zvine yepamusoro pepamusoro pekupedzisira nekuda kwekumhanya kwazvo kwespindle uye nemazvo. Zvakanakira: Zvikamu zvine zvakanakisa kupera kwepamusoro zvakakosha mumashandisirwo akaita semidziyo yekurapa nemagetsi, uko aesthetics nekuita kwakakosha.5.1.4. Panguva Imwe Chete:

Swiss lathes inogona kuita akawanda machining mashandiro panguva imwe chete, kuderedza nguva yekuseta. Zvakanakira: Kuwedzera kushanda nesimba uye kudhura-kushanda, kunyanya mumaindasitiri akaita seaerospace nemotokari, uko zvikamu zvakaoma zvinoda mashandiro akasiyana.5.1.5. Marefu uye Mutete Workpieces:

Aya lathes akasarudzika akakodzera kugadzira marefu uye akatetepa workpiece. Zvakanakira: Yakanakira maindasitiri senge aerospace, uko zvinhu zvakaita seturbine blades zvinoda kunyatsoita uye kugadzikana panguva yekugadzira.5.1.6. Kusiyana-siyana:

Swiss Type Lathes inogona kubata zvakasiyana-siyana zvezvinhu, kubva kusimbi kusvika kumapurasitiki. Zvakanakira: Kushanda zvakasiyana-siyana mukusarudza zvinhu kwakakosha mumaindasitiri akaita sekugadzira michina yekurapa nemagetsi, ayo anowanzoda zvehunyanzvi.5.1.7. Efficient Chip Management:

Swiss lathes yakashongedzerwa neanoshanda chip manejimendi masisitimu. Zvakanakira: Kusavhiringidzwa machining uye kuderedzwa nguva yekudzikira nekuda kwekunyatso bvisa chip. Impact pane Akasiyana Industries:- Aerospace: maSwiss lathes anovimbisa chaiwo machining ezvikamu zvakakosha, kuwedzera kuchengetedzeka uye kuita.

- Midziyo Yezvokurapa: Yakanyanya kurongeka uye biocompatible zvinhu zvinoita kuti maSwiss lathes akoshese kugadzira ma implants ekurapa uye zviridzwa.

- Motokari: Nguva pfupi yekutenderera uye chaiyo machining inobatsira mukuvandudza mashandiro emotokari uye kuderedza mitengo.

- Electronics uye Microtechnology: Swiss lathes inogonesa kugadzirwa kwezvinhu zvakaomarara zve miniaturized zvigadzirwa zvemagetsi, zvichisangana nezvinodiwa tekinoroji yemazuva ano.

5.2. Kugumira uye Zvinetso

5.2.1. Kuoma: Swiss Type Lathes michina yakaoma inoda vashandi vane hunyanzvi uye vanogadzira zvirongwa. Zvinogumira: Kwekutanga kuseta uye hurongwa zvinogona kutora nguva uye zvinoda ruzivo rwakanyanya uye kudzidziswa. 5.2.2. Mutengo: Swiss lathes imari yakakosha, uye mutengo wavo wekutanga wekutenga unogona kunge wakakwira. Zvipimo: Mabhizinesi madiki anogona kuwana mutengo wekutanga unorambidza, kunyangwe kuwana kwekuita kunowanzo kupembedza mari. 5.2.3. Yakaganhurirwa Saizi Yebasa: maSwiss lathes akagadziridzwa machining akareba uye akatetepa workpiece. Mipimo: Iyo inogona kunge isingakodzeri akakura kana akawanda mazvikamu, achidzikamisa mashandisirwo azvo mune mamwe maindasitiri. 5.2.4. Kusarudzwa Kwezvinhu: Nepo maSwiss lathes achigona kubata zvakasiyana siyana, anogona kunge asiri iwo akanakisa sarudzo yezvakaoma zvakanyanya kana zvisinganzwisisike zvinhu. Mipimo: Mamwe maindasitiri anoda zvehunyanzvi angangoda kutsvaga dzimwe nzira dzekugadzira machining. 5.2.5. Setup Nguva Yekumhanya Diki: Swiss lathes inokunda mukugadzirwa kwevhoriyamu yakakwira asi inogona kunge iine nguva refu yekuseta yemitambo midiki yekugadzira. Zvinogumira: Kwekugadzira diki-batch, iyo nguva yekuseta inogona kumisa zvakanakira zvekumhanya-mhanya machining. 5.2.6. Tool Wear: Swiss lathes inoshandisa yakakwira spindle kumhanya, izvo zvinogona kutungamira mukupfeka kwezvishandiso. Zvinogumira:Kuwanzo chinja maturusi uye kugadzirisa kungave kuri madikanwa, zvichikanganisa kushanda kwese. Mukupedzisa, Swiss Type Lathes inopa zvinoshamisa mabhenefiti, anosanganisira kunyatsojeka, kumhanya, uye kuita zvakasiyana-siyana, zvichiita kuti ive yakakosha mumaindasitiri akasiyana. Zvisinei, havasi vasina ganhuriro dzavo nezvinetso, zvakadai sokuoma kunzwisisa uye mutengo. Izvo zvakakosha kuti unyatso funga izvi zvinhu kana uchitarisa kukodzera kweSwiss lathes kune chaiyo kugadzira zvinodiwa.Chikamu chechitanhatu: Emerging Technologies

Swiss Type Lathes haina kudzivirirwa kune tekinoroji kufambira mberi kweIndasitiri 4.0 uye zvigadzirwa / zvishandiso zvekushandisa. Ngationgororei kuti ma lathes aya ari kuchinjika sei kune ari kusimukira nyika:6.1. Indasitiri 4.0 Kubatanidzwa

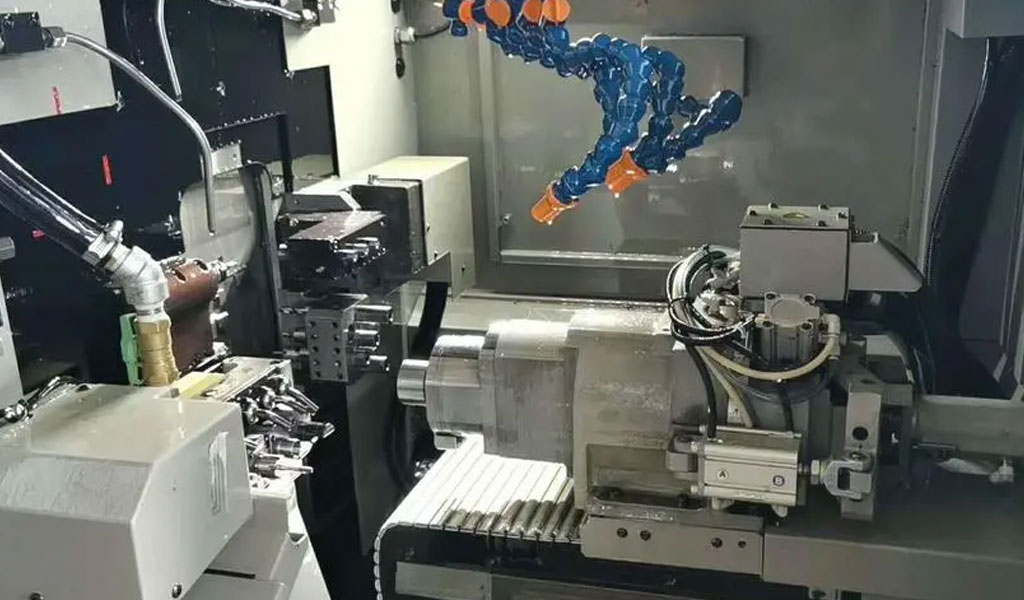

Swiss Type Lathes iri kuwedzera kubatanidza Indasitiri 4.0 misimboti, leveraging otomatiki, data analytics, uye yekubatanidza kusimudzira kugona kwavo: 6.1.1. Automation:- Kubatanidzwa nemarobhoti masisitimu kunobvumira mwenje-kunze machining, uko Swiss lathes inogona kushanda yakazvimirira 24/7.

- Zvakanakira: Kuwedzera kugadzirwa kwakanaka, kuderedzwa kwemitengo yevashandi, uye kuwedzera kushandiswa kwemuchina.

- Swiss Type Lathes ine ma sensors uye nzira dzekuunganidza data.

- Benefits: Chaiyo-nguva yekutarisisa kuita kwemuchina uye dhizaini yekugadzira, inobvumira dhata-inotyairwa kuita sarudzo uye maitiro ekugadzirisa.

- Predictive Maintenance: Data analytics inogonesa kufanotaura kwezvido zvekugadzirisa zvichibva pamamiriro emuchina, kuderedza nguva isina kurongeka.

- Swiss lathes inogona kubatana neKugadzira Kuuraya Systems (MES) kana iyo Industrial Internet yezvinhu (IIoT).

- Zvakanakira: Kukurukurirana kusina musono pakati pemichina uye masisitimu ekuronga kugadzirwa, manejimendi ezvinyorwa, uye kutonga kwemhando.

- Remote Monitoring: Vashandisi vanogona kutarisa mashandiro emuchina uye kugamuchira chenjedzo vari kure, vachivandudza kuterera.

- Digital twin tekinoroji inogadzira chaiwo replicas eSwiss Type Lathes.

- Benefits: Digital mapatya anobvumira epamberi simulations uye optimization, kuderedza kuseta nguva uye kuderedza zvikanganiso.

- Mazuva ano maSwiss lathes anoratidza mushandisi-ane hushamwari maficha uye ekubata zvikirini zveinonzwisisika hurongwa uye yekutarisa.

- Zvakanakira: Kuvandudzwa kwekushandisa uye kuderedzwa nguva dzekudzidzira kune vanoshanda.

6.2. Zvishandiso uye Tooling Innovations

Kufambira mberi mune zvekushandisa nekushandisa kuri kuwedzera kugona kweSwiss Type Lathes, zvichivagonesa kushanda nehupamhi hwemhando yezvigadzirwa uye kuwana chaiyo yepamusoro: 6.2.1. Advanced Materials:- Swiss Type Lathes vava kukwanisa kugadzira zvinhu zvepamberi senge macomposites, superalloys, uye ceramics.

- Benefits: Yakawedzerwa nzvimbo dzekushandisa, kunyanya mumaindasitiri emuchadenga nepamusoro-tekinoroji uko zvinhu izvi zvakapararira.

- Zvinetso: Machina epamberi zvinhu angangoda hunyanzvi hwekushandisa uye matekiniki nekuda kwezvakasiyana zvivakwa.

- Zvishandiso zvekupfeka sedhaimani-senge kabhoni (DLC) uye titanium nitride (TiN) inovandudza hupenyu hwematurusi uye kucheka mashandiro.

- Zvakanakira: Yakaderedzwa maturusi ekupfeka, yakagadziridzwa kupera kwepamusoro, uye nguva refu pakati pekuchinja kwechishandiso.

- Swiss lathes yakashongedzerwa nediki maturusi ekugadzira zvidiki, zvakaomarara zvikamu.

- Benefits: Yakanatsiridza kunyatsojeka kwemicrotechnology uye zvemagetsi maapplication.

- Yepamberi CAM software inogonesa yakakwana nzira yekugadzira yezvikamu zvakaomarara.

- Zvakanakira: Yakaderedzwa nguva yekutenderera, yakagadziridzwa kupera kwepamusoro, uye kushomeka kwezvishandiso zvekushandisa.

- Adaptive machining inoshandisa chaiyo-nguva data kugadzirisa kucheka paramita, optimize machining maitiro.

- Benefits: Kuvandudza kushanda nesimba, kuderedza kushandiswa kwesimba, uye hupenyu hwematurusi hurefu.

Chikamu 7: Mhedziso

7.1. Kudzokororwa Kwemapfundo Akakosha

Mukuongorora kwakadzama uku kweSwiss Type Lathes, takabata nyaya dzakasiyana siyana, kusanganisira kwadzinotangira, makanika, mashandisirwo, mashandisirwo, zvakanakira, zvinogumira, uye kubatana kwavo nehunyanzvi huri kusimukira. Heano maitiro akakosha ekutora:- Nhoroondo Midzi: Swiss Type Lathes ine mabviro ayo mukunyatso kudiwa kweiyo 19th-century yeSwiss yekugadzira wachi yeindasitiri, inoshanduka kuti ienderane nezvinodiwa zveakasiyana-siyana epamusoro ekugadzira zvikamu.

- hurongwa: Aya lathes anoratidzirwa neakaumbwa zvinhu senge musoro, gwara bushing, uye maturusi emidziyo, ine inotsvedza headstock michina yekunyatso uye inoshanda machining.

- Operations: Swiss Type Lathes inokunda mukudyisa zvinhu, kunyatsogadzira machining, kuronga, kutonhora, uye chip manejimendi, zvichiita kuti ive yakanakira maindasitiri anoda kunyatsojeka uye kushanda nesimba.

- Applications: Swiss Type Lathes inoita basa rakakosha mumhepo, kugadzira michina yekurapa, chikamu chemotokari, uye zvemagetsi uye microtechnology, kugadzira zvakakosha zvemaindasitiri aya.

- Advantages: Vanopa kunyatsojeka, kuderedzwa kutenderera nguva, kupedzwa kwakasarudzika kwepamusoro, kushanda panguva imwe chete, uye hunyanzvi hwekugadzirisa chip, zvinokanganisa maindasitiri akasiyana.

- Kugumira uye Zvinetso: Swiss Type Lathes inouya nematambudziko akadai sekuoma, mutengo, mashoma workpiece saizi, uye maturusi kupfeka. Kunyatsofungisisa kunodiwa pakusarudza iwo kune chaiwo maapplication.

- Emerging Technologies: Swiss Type Lathes iri kumbundira Indasitiri 4.0 kubatanidzwa, kubatanidza otomatiki, data analytics, uye kubatana. Zvishandiso uye zvishandiso zvekushandisa zviri kuwedzera kugona kwavo, zvichigonesa machining ezvigadzirwa zvepamberi uye kuwana chaiyo chaiyo.

7.2. Ramangwana Outlook

Ramangwana reSwiss Type Lathes rinotaridzika kuva rinovimbisa, rinotungamirwa nekuenderera mberi kwetekinoroji uye kusimudzira zvinodiwa zveindasitiri:- Indasitiri 4.0: Iko kubatanidzwa kweIndasitiri 4.0 tekinoroji ichaenderera mberi nekusimudzira Swiss Type Lathes 'kugona, kubereka, uye kuterera, zvichiita kuti zvive zvakanyanya kukosha mukugadzira kwemazuva ano.

- Materials Advancements: Sezvo maindasitiri achida zvinhu zvitsva zvine zvivakwa zvakasiyana, maSwiss lathes anochinjika kumashini aya zvinhu zvakanaka, achiwedzera nzvimbo dzawo dzekushandisa.

- Tooling Innovations: Zvishandiso zvinoramba zvichishanduka nekupfeka, miniaturization, adaptive machining, uye yakagadziridzwa nzira yekushandisa optimization, ichiwedzera kusimudzira uye kunyatsoita.

- Miniaturization Trend: Sezvo maindasitiri achisundira kuminiaturization, Swiss Type Lathes ichaita basa rakakosha mukugadzira zvinhu zvakaoma kunzwisisa zvemagetsi, zvishandiso zvekurapa, uye microtechnology.

- kuenderera: Kusimbisa kwekusimba mukugadzira kunotyaira Swiss lathes kutora eco-hushamwari maitiro uye kuderedza kushandiswa kwesimba.

Our Services

- 5 Sekaiichi machine

- Cnc Kugaya

- Cnc Kutendeuka

- Machining Maindasitiri

- Machining Maitiro

- Surface Kurapa

- Simbi yekushandisa

- Mapepa epurasitiki

- Upfu hweMetallurgy Mould

- Die Casting

- Zvikamu Garari

Case Studies

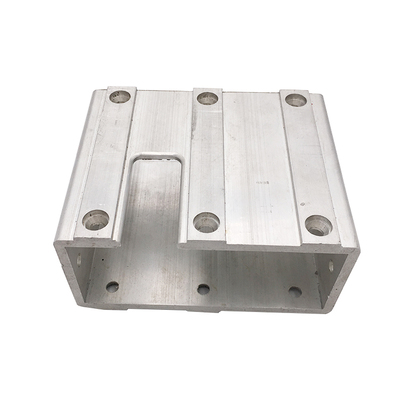

- Auto Metal Zvikamu

- Machinery Parts

- Akatungamira Heatsink

- Kuvaka Zvikamu

- Sravana Sameeralu Serial XNUMXth Mobile Parts

- Zvikamu Zvekurapa

- Zvikamu Zvemagetsi

- Zvichienderana machine

- Bicycle Parts

Chinyorwa Chinyorwa

- Aluminum machine

- Titanium Kubata

- Stainless Simbi machine

- Mhangura machine

- Brass machine

- Super chiwanikwa machine

- Peek Kugadzira

- UHMW machine

- Sanganisa Machining

- PA6 Kugadzira

- PPS machine

- Teflon Kugadzira

- Inconel machine

- Danho Simbi machine

- Zvimwe Zvinyorwa

Zvikamu Garari