Maitiro Ekuunganidza & Kuisa CNC Machine Zvishandiso Nzira Yakarurama uye Mazano Akanaka

2023-10-30

Chitsauko 1: Kunzwisisa CNC Machina

Muchitsauko chino, tichaisa hwaro nekuongorora kuti CNC michina chii, mhando dzakasiyana dziripo, uye zvakakosha zvinoumba muchina weCNC.a. Chii chinonzi CNC Machine?

Muchina weCNC, mupfupi weComputer Numerical Control muchina, ichidimbu chemidziyo inoshandiswa mukugadzira uye. machine kwachoes. Kusiyana nemichina yakajairwa inoshandiswa nemaoko nevashandi vevanhu, CNC michina inogadzirwa uye inodzorwa nemakomputa, ichibvumira kuita chaiko uye kudzokororwa zvakanyanya. Michina iyi inokwanisa kuita mabasa akaomarara sekucheka, kuchera, kugaya, uye kugadzira zvinhu zvakaita sesimbi, plastiki, huni nezvimwe. Papakati pemuchina weCNC kugona kwayo kududzira nekuita mirairo kubva pakombiyuta-inobatsira dhizaini (CAD) kana komputa-inobatsira kugadzira (CAM) software. Iyi software inogadzira nhevedzano yenhamba makodhi, anowanzo kunzi G-makodhi uye M-makodhi, ayo anoraira CNC muchina mafambisirwo ayo ekucheka maturusi uye workpiece kuti uwane mhedzisiro yaunoda. Michina yeCNC yakashandura maindasitiri ekugadzira nekuwedzera kushanda nesimba, kuderedza kukanganisa kwevanhu, uye kugonesa kugadzirwa kwezvinhu zvakaoma uye zvakagadziridzwa.b. Mhando dzeCNC Machina

CNC michina inouya mumhando dzakasiyana siyana, imwe neimwe yakagadzirirwa chaiyo maapplication uye maindasitiri. Heano mamwe marudzi akajairika eCNC michina:- cNC hwokugaya hwakabvira Michina: Michina iyi inoshandiswa kucheka nekugadzira zvinhu nekutenderedza maturusi ekucheka. Ivo vanoshandiswa zvakanyanya mumaindasitiri akadai seaerospace, mota, uye kugadzira simbi kumabasa akaita sekuchera, kugaya, uye kunyora.

- CNC Lathes: CNC lathes akagadzirirwa kutenderedza workpiece nepo kucheka chishandiso chinoshandiswa kubvisa zvinhu kubva mairi. Izvo zvakakosha pakugadzira cylindrical components, zvakadai se mugodhis and bushings.

- CNC routers: Michina iyi inonyanya kushandiswa kucheka nekugadzira zvinhu zvakaita sehuni, mapurasitiki, uye macomposites. CNC ma routers akajairika mumaindasitiri ekugadzira matanda uye masaini.

- CNC Plasma Cutters: Yakanakira kucheka simbi mashizha, CNC plasma cutters vanoshandisa high-velocity jet ye ionized gasi kunyunguduka uye kubvisa zvinhu. Ivo vanoshandirwa mukugadzira simbi uye maindasitiri emotokari.

- CNC Laser Cutters: Laser yekucheka michina inoshandisa yakakwirira-powered laser danda kunyatso kucheka kana kunyora zvakasiyana zvinhu, zvinosanganisira simbi, mapurasitiki, uye machira. Ivo vanowana maapplication mumaindasitiri kubva pakugadzira zvishongo kusvika kumaindasitiri ekugadzira.

- CNC Waterjet Cutters: Vateki veWaterjet vanoshandisa rwizi rwakanyanya-kudzvanywa kwemvura yakasanganiswa neabrasive particles kucheka nepakati zvinhu. Izvo zvakakodzera kucheka zvakasiyana-siyana zvezvinhu, kusanganisira dombo, girazi, uye simbi.

- CNC EDM Machina: Electrical Discharge Machining (EDM) michina inoshandisa madhirigi emagetsi kuti abvise zvinhu kubva pane workpiece. Iyo inoshandiswa kune yakaoma uye yakakwirira-chaiyo mabasa, kunyanya mumidziyo uye kufa kugadzira.

c. Zvikamu zveCNC Machine

Kunzwisisa zvikamu zvemuchina weCNC kwakakosha pakushanda kwakanaka uye kugadzirisa. Heano akakosha ezvikamu anowanikwa mumazhinji CNC michina:- Machine Frame: Iyo muchina furemu inopa tsigiro yezvimiro kune yese CNC muchina. Inowanzo kugadzirwa nezvinhu zvinorema-basa kuti ive nechokwadi chekugadzikana uye kusimba panguva yekushanda.

- Chokurukisa: Iyo spindle chinhu chine mota ine basa rekubata uye kutenderedza kucheka maturusi kana zvakabatanidzwa. Inoita basa rakakosha mukurongeka kwemachining uye nekumhanya.

- Axis System: Michina yeCNC inoshanda pamwe nematemo akawanda, kazhinji akanyorwa kuti X, Y, uye Z. Matemo aya anotsanangura mafambiro emuchina munzvimbo ine mativi matatu. Mimwe michina inogona kunge iine mamwe mademo ekutenderera, senge A, B, uye C, kune mamwe maoperation akaoma.

- Tool Changer: Michina yakawanda yeCNC ine otomatiki maturusi ekuchinja anobvumira kukurumidza kuchinjika kwekucheka maturusi panguva yekugadzira machining. Izvi zvinovandudza kushanda zvakanaka uye kuderedza nguva.

- Panel Kudzora: Iyo control panel ine interface iyo vashandisi kana vanogadzira mapurogiramu vanogona kuisa mirairo, kurodha zvirongwa, uye kutarisa mamiriro emuchina.

- Worktable kana Workholding System: Iyo worktable ndiyo iyo workpiece inobatwa zvakachengeteka panzvimbo panguva yekugadzira. Zvishandiso zvakasiyana-siyana zvekushanda, senge clamps, vises, uye zvigadziri, anoshandiswa kuve nechokwadi chekuti workpiece inoramba yakagadzikana uye yakamira zvakanaka.

- Dhiraivha Sisitimu: Iyo drive system inosanganisira mota uye ma actuators ane basa rekufambisa zvinhu zvemuchina pamwe nematemo akatsanangurwa. Kunyatso kudzora kwedhiraivha system kwakakosha pakugadzira kwakaringana.

- Inotonhorera System: Kutonhora kunokosha panguva Multi Axis Cnc Machining kudzivirira kupisa kwezvishandiso uye workpieces. CNC michina kazhinji ine inotonhorera sisitimu panzvimbo yekuchengetedza yakanyanya tembiricha.

- Kudzora Kombuta: Iyo komputa inodzora inogara hardware uye software inodiwa pakumhanyisa CNC muchina. Inodudzira iyo G-makodhi uye M-makodhi anogadzirwa neCAD/CAM software uye inoashandura kuita mafambiro nezviito.

Chitsauko 2: Pre-Instalation Kugadzirira

Usati watanga kuisirwa CNC muchina wako, zvakakosha kuti uite gadziriro yakakwana. Ichi chitsauko chinokutungamirira kuburikidza neakakosha pre-kugadzwa kufunga, kusanganisira kuseta nzvimbo yebasa, simba nemagetsi zvinodiwa, uye matanho ekuchengetedza kuti uve nechokwadi chekugadzika uye kwakachengeteka maitiro.a. Kufunga nezvenzvimbo yebasa

- Space Zvinodiwa: Tanga nekuongorora nzvimbo iripo muwekishopu yako kana nzvimbo. Ita shuwa kuti nzvimbo yacho yakapamhama zvakakwana kuti igare muchina wako weCNC, kusanganisira nzvimbo yakakwana yekuwana nekuchengetedza. Funga nezvehukuru hwemuchina, nzvimbo inodiwa pakubata zvinhu, uye chero mimwe michina kana nzvimbo dzekushandira.

- Kubhururuka: Kufefetera kwakakwana kwakakosha kubvisa kupisa kunoitwa panguva yekugadzira uye kubvisa chero hutsi hunogona kukuvadza kana guruva. Isa masisitimu ekufemesa kana kuti midziyo yekusefa mhepo sezvinodiwa kuchengetedza nzvimbo yekushanda yakachena uye yakachengeteka.

- Flooring: Ita shuwa kuti pasi munzvimbo yakatarwa yakaenzana, yakagadzikana, uye inokwanisa kutsigira huremu hwe CNC muchina. Kusaenzana kana kusasimba pasi kunogona kutungamira kumichina kuzunguzika uye kusarongeka panguva yekushanda.

- Accessibility: Ronga yekuwana nyore kumuchina weCNC yekuisa, kugadzirisa, uye kugadzirisa. Ita shuwa kuti pane nzira dzakajeka uye nzvimbo yakakwana yekufambisa inorema michina uye zvinhu.

- Taa: Mwenje wakakwana wakakosha pakushanda kwakachengeteka uye kwakaringana. Ita shuwa kuti nzvimbo yekushandira yakavhenekerwa zvakanaka kudzivirira tsaona uye kupa kuoneka kwakajeka kwemaitiro ekugadzira.

b. Simba neMagetsi Zvinodiwa

- Electrical Supply: Sarudza izvo zvemagetsi zvinodiwa pamushini wako weCNC. Tarisa uone tekinoroji yemuchina uye bvunza mugadziri kana mutengesi kuti uone kuti magetsi enzvimbo yako anozadzisa izvi zvinodiwa.

- Voltage uye Phase: Michina yeCNC ingada mazinga akasiyana emagetsi (semuenzaniso, 110V, 220V, 440V) uye zvikamu (chikamu chimwe chete kana nhatu-chikamu). Ita shuwa kuti magetsi anoenderana nezvinodiwa nemuchina.

- Electrical Panel: Isa yakazvipira yemagetsi pani yemuchina weCNC kudzivirira kuremedza maseketi aripo. Shandisa mugadziri wemagetsi ane rezenisi kuti abate wiring nekubatanidza zvine hunyanzvi.

- Kuchengetedzwa kwekudzivirira: Chengetedza mari mumidziyo yekudzivirira yekuvhiya kuchengetedza iyo CNC muchina wemagetsi zvinhu zvemagetsi kubva pakuchinja kwemagetsi uye magetsi emagetsi.

- Grounding: Ita shuwa kudzika kwakaringana kwema CNC muchina uye hurongwa hwemagetsi kudzikamisa njodzi yenjodzi dzemagetsi uye kukuvara kwemidziyo.

c. Matanho Okuchengetedza

- Zvokuchengetedza Zvokushandisa: Isa chengetedzo pamberi nekupa yakakodzera midziyo yekudzivirira yemunhu (PPE) yevashandisi uye matekiniki. Izvi zvinogona kusanganisira magirazi ekudzivirira, kudzivirira kunzwa, magirovhosi, uye zvipfeko zvinodzivirira.

- Emergency Procedures: Gadzira uye unyore nzira dzekumisikidza dzekumisikidza dzinogona kukurumidza kumisa muchina weCNC kana zviitiko zvisingafanoonekwi kana tsaona. Ita shuwa kuti vashandi vese vakadzidziswa maitiro aya.

- Kuchengetedza Kwemoto: Isa zvinodzimisa moto uye zvinoona utsi munharaunda yemuchina weCNC. Shandisa mitemo yekuchengetedza moto, sekuchengeta zvinhu zvinopisa zviri kure nemuchina uye kuchengetedza hurongwa hwekubuda kwemoto.

- Kukiya/Tagout (LOTO): Shandisa LOTO maitiro ekudzivirira netsaona muchina kutanga panguva yekugadzirisa kana kugadzirisa. Shandisa makiyi uye ma tag kuratidza kana muchina uri kuita sevhisi.

- Dzidzo Yekuchengetedza: Ita dzidziso yakakwana yekuchengetedza kune vese vashandi vanozoshanda, kuchengetedza, kana kushanda vakatenderedza CNC muchina. Simbisa maitiro akachengeteka uye kukosha kwekutevera kuchengetedzwa kweprotocol.

- Rubatsiro rwekutanga: Chengetedza kit yerubatsiro rwekutanga yakanyatsochengetedzwa padyo nemuchina weCNC. Ita shuwa kuti vashandi vakadzidziswa varipo kuti vape rubatsiro rwekutanga rwekukurumidza kana vakakuvara.

Chitsauko 3: Kuunganidza iyo CNC Machine

Kana uchinge wapedza gadziriro dzepre-installation, inguva yekuenderera mberi kune chikamu chegungano. Muchitsauko chino, isu tinopa nhanho-ne-nhanho gwara rekuunganidza yako CNC muchina, inovhara akakosha mabasa kubva pakuburitsa uye kuongorora kusvika kune tambo manejimendi.a. Kusunungura uye Kuongorora

- unboxing: Tanga nekunyatso kuburitsa zvese zvikamu zve CNC muchina wako. Tevedzera mirairo yemugadziri wekuburitsa kuti usave nekukuvadzwa mukati mekuita. Shandisa maturusi akakodzera uye zvokusimudza kana zvichidiwa.

- Component Inventory: Gadzira chinyorwa chekuongorora kuti uone kuti wagamuchira zvese zvikamu zvakanyorwa mubhuku remuchina kana zvinyorwa. Iva nechokwadi chekuti hapana chisipo kana kukuvara.

- Ongorora Zvakaipa: Nyatsoongorora chikamu chega chega pane chero zviratidzo zvekukuvadzwa, senge mazino, zvikweshwa, kana zvikamu zvakabhenda. Nyora chero nyaya uye zivisa mugadziri kana mutengesi nekukurumidza.

b. Kuronga Zvikamu

- Ronga Nzvimbo Yebasa: Usati wasangana, ita shuwa kuti nzvimbo yako yekushandira yakachena uye yakarongeka. Bvisa chero clutter uye ipa yakakwana nzvimbo yekuisa kunze uye kuronga zvikamu.

- Boka Zvikamu Zvakafanana: Unganidza zvikamu zvakafanana pamwechete kuti ufambise basa regungano. Zvikamu zvakadai fasteners, mabhuraketi, uye Hardware zvinofanirwa kurongeka mumidziyo yakasiyana kana matireyi kuti ive nyore kupinda.

- Tarisa kune Manuals: Ongorora zvinyorwa zvegungano uye zvinyorwa zvinopihwa nemugadziri. Zvijaire nematanho egungano, madhayagiramu, uye chero mirairo chaiyo.

c. Kubatanidza iyo Machine Frame

- Base Gungano: Tanga nehwaro hwe CNC muchina. Tevera mirairo yemugadziri kuti uunganidze base frame zvakachengeteka. Ita shuwa kuti yakaenzana uye yakagadzikana.

- Column uye Zvimiro Zvekutsigira: Unganidza mbiru uye zvigadziro zvekutsigira, uzvienzanise nemazvo nehwaro. Simbisa mabhaudhi ese uye zvisungo kune zvakakurudzirwa torque kukosha.

- Nhungamiro uye Rails: Isai magwara uye njanji inotungamira mafambiro emuchina wekucheka kana maturusi ekubata zvinhu. Ita shuwa kuti dzakanyatsoenderana uye dzakabatanidzwa zvakachengeteka.

d. Kubatanidza Motors uye Drives

- Kuiswa kweMota: Isa mamotor munzvimbo dzawo dzakatarwa maererano nemirairo yemugadziri. Ita shuwa kuti mota dzakasungirirwa zvakachengeteka uye dzakaenderana nemaitiro ekutyaira.

- Dhiraivha Sisitimu: Batanidza mamotor kune madhiraivha maitiro uchishandisa akakodzera couplings kana mabhandi. Ita shuwa kusawirirana kwakakodzera uye kurongeka kudzivirira backlash uye zvisizvo.

e. Kuisa Control Panel

- Control Panel Mounting: Isa iyo control panel munzvimbo iri nyore, kazhinji mukati mekusvika nyore kweanoshanda. Ita shuwa kuti yakaiswa zvakachengetedzeka uye yakamisikidzwa kuti inyatso kuoneka uye kuwanikwa.

- Kukoneswa Kwemagetsi: Batanidza control panel kumagetsi emuchina uchitevera madhayagiramu ewaya akapihwa muzvinyorwa zvemugadziri. Ongorora kaviri zvese zvinongedzo kuti ndezvechokwadi.

f. Cable Management

- Cable Routing: Nyatsofambisa tambo dzose, waya, uye hose nenzira yakarongeka kudzivirira kudhumhana kana kukanganisa nezvikamu zvinofamba. Shandisa matireyi etambo kana zvimedu kuchengetedza nekudzivirira tambo.

- Kunyora: Nyora tambo newaya zvine mamakisi kana ma tag kurerutsa kugadzirisa nekugadzirisa. Maka zvakajeka chinangwa chetambo yega yega uye kwairi kuenda.

- Kuedzwa: Usati wavhara chero zvakavharirwa kana mapaneru, ita bvunzo yekutanga kuti uone kuti ese magetsi ekubatanidza ari kushanda nemazvo. Iva nechokwadi chekuti mota nema sensors anopindura sezvaitarisirwa.

Chitsauko 4: Kurongedza uye kuenzana

MuChitsauko 4, isu tichanyura mune yakakosha maitiro ekugadzirisa uye kuenzanisa muchina wako weCNC. Kurongeka kwakaringana uye kuyera kwakakosha pakuita kuti huroyi uye huroyi hwemashandiro emuchina wako. Ichi chitsauko chinobata kukosha kwekuenzanisa uye kuenzana, maturusi nemidziyo inodiwa, uye nhanho-ne-nhanho gwara rekugadzirisa uye nhanho maitiro.a. Kukosha Kwekugadzirisa uye Kuenzana

- Kururama uye Kurongeka: Kurongeka uye kuyera kwakakosha kuti uwane iyo yakakwira dhigirii yekurongeka uye kurongeka kunodiwa muCNC machining. Kusarongeka kana kusaenzana kunogona kutungamirira kune zvikanganiso zvedimensional mune zvakapedzwa workpieces.

- Yakaderedzwa Kupfeka uye Kucheuka: Kurongeka kwakakodzera kunoderedza kusagadzikana kusingakoshi pamichina yezvikamu, senge kutakuras uye nzira. Izvi zvinorebesa hupenyu hwemuchina uye zvinoderedza mari yekugadzirisa.

- Minimized Vibration: Muchina wakanyatsorongeka uye wakamisikidzwa unoburitsa mavibrations mashoma, zvichikonzera kupera kuri nani kwepamusoro uye kuderedzwa kwezvishandiso. Vibrations inogonawo kukanganisa hupenyu hurefu hwezvinhu zvemagetsi zvinonzwisisika.

- Kudzivirirwa: Michina isina kurongeka kana kuti isina mwero inogona kuunza njodzi dzekuchengetedza. Semuyenzaniso, muchina usina chiyero unogona kupenengura kana kufamba zvisingatarisirwi panguva yekushanda.

b. Zvishandiso Nemidziyo Inodiwa

Kuti uite kurongeka uye kuyera nenzira kwayo, iwe uchada zvinotevera maturusi nemidziyo:- Precision Levels: Yepamusoro-yemhando yepamusoro mazinga akakosha pakuyera nemazvo kurongeka kwemuchina uye kuenzana.

- Zvishandiso zvekugadzirisa: Zvichienderana nekugadzirwa kwemuchina wako, unogona kuda maturusi chaiwo senge mawrench, shims, kana gadziriso screws.

- Dial Indicators: Dial zviratidzo zvinobatsira mukuyera kurongeka kweakasiyana makina emidziyo, kusanganisira iyo sosi spindle uye inoshanda.

- Feeler Gauges: Mafeeler geji anoshandiswa kuyera mapundu uye kucheneswa pakati pezvikamu zvemuchina panguva yekuenzanisa.

- Alignment Laser: Iyo alignment laser inogona kubatsira pakuongorora kutwasanuka kwegwara uye zvimwe mutsara zvikamu.

c. Nhanho-ne-Nhanho Kurongeka uye Kuenzana Maitiro

Tevedza nhanho idzi kurongedza uye kuyera CNC muchina wako:Danho 1: Gadzirira Nzvimbo Yebasa

Ita shuwa kuti nzvimbo yekushandira yakachena, haina tsvina, uye ine chiedza chakanaka. Bvisa chero zvipingamupinyi zvinogona kukanganisa kurongeka uye kurongeka.Danho rechipiri: Reference Point Establishment

Sarudza nzvimbo yakagadzikana yereferensi pamushini kana chigadziko, kazhinji chinopihwa nemugadziri. Iyi poindi ichashanda senzvimbo yekutanga yezviyero zvese.Nhanho 3: Level the Machine

- Isa mazinga chaiwo pane akasiyana siyana emuchina, senge base, makoramu, uye worktable.

- Rongedza maseruru ekuyera kana shims sezvinodiwa kuti uwane kurongeka kwakaringana. Tarisa mabubble zviratidzo pamatanho echokwadi.

Nhanho 4: Kurongeka kweNhungamiro uye Masiraidhi

- Shandisa dial zviratidzo uye alignment lasers kutarisa kutwasanuka uye parallelism yegwara, masiraidhi, uye zvimwe mutsara zvikamu.

- Rongedza zvikamu zvakakodzera kugadzirisa chero kusarongeka kwakaonekwa.

Nhanho 5: Spindle Alignment

- Isa chinongedzo chekudaira pane spindle yemuchina kana chibatiso chemudziyo.

- Tenderedza chirungiso kuti utarise kuti hapana kupera uye kudzika. Gadzirisa spindle sezvinodiwa kuti uderedze runout.

Danho rechitanhatu: Worktable Alignment

- Tarisa kurongeka kwetabhenakeri yebasa kana yekushanda uchishandisa dial zviratidzo.

- Rongedza chinzvimbo chetabhebhurosi kuti ive nechokwadi chekuti iri perpendicular kumasemo emuchina.

- Mushure mekugadzirisa, tarisazve zvese zvigadziriso kuti uone kuti zvinosangana neyakatemwa kushivirira.

- Ita bvunzo inomhanya kuona kuti muchina unoshanda nemazvo uye unoburitsa mhedzisiro yaunoda.

Danho rechina: Zvinyorwa

Chengetedza marekodhi akadzama ekugadzirisa uye kuyera maitiro, kusanganisira kuyerwa, kugadzirisa kwakaitwa, uye chero nyaya dzakasangana. Izvi zvinyorwa zvichave zvakakosha kune ramangwana rekutarisa nekugadzirisa.Nhanho 9: Yekupedzisira Kuongorora uye Certification

Funga kuve nenyanzvi kana mainjiniya ane hunyanzvi hwekuongorora uye chitupa kuti ave nechokwadi chekuti muchina weCNC unosangana nezviyero zveindasitiri uye zvinodiwa zvekuchengetedza. Kurongeka kwakaringana uye kuyera kwakakosha kune yakavimbika uye kwakaringana mashandiro emuchina wako weCNC. Tora nguva yako mukati mekuita uku, sezvo kurongeka kwakakosha. Nekutevera nhanho idzi uye kushandisa maturusi akakodzera, unogona kuve nechokwadi chekuti muchina wako uri muchimiro chakakwana chekubudirira machining mashandiro. Muchitsauko chinotevera, tichaongorora zvinodiwa nemagetsi wiring yemuchina wako weCNC.Chitsauko 5: Magetsi Wiring

Muchitsauko chino, isu tichaongorora mukati memagetsi wiring maficha eCNC yekumisikidza muchina wako. Wiring yemagetsi yakakodzera yakakosha pakuchengetedza uye kushanda zvakanaka kwemuchina. Ichi chitsauko chinobata kunzwisisa masisitimu emagetsi, wiring yemuchina weCNC, uye zvakakosha kuchengetedza.a. Kunzwisisa Electrical Systems

- Magetsi: CNC michina inoda yakagadzikana uye yakakodzera magetsi emagetsi. Nzwisisa voltage, frequency, uye chikamu zvinodiwa zvinotsanangurwa nemugadziri wemuchina. Iva nechokwadi chekuti magetsi akavimbika uye ane simba rakakwana rekubata mutoro wemagetsi emuchina.

- Electrical Panel: Michina yakawanda yeCNC ine pani yemagetsi inogara zvinhu zvakasiyana-siyana, zvinosanganisira mabreaker breakers, relays, contactors, uye terminal blocks. Zvijaire nezvikamu zviri mupanera uye nemabasa avo.

- Wiring Diagrams: Ongorora madhayagiramu e wiring anopihwa nemugadziri wemashini. Aya madhayagiramu anoratidza kubatana kuri pakati pezvikamu uye akakosha pakugadzirisa waya.

- Grounding: Kudzika kwakakodzera kwakakosha pakuchengeteka. Ita shuwa kuti muchina uye hurongwa hwemagetsi zvakadzikwa zvinoenderana nemakodhi emagetsi emunharaunda uye kurudziro yemugadziri.

b. Wiring iyo CNC Machine

Tevedza matanho aya kuti waya waya CNC muchina wako:Danho 1: Power Off

Ita shuwa kuti muchina uye sosi yemagetsi zvakadzimwa usati watanga chero basa re wiring. Bvisa muchina kubva pamagetsi.Danho 2: Wiring Plan

Gadzira chirongwa che wiring chinoenderana neanogadzira wiring diagrams. Ziva izvo zvinoumba, zvakaita semotor, sensors, switch, uye control panel, uye tarisa kubatana kwavo.Danho rechitatu: Cable Selection

Shandisa tambo dzakakodzera uye waya dzinosangana nemagetsi emuchina uye zvinodiwa pazvino. Ita shuwa kuti tambo ndedzegeji chaiyo uye rudzi rwekudzivirira.Danho 4: Cable Routing

Nyatsofambisa tambo newaya pamwe chete nematireyi etambo emuchina kana makondiiti. Zvichengetedze zvakarongeka uye zvakaparadzana kubva kune zvinofamba zvikamu kudzivirira kukuvara.Nhanho 5: Terminal Connections

Batanidza waya kune akakodzera materminal pazvikamu zvakaita semotor, sensors, uye switch. Iva nechokwadi chekubatana kwakachengeteka necrimping kana soldering sezvinodiwa. Shandisa mavara ewaya kuti zvizivikanwe zviri nyore.Danho 6: Control Panel Wiring

Mukati medhizaini yekudzora, batanidza waya kune akateedzana terminal mabhuroki, edunhu mabhuroki, macontactor, uye relays sekutsanangurwa kweiyo wiring diagram. Iva akangwarira pabasa rako kudzivirira machinjiro-mabatiro kana mawaya asina kusimba.Danho 7: Power Supply Connection

Batanidza muchina kune magetsi uchitevera gwara remugadziri. Tarisa kaviri voltage, chikamu, uye frequency kusetwa kuti uone kuti inowirirana nezvinodiwa nemuchina.Danho rechisere: Matanho ekuchengetedza

Shandisa kuchengetedza zvinhu zvakadai sechimbichimbi stop switch uye kuchengetedza interlocks sezvinodiwa. Ita shuwa kuti aya maturusi ekuchengetedza ane waya nemazvo uye akaedzwa kushanda.Danho 9: Kuedza

Usati wavhara control panel uye nekusimbisa muchina, ita bvunzo yekuenderera kuti utarise chero kukanganisa kwewaya kana mapfupi maseketi. Ita shuwa kuti zvese zvinongedzo zvakachengeteka uye hazvina tambo dzakasununguka.c. Chengetedzo Yekuchengetedza

- Kukiya/Tagout (LOTO): Shandisa LOTO maitiro ekudzivirira netsaona muchina kutanga panguva ye wiring kana kugadzirisa mabasa. Midziyo yekuvhara inofanirwa kushandiswa kupatsanura magetsi ega.

- Anokwanisa Magetsi: Basa remagetsi rinofanirwa kuitwa nenyanzvi yemagetsi kana technician anoziva nezvezvinodiwa zvemagetsi emuchina uye macode emagetsi emunharaunda.

- Overload Protection: Isa zvidziviriro zvinodzivirirwa zvakawandirwa zvakafanira, zvakaita semagetsi edunhu kana mafuse, kudzivirira kukuvadzwa kana ukakanganisa magetsi.

- Grounding: Ita shuwa kuti muchina uye zvese zvikamu zvemagetsi zvakadzika zvakanaka kudzivirira njodzi dzemagetsi.

- Kunyora: Nyora zvakajeka waya dzese, tambo, uye zvikamu kuti zvifambise kugadzirisa uye kugadzirisa mune ramangwana.

- Kugara Kuongorora: Nguva nenguva ongorora hurongwa hwemagetsi kuona zviratidzo zvekusakara, kukuvadzwa, kana kusununguka. Gadzirisa chero nyaya nekukasika.

- Emergency Procedures: Gadzira uye taura nzira dzekukurumidzira dzenyaya dzemagetsi, kusanganisira moto wemagetsi kana zviitiko zvemagetsi.

Chitsauko 6: Kuisa iyo Kudzora Software

Muchitsauko chino, tichaongorora nzira yekuisa yekudzora software yemuchina wako weCNC. Iyo yekudzora software ndiyo uropi hweCNC system yako, ine basa rekududzira nekuita iwo machining mirairo. Chitsauko ichi chinobata mucherechedzo weCNC muchina wekudzora software, nhanho-ne-nhanho gwara rekumisikidza software, uye calibration uye kuyedza maitiro.a. CNC Machine Control Software Overview

- Basa reKudzora Software: CNC muchina inodzora software ine basa rekushandura dhizaini uye dhata rekushandisa kubva kuCAD/CAM software kuita chaiyo muchina mafambiro. Iyo inogadzira iyo G-makodhi uye M-makodhi anoraira mota dzemuchina uye ma actuators.

- Mhando dzeKudzora Software: Kune akasiyana marudzi eCNC control software, kubva kune proprietary software yakapihwa nevagadziri vemuchina kune yakavhurika-sosi uye yechitatu-bato mhinduro. Sarudza software inoenderana nezvido zvemuchina wako uye kuziva kwako nechimiro chayo.

- Features: Kudzora software kunogona kusiyana maererano nemaitiro uye kugona. Tsvaga software inopa mashandisirwo anodiwa kune ako chaiwo machining zvaunoda, senge chizvarwa cheturusi, shanduko yekushandisa, uye spindle kumhanya kudzora.

b. Nhanho-ne-Nhanho Kuiswa kweSoftware

Tevedza matanho aya kuti uise software yekudzora yemuchina wako weCNC:Danho 1: System Zvinodiwa

Tarisa zvinodiwa nehurongwa zvinotsanangurwa nemugadziri wesoftware. Ita shuwa kuti komputa yako inosangana nezvinodiwa izvi maererano nehardware, inoshanda sisitimu, uye iripo ndangariro.Danho 2: Kurodha Software kana Kuisa Media

Tora software yekudzora kungave nekuidhawunirodha kubva kuwebhusaiti yemugadziri kana kushandisa yekuisa midhiya inopihwa nemugadziri.Danho 3: Kuiswa

- Tinya kaviri pane software yekuisa faira kuti utange iyo yekuisa.

- Tevedza mirairo yepa-screen inopihwa nemuisi. Izvi zvinogona kusanganisira kusarudza madhairekitori ekuisa, kugamuchira zvibvumirano zverezinesi, uye kugadzirisa zvirongwa zvesoftware.

- Ita shuwa kuti kuisirwa kwabudirira, uye hapana zvikanganiso zvinosangana.

Nhanho 4: Kupa marezinesi uye Activation

Kana iyo software yekudzora ichida rezinesi kana activation, tevera nhungamiro yemugadziri kuti upedze kuita uku. Ita shuwa kuti une makiyi erezinesi anodiwa kana macode activation.Danho 5: Machine Configuration

Gadzirisa iyo yekudzora software kuti ienderane neiyo CNC muchina wako. Izvi zvinogona kusanganisira kuseta maparamita ematemo emuchina, mhando dzemota, uye zvimwe zvinhu zvehardware.Danho 6: Chishandiso uye Material Database

Gadzira kana pinza chishandiso uye dhatabhesi yezvinyorwa musoftware yekudzora. Ruzivo urwu rwakakosha pakugadzira nzira yezvishandiso uye kusarudza yakakodzera machining paramita.c. Calibration uye Testing

Mushure mekunge software yekudzora yaiswa, tevera matanho aya ekugadzirisa uye kuyedzwa:Nhanho 1: Homing uye Reference Point Setup

- Kumba muchina nekufambisa mbezo dzese kune yavo referensi kana nzvimbo dzemba. Izvi zvinogadzira nzvimbo inozivikanwa yekutangisa mafambiro emuchina.

- Wona kuti muchina wadzokera kunzvimbo yereferensi nemazvo.

Danho 2: Tool Calibration

- Gadzirisa kureba kwechishandiso uye dhayamita yechishandiso. Izvi zvinova nechokwadi chekuti muchina unoziva makuriro chaiwo ematurusi auchashandisa.

- Ita bvunzo yekucheka kana chishandiso chekubata-kubvisa maitiro kuti usimbise chiyero cheturusi.

Danho 3: Workpiece Setup

- Chengetedza bvunzo yekushanda kana zvinhu pamushini wekushanda kana yekushanda system.

- Ita shuwa kuti workpiece yakanyatsoenderana uye yakachengetedzwa.

Nhanho 4: Test Inomhanya

- Rodha chirongwa chakareruka chekuyedza musoftware yekudzora.

- Mhanyai chirongwa chekuyedza kuona mafambiro emuchina uye machining zvabuda.

- Tarisa kune chero nyaya dzakadai sekufamba kusingatarisirwe, kubonderana kwezvishandiso, kana kusarongeka.

Danho 5: Kunyatsogadzirisa

Kana nyaya dzikaonekwa panguva yekuyedzwa, gadzirisa zvigadziriso zvesoftware, zvigadziriso zvematurusi, kana setup yebasa sezvinodiwa. Dzokorora bvunzo inomhanya kusvika muchina waita nemazvo uye nekuvimbika.Danho rechina: Zvinyorwa

Nyora zvese calibration uye bvunzo mhinduro, kusanganisira chero zvigadziriso zvakaitwa kune control software. Mapepa aya akakosha kune ramangwana uye kugadzirisa matambudziko. Kuiswa kwekutonga software inhanho yakakosha muCNC yekuseta muchina. Nekutevera mirairo yemugadziri, kuenzanisa muchina, uye kunyatsoyedza, unogona kuona kuti CNC muchina wako wakagadzirira kugadzirwa uye unokwanisa kuburitsa chaidzo uye nemazvo mhedzisiro. Muchitsauko chinotevera, tichaongorora kukosha kwekuzora uye kugadzirisa mukuchengetedza kuita uye hupenyu hurefu hwemuchina wako weCNC.Chitsauko 7: Mafuta uye Maintenance

Muchitsauko chino, isu tichatarisa pane akakosha maficha ekuzora uye kugadzirisa kune yako CNC muchina. Kuzora kwakaringana uye kugadzirisa nguva dzose kwakakosha pakuita kuti hurefu, huchokwadi, uye kuvimbika kwemidziyo yako yeCNC. Tichavhara kukosha kwekuzora, nzvimbo dzekuzora, uye nekumisikidza chirongwa chekugadzirisa.a. Sei Kuzora kwakakosha

Lubrication inoita basa rakakosha mukuita uye hupenyu hurefu hwe CNC muchina wako nekuda kwezvikonzero zvakati:- Kuderedzwa kweFriction: Kuzora kunoderedza kupokana pakati pezvikamu zvinofamba, zvakaita semabheya, magwara, uye masiruuru ebhora. Izvi zvinoderedza kusakara uye kubvaruka pazvinhu, zvichiwedzera hupenyu hwavo.

- Kubvisa Kupisa: Mafuta anobvisa kupisa kunogadzirwa panguva yekugadzira, kudzivirira kupisa kwezvikamu zvakakosha. Izvi zvinobatsira kuchengetedza dimensional kurongeka uye kuderedza njodzi yekuwedzera kwekupisa.

- Smooth Kushanda: Kuzora kwakaringana kunovimbisa kufamba kwakapfava uye kwakanyatsojeka kwezvikamu zvemuchina. Izvi zvakakosha kuti uwane iyo yakanyanya kurongeka inodiwa muCNC machining.

- Kudzivirira Corrosion: Mafuta ekuzora anopa chipingamupinyi chinodzivirira kubva pakunyorova uye zvinosvibisa, zvichideredza njodzi yekuora panzvimbo dzesimbi.

- Rudzi rweRucheno: Lubrication inogona kuderedza ruzha runogadzirwa panguva yekushanda kwemuchina, ichigadzira nzvimbo yakanyarara uye yakagadzikana yekushanda.

b. Lubrication Points

Yakasiyana CNC michina ine akasiyana lubrication mapoinzi anoda kutariswa. Heano mamwe mapoinzi ekuzora akajairika ekufunga nezvawo:- Linear Guideways: Isa lubricant kune mitsara inotungamira, iyo inofambisa kufamba kwemasanhu emuchina. Izvi zvinogona kusanganisira bhora screws, linear bearings, uye masiraidhi.

- Spindle Bearings: Zora mabhengi ekutenderera kuti ave nechokwadi chekutenderera uye kuderedza kukweshera panguva yekucheka kana machining mashandiro.

- Tool Changer Mechanism: Kana muchina wako uine otomatiki chishandiso chekuchinja, ita shuwa kuti zvikamu zvinofamba zvemashini zvakaiswa mafuta zvakakwana kudzivirira jam kana kusashanda.

- Gearboxes: Magearboxes, kana aripo mumuchina wako, anogona kuda kuzorwa panguva dzakatarwa kuchengetedza kushanda zvakanaka uye kuderedza kusakara.

- Ball Screws: Bhora screws zvinhu zvakakosha muCNC michina. Kuzora kwakaringana kwebhora screws uye izvo zvinosanganisirwa zvikamu zvakakosha pakugadzirisa kwakaringana uye kufamba.

- Pombi Inotonhorera: Kana muchina wako ukashandisa inotonhodza sisitimu, ita shuwa kuti pombi yakanyatsoiswa mafuta uye kuti chinotonhodza chakachena uye chisina zvinosvibisa.

- Axis Motors: Zvichienderana nerudzi rwemotor dzinoshandiswa pakufamba kweaxis (semuenzaniso, stepper kana servo), tevera kurudziro yemugadziri wekuzora kana kugadzirisa.

- Zvisimbiso uye Gaskets: Ongorora uye kutsiva zvakasakara kana kukuvara zvisimbiso uye gaskets sezvinodiwa kudzivirira lubricant kuvuza uye kusvibiswa.

c. Maintenance Purogiramu

Kugadzira hurongwa hwekugadzirisa nguva dzose kwakakosha kuti uchengetedze muchina wako weCNC uri muchimiro chakanyanya. Heano matanho ekugadzira chirongwa chekugadzirisa:Danho 1: Manongedzo evagadziri

Tarisa zvinyorwa zvemugadziri uye kurudziro yenguva dzekugadzirisa, marudzi ekuzora, uye maitiro chaiwo.Danho 2: Kuchengetedza Zuva Nezuva

Shandisa mazuva ese ekugadzirisa maitirwo anosanganisira mabasa akaita sekuchenesa marara, kutarisa zvisungo zvakasununguka, uye kuongorora mazinga ekutonhodza. Aya mabasa anobatsira kudzivirira nyaya diki kubva mukukwira.Danho 3: Kwevhiki nevhiki kana Mwedzi Maintenance

Ronga mamwe mabasa akadzama ekugadzirisa pavhiki kana pamwedzi, zvichienderana nekushandiswa kwemuchina wako. Izvi zvinogona kusanganisira kucheneswa kwakakwana, kuisa mafuta, uye kuongororwa kwezvinhu zvakakosha.Danho rechina: Kugadziriswa kweKota kana Semi-Pagore

Ita mamwe mabasa akawandisa ekugadzirisa, akadai sekutarisa nekugadzirisa kurongeka, kuongorora kubatanidzwa kwemagetsi, uye kutsiva dzakasakara kana dzakakuvadzwa.Danho 5: Kuchengeta Kwegore

Pagore, funga nezve kuongororwa kwakazara nenyanzvi kana mainjiniya ane hunyanzvi. Izvi zvinofanirwa kusanganisira kutenderera kwakazara kwekuzora, macheki ekugadzirisa, uye chero inodiwa kugadzirisa kana kutsiva.Danho rechina: Zvinyorwa

Chengetedza marekodhi akadzama ezvese mabasa ekugadzirisa, kusanganisira misi, mabasa akaitwa, uye chero nyaya dzakaonekwa. Mapepa aya akakosha pakuronda nhoroondo yemuchina uye kuronga kugadzirisa ramangwana.Nhanho 7: Kudzidziswa

Ita shuwa kuti vashandi vane basa rekuchengetedza vakadzidziswa zvakaringana uye vanokwanisa kuwana maturusi anodiwa uye zviwanikwa. Kugara uchizora uye kugadzirisa kwakakosha pakuwedzera hupenyu uye kuita kweCNC muchina wako. Nekutevera yakanyatsogadziriswa hurongwa hwekugadzirisa uye kugadzirisa mapoinzi ekuzora, unogona kudzivirira kupera nguva isati yakwana uye ive nechokwadi chekuti muchina wako unoramba uchigadzira echokwadi uye emhando yepamusoro yekushanda. Muchitsauko chinotevera, tichakurukura nzira dzekuchengetedza uye nhungamiro yekushandisa yako CNC muchina.Chitsauko 8: Maitiro ekuchengetedza eCNC Machines

Kuchengetedzeka kwakakosha zvakanyanya kana uchishanda neCNC michina. Muchitsauko chino, tichaongorora nzira dzakakosha dzekuchengetedza uye nhungamiro dzekushandisa michina yeCNC, kusanganisira kuchengetedza kwemuchina weCNC, nzira dzekumisikidza, uye kushandiswa kwemidziyo yekuzvidzivirira (PPE).a. CNC Machine Kuchengetedza

- Kurovedza: Ita shuwa kuti vese vashandi vanoshanda kana kushanda vakatenderedza CNC michina vawana yakazara kuchengetedza kudzidziswa. Izvi zvinofanirwa kusanganisira kudzidziswa kwakanangana nemuchina, nzira dzakachengeteka dzekushandisa, uye kuzivikanwa kwenjodzi.

- Machine Guards: Chengetedza ese ekuchengetedza emuchina uye ekuchengetedza anokiya munzvimbo uye achishanda nemazvo. Aya maficha ekuchengetedza akagadzirirwa kuchengetedza vashandisi kubva kune zvinofamba zvikamu uye njodzi dzinogona kuitika.

- Safety Labels: Ita shuwa kuti mavara ekuchengetedza uye zviratidzo zveyambiro zvinoratidzwa pamushini. Aya mavara anopa ruzivo rwakakosha pamusoro penjodzi dzinogona kuitika uye kuchengetedzwa kwedziviriro.

- Emergency Stop: Jairira vashandisi nenzvimbo uye kushandisa bhatani rekumisa emergency. Ita shuwa kuti inowanikwa nyore nyore kana paine emergency.

- Bvisa Nzvimbo Yekushanda: Chengetedza nzvimbo yekushanda isina kuzara yakatenderedza CNC muchina. Bvisa chero zvishandiso zvisina basa, zvinhu, kana marara anogona kuunza njodzi yekugumburwa kana kukanganisa kushanda kwemuchina.

- Machine Lockout/Tagout (LOTO): Shandisa lockout / tagout maitiro ekubvisa-simba uye kuchengetedza muchina usati waita kugadzirisa kana kugadzirisa. Zvishandiso zvekuvhara zvinodzivirira kutangwa kwemuchina netsaona.

- Spindle uye Tool Chengetedzo: Bata maturusi ekucheka uye maturusi shanduko nekungwarira. Ita shuwa kuti maturusi akachengetedzwa nemazvo mumidziyo uye kuti shanduko yezvishandiso inoitwa zvichitevera nzira dzakachengeteka.

- Material Handling: Shandisa midziyo yekusimudza yakakodzera uye matekiniki paunenge uchibata zvinhu zvinorema kana maworkpiece. Dzivisa kuremedza huremu hwemuchina.

- Kuchengetedza Kwemoto: Chengeta zvekudzimisa moto uye ma detectors eutsi pedyo. Gadzira uye taura zvirevo zvekuchengetedza moto, kusanganisira nzvimbo yekubuda kwemoto uye nzira dzekubuda.

b. Emergency Shutdown Procedus

- Emergency Stop Button: Muchiitiko che emergency kana kana kudzima nekukasira kuchidikanwa, tinya bhatani rekumisa emergency. Bhatani iri rinowanzova hombe, dzvuku, uye rinowanikwa zviri nyore.

- Stop All Motion: Bhatani rekumisa emergency rinofanirwa kumisa mafambiro ese emuchina uye kuvhara simba kumushini. Ita shuwa kuti muchina unosvika pakumira zvachose.

- Kukiya/Tagout: Mushure mekushandisa bhatani rekumira nechimbichimbi, tevera nzira dzekuvhara / tagout kuchengetedza muchina uye kudzivirira kutanga netsaona.

- Zivisai Vakuru: Kana njodzi kana mamiriro ezvinhu ane ngozi akaitika, taura nevakuru vakakodzera, sevashandi vekugadzirisa kana vatariri, kuti vagadzirise nyaya yacho uye ive nechokwadi chokuti muchina wacho wakachengeteka kuti ushande zvakare.

c. Zvishandiso Zvekuzvidzivirira Pamunhu (PPE)

- Magirazi Ekuchengetedza: Vashandi nevashandi vari padhuze nemuchina weCNC vanofanirwa kupfeka magirazi ekuchengetedza ane akakodzera kupikisa kudzivirira maziso avo kubva kumarara anobhururuka.

- Kudzivirira Kunzwa: Muzvitoro zvemichina ine ruzha, zvinodzivirira kunzwa, zvakaita sezvivhariso munzeve kana zvinosunga nzeve, zvinofanira kupfekwa kudzivirira kukuvadzwa kwekunzwa.

- Magorovhosi Chipfeko: Pakubata zvinhu kana kuita mabasa ekugadzirisa, pfeka magirovhosi akakodzera basa racho. Ita shuwa kuti magirovhosi haaise njodzi pedyo neanofamba muchina zvikamu.

- Kudzivirirwa Pakufema: If machine zvinhus kugadzira huruva kana utsi, shandisa midziyo yekudzivirira yekufema, senge masks eguruva kana zvinofema, kuchengetedza njodzi yekufemba.

- Safety Shoes: Pfeka bhutsu dzakasimba dzekuchengetedza kana bhutsu dzine slip-resistant soles kudzivirira kubva mukukuvadzwa kwetsoka uye kuve nechokwadi chekudhonza kwakanaka munzvimbo yebasa.

- Zvipfeko zvinodzivirira: Zvichienderana nemaitiro ekugadzira uye zvinhu zvinoshandiswa, pfeka zvipfeko zvekudzivirira zvakakodzera, semaapuroni kana mavhavha akazara.

- Safe Helmets: Munharaunda umo zvinhu zvinodonha zvine njodzi, pfeka helmeti dzekuchengetedza kana ngowani dzakaoma kudzivirira musoro.

- Face Shields: Pamabasa anosanganisira njodzi dzinogona kuitika kumeso, sekupuruzira zvinotonhorera kana machipisi, shandisa zvivharo zvechiso mukuwedzera kune magirazi ekuchengetedza.

Chitsauko 9: Kugadzirisa Matambudziko Anowanzo Kuiswa

Muchitsauko chino, tichaongorora matambudziko akajairika anogona kumuka panguva yekuiswa kweCNC michina uye nekupa mhinduro dzekugadzirisa idzi nyaya. Pamusoro pezvo, isu tichakurukura nzira dzekugadzirisa matambudziko dzinogona kukubatsira kuona nekugadzirisa matambudziko nemazvo.a. Matambudziko Anowanikwa uye Mhinduro

-

Matambudziko eMagetsi:

- Problem: Muchina weCNC haubatike.

- Solution: Tarisa panobva magetsi, kubatanidza magetsi, uye fuse. Ita shuwa kuti bhatani rekumisa emergency raburitswa.

-

Mechanical Misalignment:

- Problem: Muchina uyu unoburitsa zvisina kuchekwa kana zviyero zveworkpiece.

- Solution: Gadzirisa uye kuyera muchina. Tarisa kune zvakasara zvikamu kana magwagwa akasakara uye wotsiva sezvinodiwa.

-

Tool Chatter kana Vibration:

- Problem: Muchina uyu unoburitsa mavibrations kana chishandiso chatter, zvichikanganisa kupera kwepamusoro.

- Solution: Tarisa chibatiso cheturusi uye spindle collet yekugara kwakaringana. Rongedza kucheka maparameter uye toolpath marongero.

-

Mhosho dzeKutaurirana:

- Problem: Iyo CNC controller haigone kutaurirana nekombuta kana CAD/CAM software.

- Solution: Simbisa tambo dzekubatanidza, baud mitengo, uye zvigadziriso pamushini nemukombuta. Ita shuwa chaiyo software uye mutyairi kumisikidzwa.

-

Kuputsika kweTool:

- Problem: Zvishandiso zvinowanzoputsika panguva yekugadzira.

- Solution: Tarisa kurongeka kweturusi, mamiriro emudziyo, uye spindle runout. Gadzirisa mafeed uye kumhanya zvichibva pane zvekushandisa uye workpiece.

-

Matambudziko eKutonhodza kana Kuzora:

- Problem: Kusakwana kana kusaenzana kunotonhorera/kuzora kuyerera.

- Solution: Tarisa inotonhorera uye yekuzora sisitimu zvikamu, senge pombi, hoses, uye nozzles. Chenesa kana kutsiva mafirita uye chengetedza mazinga akakodzera emvura.

-

Zvikanganiso zveSoftware:

- Problem: Iyo control software inoratidza mameseji ekukanganisa kana maitiro asingatarisirwe.

- Solution: Ongorora mameseji ekukanganisa uye bvunza zvinyorwa zvesoftware. Tarisa nyaya dzekuenderana uye gadziridza software kana firmware sezvinodiwa.

b. Troubleshooting Techniques

- Maitiro Akarongeka: Paunenge uchigadzirisa nyaya, tora nzira yakarongeka nekuona uye kupatsanura panobva dambudziko. Tanga nekutarisa kwakaringana uye tsvaga zvishoma nezvishoma zvikonzero zvakaoma.

- Zvinyorwa: Tarisa kumabhuku emuchina, zvinyorwa, uye zvakapihwa mugadziri-zviwanikwa zvekugadzirisa matambudziko kutungamira uye kukanganisa kodhi dudziro.

- Kuyera uye Kuedza: Shandisa zviridzwa zvekuyeresa senge dial zviratidzo, calipers, uye micrometer kuongorora kurongeka, hukuru, uye chishandiso runout. Ita bvunzo dzekucheka kuti uone chokwadi chekugadzira.

- Visual Inspection: Ita kunyatsoongorora kwekuona kwemuchina, uchitarisa zvisungo zvakasununguka, zvakakanganisika zvikamu, kana zviratidzo zvinoonekwa zvekupfeka.

- Zvinyorwa uye zvinyorwa: Ongorora matanda ekugadzirisa, matanda ekukanganisa, uye marekodhi ezvinyorwa zvekare kuti uone matambudziko anoramba achidzokororwa kana mapatani.

- Bvunza Nyanzvi: Kana ukasangana nematambudziko akaoma kana anoenderera mberi, bvunza nyanzvi, senge mugadziri wetsigiro yehunyanzvi, matekinoroji ane hunyanzvi, kana machini ane ruzivo anogona kunge asangana nematambudziko akafanana.

- Safe Troubleshooting: Nguva dzose chengetedza kuchengeteka panguva yekugadzirisa dambudziko. Tevedza maitiro ekuvhara / tagout, dzima muchina, uye shandisa zvakakodzera zvekuzvidzivirira nazvo (PPE).

- Zvinyorwa: Chengetedza marekodhi akadzama ezviitiko zvekugadzirisa matambudziko, kusanganisira matanho akatorwa, zvakaonekwa, uye zvigadziriso zvakashandiswa. Aya marekodhi anogona kuve akakosha kune ramangwana.

- Kuenderera Kudzidza: Kurudzirai tsika yekuenderera mberi nekudzidza nekugovana ruzivo pakati pechikwata chako. Chiitiko chinowanikwa kubva mukugadzirisa matambudziko chinogona kutungamirira kukuvandudza maitiro ekudzivirira kuchengetedza.

Chitsauko 10: Macheki ekupedzisira uye Kuedzwa

Muchitsauko chino chekupedzisa, tichakurukura matanho akakosha ekumhanyisa zvirongwa zvebvunzo, kuve nechokwadi chechokwadi, uye kunyatsogadzirisa kuisirwa kwemuchina wako weCNC kuti uwane kuita kwakakwana.a. Running Test Programs

- Kusarudzwa Kwezvirongwa Zvekuedza: Gadzirira bvunzo zvirongwa zvinosanganisira huwandu hwemachining mashandiro achaita muchina wako weCNC. Aya mapurogiramu anofanirwa kusanganisira mafambiro ekutanga, shanduko yekushandisa, uye akasiyana ekucheka mamiriro.

- Tool uye Workpiece Setup: Isa maturusi akakodzera uye chengetedza yekuyedza workpiece pamuchina wekushanda kana gadziriso. Ita shuwa kuti maturusi ekubvisa uye maoffsets ebasa akarongwa nemazvo.

- Dry Run: Pakutanga, ita yakaoma kumhanya pasina chero kucheka. Izvi zvinokutendera kuti utarise mafambiro emuchina, shanduko yechishandiso, uye kuyerera kwehurongwa hwese kune chero kukanganisa kana maitiro asingatarisirwe.

- Kusarudzwa Kwezvinhu: Sarudza bvunzo zvinhu zvakafanana neiyo yaunoronga kushandisa kune yako chaiyo machining mapurojekiti. Izvi zvinoita kuti mhedzisiro yebvunzo inyatso kutevedzera mamiriro epasirese.

- Kucheka Miedzo: Ita zvirongwa zvekuedza nekucheka mashandiro. Tarisa mashandiro emuchina, uchinyatso tarisisa kurongeka kweturusi, kumhanya kwespindle, uye mitengo yekudyisa.

b. Kuva nechokwadi Nekururama

- Kuyera uye Kuongorora: Mushure mekuita zvigadziriso zvebvunzo, pima hukuru uye kupera kwepamusoro kwezvishandiso zvebvunzo uchishandisa zviridzwa zvekuyeresa. Enzanisa mibairo kune yakatarwa dhizaini yakatarwa.

- Tool Inspection: Ongorora maturusi ekucheka kuti ane zviratidzo zvekupfekwa, senge akachekwa mipendero kana kupfeka kwakanyanyisa. Tsiva kana kurodzazve maturusi sezvinodiwa.

- Workpiece Inspection: Ongorora bvunzo workpiece kune chero hurema, pamusoro pekupedzisira nyaya, kana kutsauka kubva kune yaunoda geometry. Gadzirisa chero matambudziko akaonekwa panguva yekuongorora.

- Mhinduro uye Ongororo: Ongorora mhedzisiro yebvunzo kuti uone chero kupesana kana kutsauka kubva pane zvinotarisirwa zvabuda. Sarudza kana kugadzirisa kuchidikanwa kuti uvandudze huchokwadi.

c. Fine-Tuning

- Toolpath Optimization: Kana mhinduro dzebvunzo dzichiratidza kusarongeka kana matambudziko ekupera kwepamusoro, funga kugadzirisa nzira dzematurusi mune yako CAM software. Gadzirisa maturusi enzira, sarudzo yezvishandiso, uye kucheka kumhanya uye mafidhi sezvinodiwa.

- Machine Parameter Kugadziriswa: Ongorora zvinyorwa zvemuchina kuti unyatso gadzirisa ma paramita, sekumhanyisa, kudzikisira, uye muripo wekudzokera kumashure. Izvi zvinogadziriswa zvinogona kuwedzera kurongeka.

- Tool Offset Calibration: Recalibrate tool offsets kana zvichidiwa. Ita shuwa kuti muchina wacho unoripira kureba kwechishandiso uye dhayamita, kuderedza zvikanganiso mukugadzira.

- Work Offset Kururamisa: Tarisa uye ugadzirise zvigadziriso zvebasa kuti uve nechokwadi chekuti muchina unoisa chishandiso zvakanyatsoenderana neworkpiece. Zvikanganiso zvidiki mukugadzirisa basa zvinogona kutungamirira kune zvakakosha kusarurama.

- Kuedzazve: Mushure mekugadzirisa uye kugadzirisa zvakanaka, mhanyisa zvakare mapurogiramu ebvunzo kuti uone kuvandudzwa mukurongeka uye kupera kwepasi.

- Zvinyorwa: Nyora zviitiko zvese zvekugadzirisa zvakanaka, zvigadziriso, uye mibairo yebvunzo kuti ugozoishandisa mune ramangwana. Aya magwaro achave akakosha pakuchengetedza kuenderana mumabasa ako emuchina.

Chitsauko 11: Kudzidzisa uye Kukudziridzwa Kweunyanzvi

Muchitsauko chino, tichasimbisa kukosha kwekudzidziswa uye kuvandudza hunyanzvi kune vese vashandisi vemichina nevashandi vekuchengetedza. Kudzidziswa kwakaringana uye kusimudzira hunyanzvi kwakakosha pakuita kuti ive yakachengeteka uye inoshanda CNC muchina mashandiro, pamwe nekuchengetedza nemazvo nekugadzirisa midziyo.a. Operator Training

- Basic Machine Operation: Vashandi vanofanirwa kuwana kudzidziswa kwakadzama pamusoro pezvinhu zvakakosha zve CNC mashandiro emuchina, kusanganisira kutanga muchina, kudzima, kumba, uye kumhanya.

- Kunzwisisa G-makodhi uye M-makodhi: Vashandi vanofanirwa kuve nehunyanzvi mukuturikira nekugadzirisa maG-code neM-code, ayo anodzora mafambiro nemashandiro emuchina.

- Tool Handling: Maitiro ekubata maturusi akakodzera, anosanganisira shanduko yezvishandiso, zvigadziriso zvematurusi, uye chiyero cheturusi, zvakakosha kudzivirira tsaona uye kuve nechokwadi chekuti machining akarurama.

- Workpiece Setup: Kudzidzira kunofanirwa kuvhara kuseta kweseti, kusanganisira kubata basa, kurodha zvinhu, uye kuchengetedza maworkpiece kumuchina wekushanda kana gadziriso.

- Nzira dzekuchengetedza: Vashandi vanofanirwa kuve neruzivo rwakanyanya muCNC muchina kuchengetedza maitiro, emergency shutdown protocol, uye kushandiswa kwemidziyo yekuzvidzivirira (PPE).

- Dambudziko rekutanga: Hunyanzvi hwekugadzirisa matambudziko, hwakadai sekuziva zvinhu zvakajairika uye kuziva nguva yekutsvaga rubatsiro, zvinogona kubatsira vashandisi kugadzirisa matambudziko madiki nekukasika.

- Quality Control: Kudzidziswa muhutongi hwemhando uye hunyanzvi hwekuongorora kwakakosha kuti uve nechokwadi chekuti mapeji ebasa anopedzwa anosangana nekushivirira kwakatsanangurwa uye pekupedzisira zvinodiwa.

- Simulation uye Dzidzira: Vashandi vanofanirwa kuve nemikana yekudzidzira-maoko uye maekisesaizi ekusimudzira hunyanzvi hwavo uye kuvaka kusatya mukushanda muchina weCNC.

b. Maintenance Training

- Preventive Maintenance: Vashandi vekuchengetedza vanofanirwa kuwana kudzidziswa pamusoro pemaitiro ekudzivirira ekuchengetedza ekuita zvakananga kumuchina weCNC, anosanganisira mafuta, kuchenesa, uye maitiro ekuongorora.

- Machine Components: Kunzwisisa kwakadzama kwezvikamu zvemuchina, zvinosanganisira mota, masensa, madhiraivha, uye masisitimu emagetsi, zvakakosha kuti vashandi vekuchengetedza vaongorore uye vagadzirise nyaya nemazvo.

- Matanho ekugadzirisa matambudziko: Unyanzvi hwepamberi hwekupedza matambudziko, hwakadai sekuongorora matambudziko emagetsi, emuchina, uye anechekuita nesoftware, akakosha pakudzikisa nguva yekudzikira uye nekugonesa kuita kwemuchina.

- Lubrication uye Fluid Management: Kuziva kwakaringana kwemapoinzi ekuzora, mhando dzemvura, uye kusefa masisitimu kwakakosha kuchengetedza kutendeseka kwemuchina.

- Electrical Systems: Vashandi vekuchengetedza vanofanirwa kudzidziswa mumasisitimu emagetsi, kusanganisira kunzwisisa madhayagiramu ewaya, mapuroteni ekuchengetedza magetsi, uye kutsiviwa kwezvikamu zvemagetsi.

- Advanced Calibration: Kudzidziswa pamaitiro epamberi ekugadzirisa, senge laser alignment uye spindle runout kuyerwa, kunogona kuvandudza iko kurongeka kweCNC muchina.

- Software Kugadziridza: Kuzivana nesoftware zvigadziriso uye firmware upgrades kwakakosha kuchengetedza software yekudzora uye muchina firmware kusvika parizvino.

c. Skill Enhancement

- Kuenderera mberi nekudzidza: Kurudzirai tsika yekuenderera mberi nekudzidza pakati pevashandisi nevashandi vekuchengetedza. Izvi zvinogona kusanganisira kuenda kumashopu, masemina, uye makosi epamhepo ane chekuita neCNC tekinoroji.

- Skill Evaluation: Nguva nenguva ongorora hunyanzvi uye ruzivo rwevashandisi nevashandi vekuchengetedza kuti vaone nzvimbo dzekuvandudza nekudzidziswa kwakanangwa.

- Cross-Training: Funga nezvevashandisi vekudzidzira mumabasa ekugadzirisa ekutanga uye zvakasiyana. Izvi zvinogona kuwedzera kunzwisisa kwese uye kubatana mukati mechikwata.

- Mentorship: Ita zvirongwa zvekupa mazano apo vashandi vane ruzivo vanogona kupa hutungamiri uye kugovera ruzivo rwavo kune nhengo dzechikwata dzisina ruzivo.

- Kugadzirisa Matambudziko: Kurudzira vashandi kuti vashingaire kuita maekisesaizi ekugadzirisa matambudziko uye nekuongorora chikonzero chemudzi, vachisimudzira tsika yekukurumidza kugadzirisa matambudziko.

- Feedback Loop: Gadzirai loop yemhinduro apo vashandisi nevashandi vekugadzirisa vanogona kutaurirana nyaya, kugovana ruzivo, uye kupa mazano ekuvandudzwa kwemashandiro emuchina nekugadzirisa.

mhedziso

Mugwaro rino rakazara, takaongorora maitiro akaomarara ekumisikidza muchina weCNC, tichivhara nyaya dzakasiyana siyana kuti ive nechokwadi chekuti muchina wako weCNC waunganidzwa, wakaiswa, uye unoshanda nemazvo uye zvakachengeteka. Ngatipei muchidimbu mapoinzi akakosha, tisimbise kukosha kweiyo CNC yekumisikidza muchina, uye titarise kumberi kune ramangwana reCNC tekinoroji.a. Pfupiso Yepfungwa Dzakakosha

Mugwaro rose iri, takafukidza zvinotevera zvakakosha pfungwa:- Kunzwisisa CNC Machina: Takatanga nekukurukura kuti CNC michina chii, marudzi akasiyana-siyana aripo, uye ayo akakosha zvikamu.

- Pre-Instalation Gadziriro: Takasimbisa kukosha kwekugadzirira nzvimbo yekushanda, kusangana nesimba uye zvinodiwa nemagetsi, uye kushandisa matanho ekuchengetedza tisati taiswa.

- Kubatanidza iyo CNC Machine: Matanho ane udzame akagoverwa kubhedhenura, kuronga zvinhu, kubatanidza furemu yomuchina, kubatanidza mota nemadhiraivha, kuisa control panel, uye kutarisira tambo.

- Kuenzanisa uye kuenzanisa: Takakurukura kukosha kwekugadzirisa uye kuenzana, maturusi anodiwa, uye nhanho-ne-nhanho maitiro ekuwana kurongeka kwakanyatso.

- Electrical Wiring: Kunzwisisa masisitimu emagetsi, wiring yemuchina weCNC, uye kuomerera kune zvekuchengetedza panguva yebasa remagetsi zvakavharwa.

- Kuisa iyo Control Software: Kuiswa kwekutonga software, calibration, uye maitiro ekuyedza zvakakurukurwa kuti ive nechokwadi chekuti muchina weCNC unoshanda nemazvo.

- Lubrication uye Maintenance: Kukosha kwekuzora uye kugadzirisa kwehupenyu hurefu hwemuchina uye kuita kwakaratidzwa, kusanganisira nzvimbo dzekuzora uye zvirongwa zvekugadzirisa.

- Nzira dzekuchengetedza: Matanho ekuchengetedza, maprotocol ekuvharirwa kwechimbichimbi, uye kushandiswa kwemidziyo yekudzivirira (PPE) kwakagadziriswa kugadzira nzvimbo yekushanda yakachengeteka.

- Kugadzirisa Matambudziko Anowanzo Kuiswa: Matambudziko akajairika uye nzira dzekugadzirisa matambudziko dzakapihwa kubatsira kuona nekugadzirisa nyaya nemazvo.

- Kuongorora Kwekupedzisira uye Kuedzwa: Kumhanyisa bvunzo zvirongwa, kuve nechokwadi, uye kunyatsogadzirisa muchina zvakakurukurwa kuti uwane kuita kwakaringana.

- Kudzidzira uye Kuvandudza Unyanzvi: Kukosha kwekudzidziswa kwevashandi nekuchengetedza vashandi, pamwe nekuenderera mberi kwekusimudzira hunyanzvi, kwakasimbiswa.

b. Iko Kukosha Kweiyo Yakakodzera CNC Machine Kuisa

Yakakodzera CNC yekumisikidzwa kwemuchina ndiyo hwaro pakavakirwa budiriro yekugadzira machining. Izvo zvakakosha kune zvikonzero zvinotevera:- Kutendeseka: Muchina wakamisikidzwa zvakanaka weCNC unokwanisa kuburitsa zvikamu zvakaringana uye zvakanyatsoita, kuderedza zvimedu uye kushandazve.

- Kudzivirirwa: Kuiswa kunoteera kukuchengetedza zviyero uye maitiro kunovimbisa kugara zvakanaka kwevashandisi vemuchina uye vashandi vekugadzirisa.

- Nguva refu: Kuisirwa kwakaringana uye kugaro gadzirisa kunowedzera hupenyu hwe CNC muchina wako, kuchengetedza mari yako.

- Kushanda: Muchina wakaiswa zvakanaka unoshanda nemazvo, uchideredza nguva yekudzikira uye nekuwedzera chibereko.

- Quality: Hunhu hwekugadzika hunobata zvakananga kunaka kwezvikamu zvemichina, zvinotungamira kune vatengi vanogutsikana uye mukurumbira wakavandudzwa.

c. Kutarira Mberi

Sezvo tekinoroji ichiramba ichifambira mberi, CNC michina ichave yakanyanya kugona uye inoshanda zvakasiyana. Izvo zvakakosha kuti ugare uchiziva nezvezvichangobva kuitika, software inogadziridza, uye akanakisa maitiro muCNC machining. Pamusoro pezvo, sezvo tekinoroji yeCNC inowedzera kuwanikwa, maindasitiri mazhinji uye mabhizinesi anogona kubatsirwa kubva kune zvakanakira. Mukupedzisa, CNC yekuisa muchina inzira yakaoma asi ine mubairo. Nekutevera nhungamiro uye akanakisa maitiro akatsanangurwa mugwaro iri, unogona kuseta nhanho yeakabudirira CNC machining oparesheni. Rangarira kuti kuramba uchidzidza, kudzidziswa, uye kuenderera mberi nekugadzirisa ndizvo zvakakosha pakuchengetedza nekuvandudza mashandiro emichina yako yeCNC paunenge uchitarisira ramangwana rakazadzwa nemikana munyika yekugadzira chaiyo.

Our Services

- 5 Sekaiichi machine

- Cnc Kugaya

- Cnc Kutendeuka

- Machining Maindasitiri

- Machining Maitiro

- Surface Kurapa

- Simbi yekushandisa

- Mapepa epurasitiki

- Upfu hweMetallurgy Mould

- Die Casting

- Zvikamu Garari

Case Studies

- Auto Metal Zvikamu

- Machinery Parts

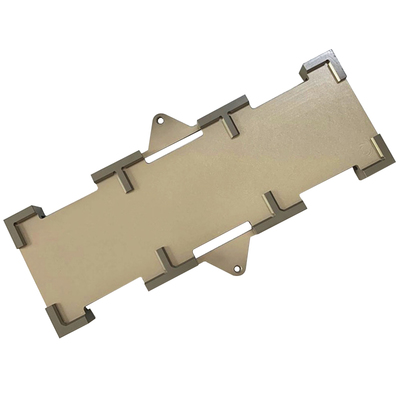

- Akatungamira Heatsink

- Kuvaka Zvikamu

- Sravana Sameeralu Serial XNUMXth Mobile Parts

- Zvikamu Zvekurapa

- Zvikamu Zvemagetsi

- Zvichienderana machine

- Bicycle Parts

Chinyorwa Chinyorwa

- Aluminum machine

- Titanium Kubata

- Stainless Simbi machine

- Mhangura machine

- Brass machine

- Super chiwanikwa machine

- Peek Kugadzira

- UHMW machine

- Sanganisa Machining

- PA6 Kugadzira

- PPS machine

- Teflon Kugadzira

- Inconel machine

- Danho Simbi machine

- Zvimwe Zvinyorwa

Zvikamu Garari