Nhungamiro Yakazara kune Akasiyana Marudzi eLathe Yekucheka Zvishandiso zveKutendeuka, Kufinha, Kutarisana, Chamfering, uye Zvimwe Mashandiro.

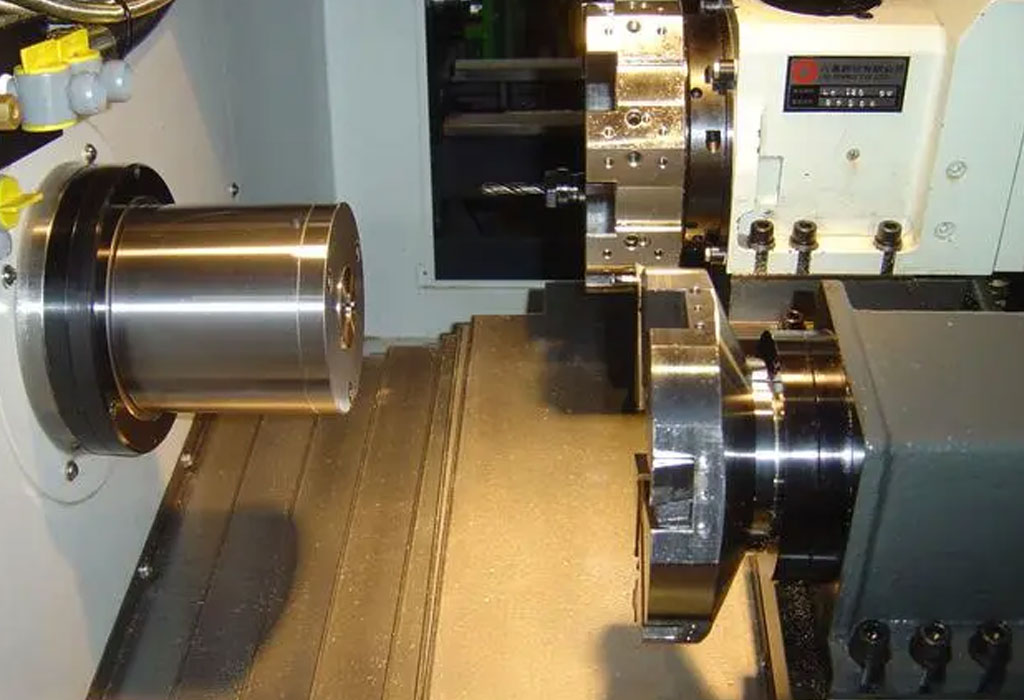

Lathe michina yanga iri chikamu chakakosha chekugadzira kwemazana emakore, ichigonesa kugadzirwa kwechaiyo uye yakaoma kunzwisisa cylindrical zvikamu. Chimwe chezvinhu zvakakosha zvinotaridza kubudirira kwekuita lathe kusarudzwa uye kushandiswa kwemidziyo yekucheka. Zvishandiso izvi zvinouya mumhando dzakasiyana siyana, saizi, uye zviwanikwa, chimwe nechimwe chakagadzirirwa mamwe mabasa akadai sekutendeuka, kufinha, kutarisana, kukwezva, nezvimwe. Mugwaro rino rakazara, isu tichaongorora nyika yematurusi ekucheka maturusi, tichiongorora mumhando dzawo, hunhu, mashandisirwo, uye akanakisa maitiro ezvakanyanya machining mhedzisiro. Kunyangwe iwe uri mudzidzi ari kutsvaga kudzidza izvo zvekutanga kana mugadziri ane ruzivo ari kutsvaga kuwedzera ruzivo rwako, chinyorwa ichi chine chinangwa chekupa ruzivo rwakakosha munyika yakaoma kunzwisisa yekucheka lathe maturusi.

Chikamu 1: Kushandura Zvishandiso

Kushandura mashandiro ibwe rekona re lathe machining, richitamba basa rakakosha mukugadzira cylindrical zvinhu zvine humbowo uye nemazvo. Mabasa aya anosanganisira kubvisa zvinhu kubva pachishandiso nekuchitenderedza uchipokana nechishandiso chekucheka, chinowanzoiswa pachirungi. Kutendeuka kwakakosha mumaindasitiri akasiyana siyana, anosanganisira emotokari, aerospace, kugadzira, nezvimwe, zvichiita kuti zvive zvakakosha pakunzwisisa maturusi anoshandiswa mukuita. Maturusi ekushandura, mumamiriro ekugadzira lathe machining, ndiwo midziyo yekucheka inoumba uye inonatsa maworkpiece panguva yekushandura mashandiro. Ivo vanouya mumhando dzakasiyana-siyana dzemafomu, zviwanikwa, uye geometries kuti ikwane zvakasiyana zvinodiwa uye zvinhu. Kunzwisisa kukosha kwekushandura maturusi uye marudzi avo akasiyana-siyana kwakakosha kuti uwane zvinodikanwa zvemuchina.1.2. Mhando dzeKushandura Zvishandiso

Maturusi ekushandura anowanikwa mumhando dzinoverengeka, imwe neimwe yakagadzirirwa kuenderana nezvinodiwa zvemuchina. Ngationgororei mamwe mapoka akafanana:- 1.2.1. High-Speed Steel (HSS) Zvishandiso: High-Speed Steel (HSS) maturusi anga ari akanyanya mukugadzira kwemakumi emakore. Vane mukurumbira wekuita zvakasiyana-siyana, sezvo vachigona kucheka zvinhu zvakasiyana-siyana, zvinosanganisira simbi ine ferrous uye isiri-ferrous, mapurasitiki, uye kunyange huni. Zvishandiso zveHSS zvinogona kuchengetedza kuoma kwavo uye kugona kucheka pane tembiricha dzakakwirira, zvichiita kuti dzive dzakakodzera kutendeuka-kumhanya.

- 1.2.2. Carbide Insert Zvishandiso: Carbide yekuisa maturusi awana mukurumbira nekuda kwekuoma kwavo kwakasarudzika uye kuramba kupfeka. Aya maturusi anoratidza inotsiviwa carbide inoisa iyo inopa yakapinza yekucheka mipendero uye yakawedzerwa hupenyu hwematurusi. Iwo akanakisa kushandura zvinhu zvakaoma sesimbi isina tsvina, machining cast iron, uye exotic alloys. Carbide kuisa maturusi anowanzo shandiswa mune ese ari maviri roughing uye kupedza mashandiro.

- 1.2.3. Dhaimondi Zvishandiso: Dhaimondi rekushandura maturusi anoshandisa synthetic diamond sechinhu chekucheka. Madhaimondi anozivikanwa nekuoma kwawo, izvo zvinobvumira nemazvo machine yemidziyo yakaoma zvakanyanya senge ceramics negirazi. Maturusi edhaimani akanakira maapplication anoda epamusoro pepamusoro pekupedzisira uye dimensional kurongeka.

- 1.2.4. Cermet Zvishandiso: Zvishandiso zveCermet isanganiswa yekeramics nesimbi, ichipa chiyero pakati pekuoma uye kuoma. Ivo vakanyatsokodzera machining epamusoro-tembiricha alloys uye simbi dzakaomeswa. Cermet zvishandiso zvinonyanya kumhanyisa-kumhanya machining application, kwavanogona kutsungirira tembiricha yakakwira uye kuchengetedza kuita kwavo kwekucheka.

- 1.2.5. Cubic Boron Nitride (CBN) Zvishandiso:Cubic Boron Nitride (CBN) maturusi ari pakati peakanyanya kuoma maturusi ekucheka aripo, yechipiri chete kune diamond. Iwo akanakira kugadzira simbi dzakaomeswa uye superalloys. Zvishandiso zveCBN zvinopa kusarudzika kupfeka kuramba, zvichiita kuti ive yakakodzera kuenderera uye kukanganiswa kucheka muzvinhu zvinonetsa.

1.3. Kusarudza Right Turning Tool

Kusarudza chakakodzera chekushandura chishandiso isarudzo yakakosha inopesvedzera kubudirira kwechigadzirwa chemuchina. Hezvino zvinhu zvakakosha zvekufunga nezvazvo pakusarudza chishandiso chekushandura:- 1.3.1. Material Kuenderana: Iyo workpiece zvinhu chinhu chakakosha pakusarudza chishandiso. Zvishandiso zvakasiyana zvine kuoma kwakasiyana, abrasiveness, uye thermal conductivity. Ita shuwa kuti chishandiso chakasarudzwa chinoenderana neiyo workpiece zvinhu kudzivirira kupera nguva isati yakwana kana kutadza kwechishandiso.

- 1.3.2. Tool Geometry:Iyo geometry yechishandiso, kusanganisira chimiro chayo, kona yekona, uye angles yekubvisa, inokanganisa zvakanyanya kucheka mashandiro. Funga nezve izvo chaizvo zvinodikanwa zvekushandura, senge roughing kana kupedzisa, uye sarudza chishandiso chine geometry yakakodzera kuti ugone mhedzisiro.

1.4. Mazano eKubudirira Kutendeuka

Kuwana budiriro yekushandura mashandiro kunoda kutarisisa kune zvakadzama uye nemazvo. Heano mamwe matipi akakosha ekuwedzera kushanda kwekushandura maturusi:- 1.4.1. Yakakodzera Tool Setup uye Alignment: Ita shuwa kuti chishandiso chakachengetedzwa zvakachengeteka uye chakamisikidzwa nemazvo pane iyo lathe's tool post. Chero kusarongeka kunogona kukonzera kupera kwakashata kwepamusoro, kuwedzera kupfeka kwemidziyo, uye kuderedzwa kwechokwadi.

- 1.4.2. Machining Parameters uye Surface Pedzisa Kufunga: Rongedza kucheka maparamendi akadai sekucheka kumhanya, chiyero chekudya, uye kudzika kwekucheka zvinoenderana nebasa rekushandisa uye rudzi rwechishandiso. Nyatsodzora maparamendi aya kuti uwane inodiwa kupera kwepamusoro, kurongeka kwedimensional, uye chip evacuation.

Chikamu 2: Zvishandiso Zvinofinha

2.1. Nhanganyaya kune Boring Tools

Boring mashandiro anokosha kune machine kwachoes, ichibvumira kukwidziridzwa kana kukwenenzverwa kwemakomba aripo mumabasa ekushanda. Kunyangwe iri kugadzira makomba akaenzana mumabhuroki einjini kana kuwana kushivirira kwakasimba muzvikamu zvecylindrical, maturusi anofinha akakosha mumaindasitiri akasiyana. Muchikamu chino, tichaongorora nyika yezvishandiso zvinofinha zvinoshandiswa mukugadzira lathe. Zvishandiso zvinobhowa, sezvinoratidzwa nezita racho, zvakagadzirirwa kubereka maburi nehupamhi hwepamusoro. Zvinonyanya kubatsira kana nzira dzekuchera dzakajairika dzisina kukwana kana gomba richida kunyatsoenderana nechinhu chiripo. Kunzwisisa kukosha kwemabasa anofinha uye kuwana nzwisiso mumhando dzezvishandiso zvinofinha zviripo zvakakosha kuti uwane mibairo chaiyo yekugadzira.2.2. Mhando dzeZvishandiso Zvinobhowa

Zvishandiso zvinobhowa zvinosanganisira huwandu hwezviridzwa zvine hunyanzvi, imwe neimwe yakagadzirirwa mashandisirwo chaiwo. Ngationgororei mamwe mapoka akajairwa ezvishandiso zvinofinha:- 2.2.1. Mabhawa anobhowa: Mabhawa anobhowa anochinja-chinja uye anoshandiswa zvakanyanya mukugadzira lathe machining. Aya maturusi akatetepa, akarebesa anokwanisa kusvika pakadzika mukati mezvishandiso zvekuboora maburi nemazvo. Mabhawa anobhowa anogona kugarisa akasiyana marudzi ekuisa, achiaita akakodzera kune ese ari maviri roughing uye yekupedzisa mashandiro.

- 2.2.2. Boring Heads: Misoro inobhowa inopa kuchinjika kukuru maererano nekugadzirisa dhayamita yechibhorani. Iwo anosanganisira muviri unogara mudziyo wekucheka uye nzira yekuwedzera kugadzirisa. Izvi zvinobvumira machinists kunyatso kudzora saizi yebhore panguva yekugadzira machining.

- 2.2.3. Kurova uye Kupedza Zvishandiso Zvinofinha Maturusi anofinha anofinha akagadzirirwa kubviswa kwezvinhu pamitengo yepamusoro yekudyisa, nepo kupedzisa maturusi anofinha achipa iko kudiwa uye kupera kwepamusoro. Kushandisa musanganiswa wezvishandiso izvi kunobvumira kushanda kwakanyatsoita uye kwakaringana kunofinha.

2.3. Kusarudza Right Boring Tool

Kusarudza chakakodzera chinofinha chishandiso kwakakosha kuti uwane zvakabudirira machining mhedzisiro. Zvinhu zvakati wandei zvinokonzeresa kusarudzwa kwechishandiso chinofinha:2.3.1. Zvinhu Zvinokurudzira Boring Tool Sarudzo

- Workpiece Material: Izvo zvinhu zviri kugadzirwa zvinokanganisa zvakanyanya kusarudzwa kwezvishandiso. Zvishandiso zvakaomesesa zvingada hunyanzvi hwekushandisa necarbide inoiswa, nepo zvinyoro zvinyoro zvinogona kugadzirwa zvine mutsindo nematurusi e-high-speed steel (HSS).

- Gomba Saizi uye Kushivirira: Iyo inodiwa bhomba saizi uye kusimba kwekushivirira kunoraira kusarudzwa kwechishandiso chinofinha. Misoro inobhowa inowanzofarirwa kana kudzora chaiko pamusoro pedhayamita yakabhoreka kuchidikanwa.

- Kudzika kweBore: Kudzika kwegomba kunopesvedzera sarudzo yechishandiso, sezvo mabhora akareba angangoda mabhawa anofinha ane kureba kusvika.

- Machining Conditions: Funga nezvenzvimbo yekugadzira, senge iri CNC lathe kana manual lathe, pamwe chete neiyo iripo yekucheka fluid uye inotonhorera masisitimu.

2.3.2. Material Removal Rates uye Tool Adjustments

Kugonesa mashandiro anofinha, zvakakosha kuseta iwo chaiwo ekucheka maparamita, anosanganisira kucheka kumhanya, chiyero chekudya, uye kudzika kwekucheka. Kugadziriswa kune aya ma parameter kunofanirwa kuitwa zvichibva pane workpiece zvinhu uye yakasarudzwa inofinha chishandiso. Kunyatso kuenzanisa mareti ekubvisa zvinhu nekugadzirisa maturusi kunoita kuti machining ashande pasina kukanganisa kurongeka.2.4. Maitiro Akanakisisa eKushanda Kubhowa

Kuwana chokwadi uye kuchengetedza kushivirira kwakasimba mumabasa anofinha kunoda kunyatsotarisisa maitiro akanakisa. Heano mamwe matipi akakosha:- 2.4.1. Tool Setup uye Workpiece Clamping: Ita shuwa kuti chishandiso chinobhowa chakaiswa zvakachengeteka uye chakabatana neworkpiece. Kugadzika kwechishandiso kwakaringana kunoderedza kudedera uye kunosimudzira kugadzikana kwekucheka. Chengetedza workpiece clamping yakakosha zvakaenzana kudzivirira kufamba panguva yekugadzira machining.

- 2.4.2. Kuwana Tight Tolerances uye Surface Finishes: Kuti uwane kushivirira kwakasimba, ita gadziriso dzekuwedzera kune inobhowa chishandiso uchitarisa saizi yebore nezviridzwa zvekuyeresa. Gara uchitarisa uye chengetedza kupinza kwekucheka kuti uve nechokwadi chekupedza kwemhando yepamusoro uye kurongeka kwedimensional.

Chikamu 3: Kutarisana Nezvishandiso

3.1. Nhanganyaya Yekutarisana Nezvishandiso

Kutarisana nekushanda mukugadzira lathe kwakakosha pakugadzira nzvimbo dzakati sandara uye dzakatsetseka pamagumo ecylindrical workpieces. Kungave kuri kukwidibira kumagumo a mugodhi kana kuve nechokwadi cheiyo chaiyo yekubatanidza nzvimbo yezvikamu, yakatarisana yakajairika uye yakakosha machining maitiro. Muchikamu chino, isu tichaongorora basa rekutarisana nekushanda uye kunyura munyika yekutarisana nemidziyo inoshandiswa mukugadzira lathe. Maturusi ekutarisana, sezvinoreva zita rawo, maturusi akasarudzika akagadzirirwa kuita mabasa akatarisana nemazvo. Vanogonesa machinist kubvisa zvinhu zvakaenzana kubva kumagumo echishandiso, zvichikonzera nzvimbo yakati sandara uye yakatsetseka. Kunzwisisa kukosha kwekutarisana nekushanda uye kuwana nzwisiso mumhando dzezvishandiso zvinotarisana zviripo zvakakosha kuti uwane mhedzisiro uye inoyevedza machining mhedzisiro.3.2. Mhando dzeKutarisana Nemidziyo

Maturusi ekutarisana anouya mumhando dzakasiyana, imwe neimwe yakarongedzwa kune chaiyo yakatarisana nezvinodiwa. Ngationgororei mamwe mapoka akajairwa ezvishandiso zvekutarisana nazvo:- 3.2.1. Kutarisana NemaMill: Kutarisana nemagetsi maturusi ekucheka akagadzirirwa mavhisi akatarisana nekumhanya. Iwo anowanzo ratidza akawanda ekucheka macheto kana kuisa, achibvumira kubviswa kwezvinhu zvakanaka. Kutarisana nezvigayo zvakasiyana-siyana uye zvakakodzera kune akasiyana workpiece zvinhu, zvinosanganisira simbi nemapurasitiki.

- 3.2.2. Face Grooving Zvishandiso: Maturusi ekumisikidza kumeso ane hunyanzvi hwekugadzira magororo kana kuzorora pachiso chebasa. Zvishandiso izvi zvinogona kushandiswa kuita senge O-ring grooves kana yekushongedza machining. Maturusi ekumisikidza kumeso anowanikwa mune akasiyana geometries kuti agamuchire chaiwo maprofiles.

- 3.2.3. Misoro Inofinha Yekutarisana: Misoro inobhowa, sezvataurwa muchikamu chakapfuura, inogona zvakare kushandiswa kutarisana nemabasa kana kunyatso kudzora pamusoro penzvimbo yakapera kuchidikanwa. Vanobvumira kuwedzera kwekugadzirisa kune kudzika kwekucheka, kuve nechokwadi chakatarisana nemigumisiro.

3.3. Kusarudza Right Facing Tool

Kusarudza yakakodzera yakatarisana chishandiso kwakakosha kuti uwane kubudirira kutarisana nemabasa. Zvinhu zvakati kuti zvinopesvedzera kusarudzwa kwechombo chinotarisana: 3.3.1. Workpiece Geometry uye Material Kufunga: Funga chimiro uye saizi yeiyo workpiece, pamwe neayo zvinhu. Maturusi akatarisana akasiyana anogona kuve akakodzera kune akafuratira, cylindrical, kana zvisina kurongeka maumbirwo ebasa. Pamusoro pezvo, zvimwe zvinhu zvinogona kuda chaiwo maturusi emidziyo kana machira kuti uwane mhedzisiro yakanaka. 3.3.2. Surface Pedzisa Zvinodiwa uye Sarudzo Yechishandiso: Iyo inodiwa pamusoro pekupedzisira inoita basa rakakosha mukusarudza chishandiso. Pakupedzisa kwepamusoro-soro, zvishandiso zvine mitsetse yakapinza yekucheka uye kugona kugadzirisa zvakanaka zvinosarudzwa. Misoro inofinha, semuenzaniso, inopa kutonga chaiko pamusoro pekupedza kwepamusoro nekuda kwekuwedzera kwekugadzirisa.3.4. Makiyi Matanho eKutarisana Nekubudirira

Kubudirira mukutarisana nemabasa kunoda kutarisisa kune zvakadzama uye nemazvo. Heano mamwe maitiro akakosha ekutarisana neanoshanda:- 3.4.1. Tool Positioning uye Alignment: mira zvakanaka uye gadzirisa yakatarisana chishandiso neworkpiece kuti ive nechokwadi chekubvisa zvinhu uye yakatsetseka, yakatsetseka pamusoro. Kusarongeka kunogona kutungamira kune kusarongeka kwepamusoro uye mhedzisiro yakaipa.

- 3.4.2. Kutarisana Nezvakasiyana Zvishandiso uye Maumbirwo Ekushanda: Kana wakatarisana nezvinhu zvakasiyana, gadzirisa maparamita ekucheka akadai sekucheka kumhanya, chiyero chekudya, uye kudzika kwekucheka zvinoenderana. Ziva nezve chimiro chebasa uye funga kana chishandiso chakasarudzwa chakakodzera iyo chaiyo geometry, kunyanya kana yakatarisana nezvikamu zvisina kuumbwa.

Chikamu 4: Chamfering uye Thread Kucheka Zvishandiso

4.1. Nhanganyaya yeChamfering uye Thread Cutting

Chamfering uye shinda yekucheka akakosha machining maitiro anoshanda akakosha mabasa mumaindasitiri akasiyana. Chamfering inosanganisira kubheza mipendero yemakomba, micheto, kana nzvimbo yebasa, kuvandudza kusimba kwayo, kunaka, uye kuchengeteka. Kucheka shinda ndiyo maitiro ekugadzira screw shinda pane cylindrical workpieces, inogonesa kuungana kwezvikamu kana kupa nzira yekusimbisa. Muchikamu chino, tichaongorora kukosha kwechamfering uye kucheka shinda mukugadzira lathe uye kusuma maturusi anoshandiswa pakuita uku. Chamfering uye shinda yekucheka maturusi midziyo yakasarudzika yakagadzirirwa kuita aya mabasa nemazvo uye nemazvo. Kunzwisisa kukosha kwavo uye mhando dzematurusi aripo kwakakosha kuti uwane zvinodikanwa zvemachining.4.2. Mhando dzeChamfering uye Thread Cutting Tools

Chamfering uye shinda yekucheka maturusi anosanganisira akasiyana mapoka, rimwe nerimwe rakagadzirirwa kune chaiwo machining anodiwa. Ngationgororei mamwe marudzi akajairika ezvishandiso izvi:- 4.2.1. Zvishandiso zveChamfering: Maturusi eChamfering, anozivikanwawo semachamfer mill kana countersinks, akagadzirirwa kugadzira mipendero yakapetwa pane zvebasa. Iwo anouya mumhando dzakasiyana siyana uye saizi, achibvumira machinists kumakomba makomba, mipendero, kana nzvimbo. Zvishandiso zveChamfering zvinowedzera kunaka kweiyo workpiece uye mashandiro, kuderedza mipendero yakapinza, uye kugadzirisa kusangana.

- 4.2.2. Thread Kucheka Zvishandiso: Thread yekucheka maturusi akakosha pakugadzira screw shinda pane cylindrical workpieces. Anouya nenzira dzakasiyana, kusanganisira matepi eshinda dzemukati uye anofira kunze kweshinda. Maturusi ekucheka maturusi anowanikwa kune akasiyana shinda mhando uye mapinji, zvichiita kuti zviite zvakasiyana-siyana kune akasiyana maapplication.

- 4.2.3. Thread Kudzingirira Zvishandiso: Thread kudzingirira maturusi, anowanzo kunzi matambo ekudzingirira, anoshandiswa kugadzirisa kana kudzoreredza tambo dzakakuvadzwa pane zvebasa. Iwo anowanzo shandiswa kana tambo dzekutanga dzakapfekwa kana kukuvadzwa, kuve nechokwadi chekukwana kwezvikamu zvakarukwa. Thread kudzingirira maturusi anouya mune akasiyana dhizaini kuti aenderane chaiwo tambo profiles uye saizi.

- 4.3. Kusarudza Chishandiso Chakakodzera cheChamfering uye Thread Cutting

- 4.3.1. Angle uye Saizi Yekutarisisa: Yezvishandiso zvechamfering, kona yeinodiwa chamfer uye saizi yeworkpiece inosarudza sarudzo yechishandiso. Makona akasiyana anoshanda zvakasiyana-siyana, senge 45-degree chamfers ekushandiswa kwese kana 90-degree chamfers ekugadzira kona chaidzo.

- 4.3.2. Mhando dzeThread uye Pitch Selection: Paunenge uchisarudza maturusi ekucheka shinda, funga nezvemhando yeshinda (semuenzaniso, metric kana yakabatana) uye inodiwa shinda inoyerera. Kufananidza chishandiso kune chaiyo mhando yeshinda kunovimbisa kwakakodzera shinda profiles uye kwakaringana shinda.

4.4. Precision Techniques dzeChamfering uye Thread Cutting

Kuti uwane kunyatsoita chamfering uye shinda yekucheka, zvakakosha kutevedzera zvakanakisa maitiro uye matekiniki. Heano mamwe makuru ekufungisisa:- 4.4.1. Yakakodzera Tool Setup uye Alignment: Ita shuwa kuti chamfering kana shinda yekucheka chishandiso chakachengetedzwa zvakachengeteka uye chakabatana neworkpiece. Kusarongeka kunogona kutungamirira kune zvisiri izvo uye migumisiro yakaipa. Pamusoro pezvo, chengetedza kubvumidzwa kwakakodzera kwemidziyo uye overhang kudzivirira kukanganiswa kwechishandiso.

- 4.4.2. Kuwana Akarurama Thread Profiles uye Chamfer Angles: Yekucheka shinda, tarisa kudzika kweshinda, kukwirira, uye chimiro nekungwarira. Shandisa zviridzwa zvekuyeresa kuti uone kuti shinda dzinosangana nezvinodiwa. Paunenge uchiita chamfer, simbisa kona yechamfer uye zviyero uchishandisa maturusi ekuyeresa akakodzera kuti uwane kupedzisa uye kushanda kwaunoda.

Chikamu 5: Grooving uye Kuparadzanisa Zvishandiso

5.1. Nhanganyaya kune Grooving uye Parting Zvishandiso

Grooving uye kupatsanura mashandiro akakosha kune lathe machining, kushanda mabasa akakosha mukugadzira zvinhu chaizvo. Grooving inosanganisira kucheka zvisaririra kana machani mukati meiyo workpiece, kazhinji nekuda kwezvinangwa sekugara O-mhete, zvindori zvekuchengeta, kana zvekushongedza. Kuparadzanisa, kune rumwe rutivi, inzira yekucheka workpiece kuita zvidimbu zvakasiyana kana kubvisa zvikamu zvisingadiwi. Muchikamu chino, tichaongorora kukosha kwekuita grooving uye kupatsanura uye kusuma maturusi anoshandiswa pamabasa aya mukugadzira lathe machining. Grooving uye maturusi ekuparadzana zviridzwa zvine hunyanzvi zvakagadzirirwa kuita izvi mashandiro nemazvo. Kunzwisisa kukosha kwavo uye kuwana nzwisiso mumhando dzezvishandiso zviripo kwakakosha kuti uwane mibairo chaiyo yekugadzira.5.2. Mhando dzeGrooving uye Kuparadzanisa Zvishandiso

Grooving uye kupatsanura maturusi anosanganisira akasiyana mapoka, rimwe nerimwe rakagadzirirwa kune chaiwo machining anodiwa. Ngationgororei mamwe marudzi akajairika ezvishandiso izvi:- 5.2.1. Zvishandiso zvekuparadzanisa: Maturusi ekuparadzanisa, anozivikanwawo sematurusi ekucheka, akagadzirirwa chaizvo kupatsanura chidimbu chebasa kuita zvidimbu zviviri kana kupfuura. Ivo vane inopinza yekucheka kumucheto uye inowanikwa mumhando dzakasiyana uye saizi. Maturusi ekuparadzanisa anoshandiswa kune maapplication akadai sekucheka chikamu chetsvimbo kana kugadzira akasiyana zvikamu kubva kune imwechete workpiece.

- 5.2.2. Zvishandiso zveGrooving: Zvishandiso zvekuchera zvinoshandiswa kugadzira zviteshi, zvisaririra, kana grooves pamusoro pechishandiso. Zvishandiso izvi zvinouya mumhando dzakasiyana siyana dzejometri kuti dzigadzikane dzakanangana groove profiles. Maturusi eGrooving anosiyana-siyana uye anogona kushandiswa kumashandisirwo akadai sekugadzira makiyi, mapatani ekushongedza, kana kuchengetedza maficha.

- 5.2.3. Kudhinda uye Kuchekwa-Kunopinza:Mamwe lathe maturusi masisitimu anoshandisa shinda uye kucheka-kubvisa ekuisa ayo anogona kushanda ese ari maviri eshinda uye kupatsanura mabasa. Izvi zvinopinza zvakagadzirirwa kugadzira shinda nemazvo uye kucheka maworkpiece zvakachena. Iwo anowanikwa muhukuru hwakasiyana uye shinda profiles kuti aenderane nezvinodiwa chaizvo.

5.3. Kusarudza Chishandiso Chakakodzera cheGrooving uye Kupatsanura

Kusarudza iyo yakakodzera grooving kana yekuparadzanisa chishandiso kwakakosha kuti uwane zvakabudirira machining mhedzisiro. Zvinhu zvakati wandei zvinokonzeresa kusarudzwa kwezvishandiso:- 5.3.1. Upamhi, Hudzamu, uye Kufunga Kwezvinhu: Funga nezvehupamhi hunodiwa hwegoro uye kudzika paunenge uchisarudza maturusi ekuchera. Pamusoro pezvo, iyo workpiece zvinhu zvinopesvedzera kusarudzwa kwechishandiso uye coating, sezvo zvakaoma zvinhu zvingada hunyanzvi maturusi ekucheka kwakanaka.

- 5.3.2. Tool Geometry uye Clearance Angles: Iyo geometry yechishandiso, kusanganisira iyo rake angle, clearance angles, uye yekucheka edge geometry, inoita basa rakakosha mukusarudza chishandiso. Yakakodzera chishandiso geometry inova nechokwadi chekubuda kwechip, kudzikisa masimba ekucheka, uye hupenyu hwekushandisa hwakawedzerwa.

5.4. Matekiniki Anoshanda eGrooving uye Kupatsanura

Kuwana budiriro mukuita grooving nekuparadzana kunoda kunyatsotarisisa maitiro uye maitiro akanaka. Heano maitiro akakosha:- 5.4.1. Workpiece Clamping uye Tool Positioning: Yakakodzera workpiece clamping yakakosha kudzivirira kuzunguzika uye shuwa kuti workpiece inoramba yakachengeteka munzvimbo panguva yegrooving kana kupatsanura. Kumisikidzwa kwematurusi kwakakosha zvakaenzana kuti uwane mhedzisiro yakachena uye chaiyo.

- 5.4.2. Kuwana Kwakachena Kupatsanura uye Grooving Mhedzisiro: Chengetedza akakodzera ekucheka maparamita, akadai sekucheka kumhanya, chiyero chekudya, uye kudzika kwekucheka, kuve nechokwadi chekubuda kwechip uye kushoma kwekushandisa. Wona kuti kuchekwa kwemudziyo kwakapinza, uye shandisa gadziriro yakakodzera yekushandisa kuti uwane migero yakachena uye yakarurama kana mitsara yekuparadzana.

mhedziso

Mugwaro rino rakazara, takaongorora akawanda maturusi ekucheka maturusi anoshandiswa pakuita kwakasiyana siyana, anosanganisira kutendeuka, kufinha, kutarisana, kucheka, kucheka shinda, kucheka, uye kupatsanura. Zvishandiso izvi zvinoita basa rakakosha munyika yekugadzira lathe machining, zvichibvumira machinist kugadzira zvinhu chaizvo uye zvakaomarara mumaindasitiri akasiyana. Chikamu chega chega chegwaro iri chakapa nzwisiso yakakosha mukukosha kwemaitiro chaiwo emuchina uye yakaunza mhando dzematurusi ekucheka anowanzo shandiswa. Takakurukura zvinhu zvinopesvedzera kusarudzwa kwezvishandiso, kukosha kwekuenderana kwezvinhu, uye basa rechishandiso geometry uye kucheka paramita mukuwana mhedzisiro yakanaka. Muchinyorwa ichi chese, takasimbisa kukosha kwekurongeka, kugadzika kwakakodzera kwechishandiso, kurongeka, uye kuomerera kune akanakisa maitiro ekubudirira lathe machining. Kunyangwe iwe uri mudzidzi ari kutsvaga kudzidza izvo zvekutanga kana machinist ane ruzivo ari kutsvaga kuwedzera ruzivo rwako, ruzivo rwuri kuratidzwa pano rwunoshanda seyakakosha sosi yekutarisa uye kunatsiridza hunyanzvi hwako hwekugadzira. Sezvo tekinoroji ichienderera mberi, nyika yemidziyo yekucheka lathe inoramba iine simba uye inogara ichishanduka, ichipa mikana mitsva yekuvandudza uye kunyatsoita mukugadzira. Kunyangwe iwe uri kutendeuka, kufinha, kutarisana, kukwenya, kuruka, kukorokoza, kana kupatsanura, ruzivo rwakapihwa mugwaro rino rinoshongedzera iwe nezvakakosha zvinodiwa kuti ugone mukugadzira lathe machining. Yeuka kuti kusarudzwa kwechishandiso chekucheka chakakodzera uye kubata kwemaitiro chaiwo ndiwo makiyi ekubudirira mukugadzira lathe. Kuramba uchikudza hunyanzvi hwako, kugara uchifambidzana nekufambira mberi kwezvishandiso, uye kugamuchira hunyanzvi nesainzi yekugadzira lathe pasina mubvunzo zvinotungamira mukugadzirwa kwezvakasiyana zvikamu zviri nyore uye zvinoenderana. Sezvo iwe unotanga rwendo rwako mukugadzira lathe machining kana kutsvaga kusimudzira hunyanzvi hwako huripo, dai iri gwara rakazara rishande sereferensi yakakosha uye sosi yekurudziro, ichikugonesa kuvhura iyo yakazara kugona kwemuchina wako welathe uye uwane mhedzisiro inoshamisa mukuedza kwako kugadzira. .

- 5 Sekaiichi machine

- Cnc Kugaya

- Cnc Kutendeuka

- Machining Maindasitiri

- Machining Maitiro

- Surface Kurapa

- Simbi yekushandisa

- Mapepa epurasitiki

- Upfu hweMetallurgy Mould

- Die Casting

- Zvikamu Garari

- Auto Metal Zvikamu

- Machinery Parts

- Akatungamira Heatsink

- Kuvaka Zvikamu

- Sravana Sameeralu Serial XNUMXth Mobile Parts

- Zvikamu Zvekurapa

- Zvikamu Zvemagetsi

- Zvichienderana machine

- Bicycle Parts

- Aluminum machine

- Titanium Kubata

- Stainless Simbi machine

- Mhangura machine

- Brass machine

- Super chiwanikwa machine

- Peek Kugadzira

- UHMW machine

- Sanganisa Machining

- PA6 Kugadzira

- PPS machine

- Teflon Kugadzira

- Inconel machine

- Danho Simbi machine

- Zvimwe Zvinyorwa