Zvakanyatso Tenzi Hunyanzvi Mukuchera uye Cnc Machining Dzidzira!

01 Mazano ekushandisa inotonhorera

Iko kushandiswa kweiyo inotonhorera kwakakosha kuti uwane kuita kwakanaka kwekuchera, zvinokanganisa zvakananga kubviswa kwechip, hupenyu hwezvishandiso uye kunaka kwegomba rakagadzirwa panguva yekugadzira.

(1) Mashandisiro ezvinotonhodza

1) Kutonhora kwemukati dhizaini

Iyo yemukati yekutonhodza dhizaini inogara iri sarudzo yekutanga kudzivirira chip blocking, kunyanya kana machining marefu chip zvinhu uye kudhirowa maburi akadzika (anopfuura katatu dhayamita yegomba). Pachibooreso chakachinjika, kana chinotonhodza chichiyerera chichibuda kubva pachibhorani, hapafanirwe kuve nepasi pemvura yekucheka pamusoro pehurefu hunosvika masendimita makumi matatu.

2) Kutonhora kwekunze kwekugadzira

Kushandiswa kwekunze kunotonhorera kunogona kushandiswa kana chip kugadzirwa kwakanaka uye kudzika kwegomba kusina kudzika. Kuti uvandudze kubuda kwechip, panofanira kunge paine kanozoro imwe chete inotonhorera (kana maviri mhuno kana iri isiri-inotenderera application) padyo neakisi yemidziyo.

3) Dry yekuchera nzira pasina kushandisa inotonhorera

Dry drilling kazhinji hazvikurudzirwe.

- a) Inogona kushandiswa mumashandisirwo ane mapfupi chip zvinhu uye gomba kudzika kusvika katatu padhayamita

- b) Inokodzera horizontal muchina maturusi

- c) Inokurudzirwa kuderedza kasi yekucheka

- d) Upenyu hwemidziyo huchaderedzwa

Inokurudzirwa kusashandisa dry drilling ye:

- a) Stainless simbi zvinhu (ISO M uye S)

- b) Inochinjika bit drill bit

4) Kutonhora kwepamusoro (HPC) (~ 70 bar)

Zvakanakira kushandisa high-pressure coolant ndezvi:

- a) Nekuda kwekuwedzera kutonhora mhedzisiro, hupenyu hwekushandisa hwakareba

- b) Kuvandudza iyo chip yekubvisa maitiro mukugadzira kweakareba chip zvinhu senge simbi isina tsvina, uye inogona kuwedzera hupenyu hwekushandisa.

- c) Zvirinani chip kubviswa kuita, saka kuchengetedzeka kwakanyanya

- d) Ipa kuyerera kwakaringana zvinoenderana nekudzvinyirirwa kwakapihwa uye saizi yegomba kuchengetedza inotonhorera

(2) Shandisa hunyanzvi hwekutonhodza

Iva nechokwadi chekushandisa soluble cutting oil (emulsion) ine EP (yakanyanyisa kudzvinyirirwa) additives. Kuti uve nechokwadi chehupenyu hwematurusi akanakisa, mafuta ari mumafuta-mvura musanganiswa anofanira kunge ari pakati pe5-12% (pakati pe10-15% kana uchigadzira simbi isina tsvina uye superalloy zvinhu). Paunenge uchiwedzera huwandu hwemafuta emucheki wekucheka, iva nechokwadi chekutarisa neanoparadzanisa mafuta kuti uone kuti iyo inokurudzirwa yemafuta haina kupfuura.

Kana mamiriro ezvinhu achibvumidza, chinotonhodza chemukati chinogara chiri sarudzo yekutanga kana ichienzaniswa neyekunze inotonhorera.

Mafuta akachena anogona kuvandudza mafuta ekuzora uye kuunza mabhenefiti pakudhirowa kwesimbi isina tsvina. Iva nechokwadi chekuishandisa pamwe chete neEP additives. Ose ari maviri akasimba carbide drill bits uye indexable yekuisa drill bits anogona kushandisa mafuta akachena uye anogona kuwana mhedzisiro yakanaka.

Mhepo yakamanikidzwa, mhute yekucheka mvura kana MQL (shoma yekuzora) inogona kunge iri sarudzo yakabudirira pasi pemamiriro akagadzikana, kunyanya kana uchigadzira mamwe ma iron iron uye aruminiyamu alloys. Sezvo kuwedzera kwekushisa kunogona kuva nemigumisiro yakaipa pahupenyu hwezvishandiso, zvinokurudzirwa kuderedza kasi yekucheka.

02 Unyanzvi hwekudzora chip

Kugadzira chip uye kubvisa chip inyaya dzakakosha mukuchera, zvichienderana nechinhu chebasa rekushanda, kusarudzwa kwechibhorani / blade geometry, inotonhorera kumanikidza / kugona, uye kucheka paramita.

Kuvhara machipisi kuchaita kuti chibooreso chifambe radially, icho chinozokanganisa kunaka kwegomba, hupenyu hwekudhirowa uye kuvimbika, kana kukonzera kuti chibooreso/blade ipambuke.

Kana machipisi achigona kuburitswa zvakanaka kubva kudhiri bhiti, chip kuumbwa kunogamuchirwa. Nzira yakanakisa yekuziva ndeyekuteerera panguva yekuchera. Ruzha runoramba ruripo runoratidza kubuda kwakanaka kwechip, uye kurira kwepakati kunoratidza chip clogging. Tarisa simba rekudyisa kana simba rekutarisa. Kana pane zvisiri izvo, chikonzero chinogona kunge chakavharika machipisi. Tarisa machipisi. Kana machipisi akareba uye akakombama, asi asina kupetwa, zvinoreva kuti machipisi akavharwa. Ona gomba. Mushure mekuvhara kunoitika, nzvimbo yakaoma ichaonekwa.

Mazano ekudzivisa kucheka:

- 1) Ita shuwa kuti iyo chaiyo yekucheka ma paramita uye drill / chishandiso tip geometry inoshandiswa

- 2) Tarisa chimiro che chip-gadzirisa chiyero chekudya uye nekumhanya

- 3) Tarisa kuyerera kwemvura yekucheka uye kudzvinyirira

- 4) Tarisa kumucheto. Kana iyo chipbreaker yese isiri kushanda, iyo yekucheka kumucheto kukuvara / chip inogona kukonzera refu machipisi

- 5) Tarisa uone kana iyo machinability yakashandurwa nekuda kweiyo batch nyowani yebasa-gadzirisa maparamita ekucheka.

(1) Chips kubva indexable isa drill bits

Iyo tapered machipi akaumbwa nepakati blade ari nyore kuona. Iwo machipisi akaumbwa neanopinda mukati akafanana nekutendeuka.

(2) Machipisi kubva kune yakasimba carbide drill bits

Chipi chinogona kuumbwa kubva pakati pekucheka kusvika kune periphery. Zvakakosha kucherechedza kuti machipisi ekutanga anogadzirwa kana kudhiraivha mukati meiyo workpiece pakutanga anogara akareba, asi izvi hazvikonzeri matambudziko.

(3) Chips kubva kuchinjika bit drills

03Kudzora kwekudya uye kucheka kumhanya

(1) Simba rekucheka kumhanya Vc (m/min)

Pamusoro pekuoma kwezvinhu, kumhanya kwekucheka zvakare ndicho chinhu chikuru chinokanganisa hupenyu hwezvishandiso uye mashandisiro emagetsi.

- 1) Kucheka kumhanya ndicho chinhu chakakosha pakusarudza hupenyu hwechishandiso

- 2) Kucheka kumhanya kuchakanganisa simba Pc (kW) uye torque Mc (Nm)

- 3) Yepamusoro yekucheka kumhanya inoburitsa yakanyanya tembiricha uye kuwedzera flank kupfeka, kunyanya padivi rekushandisa tip

- 4) Paunenge uchigadzira zvimwe zvakapfava zvehurefu chip zvinhu (kureva yakaderera kabhoni simbi), yakakwirira yekucheka kumhanya inoenderana nekugadzira chip.

Kucheka kumhanya kwakanyanyisa:

- a) Iyo flank inopfeka nekukurumidza

- b) Plastic deformation

- c) Hunhu husina kunaka hwegomba uye dhayamita regomba rakashata

Kucheka kumhanya kwakadzikira:

- a) Gadzira bundu rakavakwa

- b) Kubvisa chip kwakashata

- c) Nguva yakareba yekucheka

(2) Simba rekudya fn (mm/r)

- 1) Kukanganisa kuumbwa kwechip, kunaka kwepamusoro uye kunaka kwegomba

- 2) Kupesvedzera simba Pc (kW) uye torque Mc (Nm)

- 3) Kudya kwepamusoro kuchakanganisa simba rekudya Ff (N), iyo inofanirwa kutariswa kana mamiriro ekushanda asina kugadzikana

- 4) Kukanganisa mechanical stress uye thermal stress

High feed rate:

- a) Kupwanya kwakaoma chip

- b) Nguva pfupi yekucheka

- c) Kupfeka kwechishandiso kudiki asi njodzi yekuchera mupendero chipping inowedzera

- d) Hunhu hwegomba hwakaderedzwa

Chiyero chekudya chakaderera:

- a) Machipisi akareba uye matete

- b) Kuvandudzwa kwehutano

- c) Yakakurumidza kupfeka chombo

- d) Nguva yakareba yekucheka

-

e) Pakuchera zvikamu zvitete zvisina kusimba, chiyero chekudya chinofanira kuchengetwa chakaderera

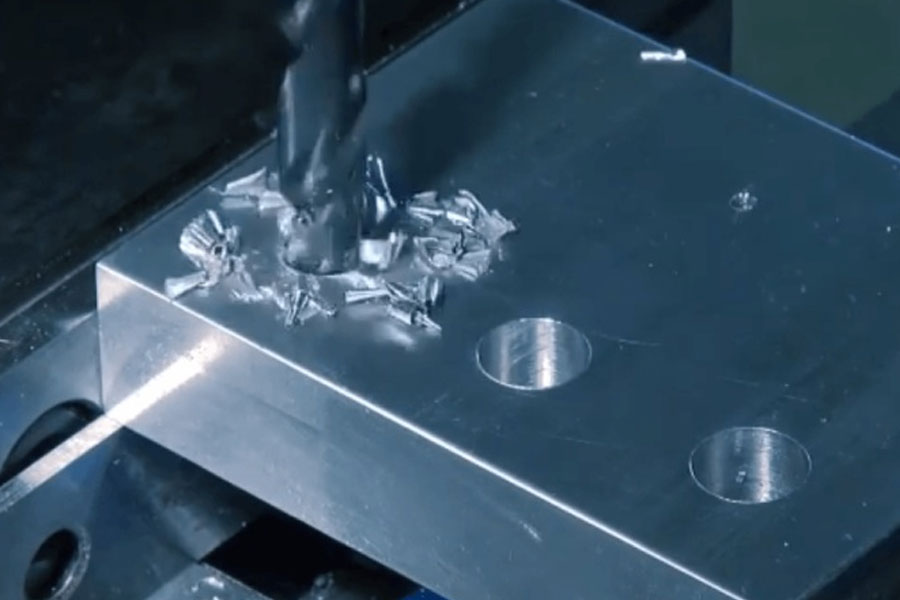

mufananidzo

04Mazano ekuwana maburi emhando yepamusoro

(1) Kubvisa chip

Ita shuwa kuti iyo chip yekubvisa performance inosangana nezvinodiwa. Chip clogging inokanganisa kunaka kwegomba, kuvimbika uye hupenyu hwekushandisa. Iyo yekuchera / isa geometry uye yekucheka ma paramita akakosha.

(2) Kugadzikana, kusungirirwa kwechishandiso

Shandisa chibooreso chipfupi. Shandisa yakakwenenzverwa rigid mudziyo inobata ine diki runout. Ita shuwa kuti muchina chinorukwa chiri muchimiro chakanaka uye chakanyatsoenderana. Iva nechokwadi chokuti zvikamu zvakagadziriswa uye zvakagadzikana. Isa chiyero chekudya chakakodzera chenzvimbo dzisina kujairika, nzvimbo dzakarerekera uye maburi ekuyambuka.

(3) Upenyu hwekushandisa

Tarisa mapfekero eblade uye preset chirongwa chehupenyu hwekushandisa. Iyo inonyanya kushanda nzira ndeye kushandisa feed force monitor kutarisa kuchera.

(4) Kuchengeta

Tsiva blade compression screw nguva nenguva. Chenesa chibatiso chebanga usati watsiva blade, uine chokwadi chekushandisa chipanera che torque. Usapfuure huwandu hwakanyanya hwekupfeka usati wagaya iyo yakasimba carbide drill bit.

05Unyanzvi hwekuchera zvinhu zvakasiyana

(1) Nzira dzekuchera simbi dzakapfava

Kune yakaderera kabhoni simbi iyo inowanzoshandiswa kune welding zvikamu, chip kugadzirwa kunogona kuve dambudziko. Iyo yakaderera iyo kuoma, kabhoni yemukati, uye sarufa yemukati yesimbi, iyo yakareba machipisi anogadzirwa.

- 1) Kana dambudziko rakabatana nekugadzira chip, wedzera kukurumidza kucheka vc uye kuderedza fn yekudya (ndapota cherechedza kuti kana uchigadzira simbi yakajairika, chikafu chinofanira kuwedzerwa).

- 2) Shandisa high pressure uye yemukati inotonhorera yekupa.

(2) Maitiro ekuchera eaustenitic uye duplex Stainless simbi

Austenitic, duplex uye super duplex zvinhu zvinogona kukonzera matambudziko ane chekuita nekuumbwa kwechip uye chip evacuation.

- 1) Iyo chaiyo geometry yakakosha, nekuti inogona kuita kuti machipisi aumbe nenzira kwayo uye kuvabatsira kuti vasunungurwe. Kazhinji kutaura, zviri nani kushandisa inopinza yekucheka. Kana dambudziko rakabatana nekugadzira chip, kuwedzera iyo fn yekudyisa kuchaita kuti chip chiwedzere kutyora.

- 2) Kutonhora kwemukati dhizaini, kudzvanywa kwepamusoro.

(3) CGI (compact graphite cast iron) unyanzvi hwekuchera

CGI kazhinji haidi kutariswa kwakanyanya. Inoburitsa machipisi akakura kupfuura grey cast iron, asi machipisi ari nyore kutyora. Simba rekucheka rakakwirira uye naizvozvo rinokanganisa hupenyu hwematurusi. Inoda kushandisa super kupfeka-resistant zvinhu. Pachave neayo akafanana echishandiso chipfeko chinopfekwa semasimbi ese akakanda.

- 1) Kana dambudziko rakabatana nekugadzira chip, wedzera kucheka kasi Vc uye kuderedza fn yekudya.

- 2) Kutonhora kwemukati kugadzira.

(4) Aluminium alloy drilling unyanzvi

Burr kugadzirwa uye chip evacuation inogona kuve dambudziko. Inogonawo kukonzera hupenyu hupfupi hwekushandisa nekuda kwekunamatira.

- 1) Kuti uve nechokwadi chekugadzirisa chip chip, shandisa kudya kwakaderera uye kukurumidza kucheka.

- 2) Kuti udzivise hupenyu hupfupi hwechishandiso, machira akasiyana angangoda kuongororwa kuti aderedze kunamatira. Aya machira anogona kusanganisira madhaimani majasi, kana pasina machira zvachose (zvichienderana ne substrate).

- 3) Shandisa high-pressure emulsion kana mhute inotonhorera.

(5) Unyanzvi hwekuchera titanium alloys uye high-temperature alloys

Basa rekuomesera kwegomba pamusoro rinokanganisa maitiro anotevera. Zvakaoma kuwana yakanaka chip yekubvisa kuita.

- 1) Paunosarudza geometry yekugadzira titanium alloys, zviri nani kuve neyakapinza yekucheka. Paunenge uchigadzira nickel-based alloys, yakasimba geometry yakakosha. Kana pane dambudziko rekuomesa basa, edza kuwedzera chiyero chekudya.

- 2) High pressure coolant inosvika 70 bar inovandudza mashandiro.

(5) Unyanzvi hwekuchera simbi yakaoma

Wana hupenyu hwekushandisa hunogamuchirika.

- 1) Deredza kasi yekucheka kuderedza kupisa. Rongedza mwero wekudya kuti uwane machipisi anogamuchirwa uye ari nyore-kubvisa.

- 2) High-concentration yakasanganiswa emulsion.

Batanidza kuchinyorwa ichi: Zvakanyatso Tenzi Hunyanzvi Mukuchera uye Cnc Machining Dzidzira!

Dzokorora Chirevo: Kana pasina mirairo yakakosha, zvinyorwa zvese zviri pasaiti ino ndezvepakutanga. Ndokumbira uratidze kwakabva kudhindazve: https://www.cncmachiningptj.com/, thanks!

3, 4 uye 5-axis kunyatsoita CNC machining services ye aruminiyamu machineBeryllium, kabhoni simbi, magnesium; titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite nehuni. Kugona machining zvikamu kusvika 98 in. turning dia. uye +/- 0.001 mukati. kutwasuka kushivirira. Maitiro anosanganisira kugaya, kutenderedza, kuchera, kufinha, kupinza, kubaya, kuumba, knurling, counterboring, countersinking, reaming uye Laser nokuveza. Sekondari masevhisi senge kuungana, isina nzvimbo kukuya, kupisa kurapa, yakanamirwa pamifananidzo uye Welding. Prototype uye yakaderera kusvika yakakwira vhoriyamu kugadzirwa inopihwa nepamusoro 50,000 mayunitsi. Inokodzera fluid simba, pneumatics, hydraulics uye vharafu applications. Inoshanda maindasitiri emuchadenga, ndege, zvechiuto, zvekurapa uye zvekudzivirira.PTJ inoronga zano newe kuti ipe masevhisi anodhura zvakanyanya kuti akubatsire kusvika pachinangwa chako, Unogamuchirwa Kutibata ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

3, 4 uye 5-axis kunyatsoita CNC machining services ye aruminiyamu machineBeryllium, kabhoni simbi, magnesium; titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite nehuni. Kugona machining zvikamu kusvika 98 in. turning dia. uye +/- 0.001 mukati. kutwasuka kushivirira. Maitiro anosanganisira kugaya, kutenderedza, kuchera, kufinha, kupinza, kubaya, kuumba, knurling, counterboring, countersinking, reaming uye Laser nokuveza. Sekondari masevhisi senge kuungana, isina nzvimbo kukuya, kupisa kurapa, yakanamirwa pamifananidzo uye Welding. Prototype uye yakaderera kusvika yakakwira vhoriyamu kugadzirwa inopihwa nepamusoro 50,000 mayunitsi. Inokodzera fluid simba, pneumatics, hydraulics uye vharafu applications. Inoshanda maindasitiri emuchadenga, ndege, zvechiuto, zvekurapa uye zvekudzivirira.PTJ inoronga zano newe kuti ipe masevhisi anodhura zvakanyanya kuti akubatsire kusvika pachinangwa chako, Unogamuchirwa Kutibata ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

- 5 Sekaiichi machine

- Cnc Kugaya

- Cnc Kutendeuka

- Machining Maindasitiri

- Machining Maitiro

- Surface Kurapa

- Simbi yekushandisa

- Mapepa epurasitiki

- Upfu hweMetallurgy Mould

- Die Casting

- Zvikamu Garari

- Auto Metal Zvikamu

- Machinery Parts

- Akatungamira Heatsink

- Kuvaka Zvikamu

- Sravana Sameeralu Serial XNUMXth Mobile Parts

- Zvikamu Zvekurapa

- Zvikamu Zvemagetsi

- Zvichienderana machine

- Bicycle Parts

- Aluminum machine

- Titanium Kubata

- Stainless Simbi machine

- Mhangura machine

- Brass machine

- Super chiwanikwa machine

- Peek Kugadzira

- UHMW machine

- Sanganisa Machining

- PA6 Kugadzira

- PPS machine

- Teflon Kugadzira

- Inconel machine

- Danho Simbi machine

- Zvimwe Zvinyorwa