Kupisa kurapwa tekinoroji yeaviation aluminium alloy

Nekuvandudzwa kwetekinoroji yekufambisa, aluminium alloy yakashandiswa zvakanyanya mumidziyo yendege nekuda kwehuremu hwayo, kusimba kukuru, uye nyore kugadzirisa. Iko kushanda kunoshanda kwealuminium alloy kunoderedza huremu hwechimiro chendege, inovandudza kuita kwendege uye inowedzera mabhenefiti ehupfumi. Naizvozvo, aviation aluminium alloy tekinoroji yakagamuchirawo kutariswa kwakawanda.

Kupisa kurapwa kwealuminium alloy nemhepo inotenderera electric furnace pachinzvimbo che nitrate vira

Chinyakare kupisa kupisa kunoshandisa nitrate choto yekudziya, iyo ine zvakaipira zvakakomba kusvibiswa kwezvakatipoteredza, kushandiswa kwesimba uye marara, nepo mhepo inotenderera yemagetsi vira ine zvakanakira kukurumidza kutanga-up uye yakanaka-yekuchengetedza simba mhedzisiro, uye inodzima yekufambisa nguva. inokurumidza uye inogadziriswa, iyo inogona kusangana nezvinodiwa zveakasiyana aluminium alloy zvikamu. Zvinoda. Mushure mekunge mhepo yekutenderera yevira yemagetsi yapisa, kugadzirisa kudzima hakusvibise iyo inotonhorera, iyo inobatsira kuparidzirwa kushandiswa kweiyo organic quenching svikiro, kuderedza kupisa kurapwa kukanganisa, nekuvandudza kugadzirwa kwehunyanzvi.

Iyo yakakosha tekinoroji yekutenderera kwemhepo yevira yemagetsi ndeyekuita kuve nechokwadi chekufanana kwekushisa kwechoto (± 3 ± ± 5 ℃), kunyanya kuvira hombe, uye maitiro ekuzadzisa zvinodiwa tembiricha yakaderera (100~150 ℃) choto. tembiricha kufanana. Yechipiri kiyi tekinoroji ndeyekuita sei nekukurumidza kudzima nguva yekufambisa, uye inogona kugadziridzwa uye kudzorwa zvinoenderana neakasiyana zvinodiwa zvezvikamu.

Organic quenching medium

Aluminium alloy quenching medium inowanzoshandiswa mvura kana mvura inopisa, asi nokuda kwekupisa kurapwa deformation yakakura kana deformation yakasimba, mvura inopisa haigoni kuzadzisa zvinodiwa, uye organic quenching medium aqueous solution inofanira kusarudzwa. Kushandiswa kwe organic quenching medium aqueous solution pachinzvimbo chemvura pamhepo inotenderera yemagetsi choto kunoderedza kupisa kwekupisa kwealuminum alloy uye nguva yekururamisa jira simbi zvikamu neinopfuura 50%.

Conductivity kuonekwa

Sezvo aruminiyamu alloy zvinhu zvichishandiswa mukugadzira ndege, tensile bvunzo kana kuomarara bvunzo dzakashandiswa kuona kunaka kwealuminium alloy kupisa kupisa. Mushure mokunge aluminium alloy ichipisa-yakagadziriswa, pasi pesimba rimwe (kuoma) kukosha, panogona kuva nematunhu maviri akasiyana, uye zvakasiyana, pasi pehurumende imwe chete, panogona kuva nemasimba maviri akasiyana (kuoma) maitiro. Naizvozvo, kungoshandisa kuomarara kana simba kudzora kunaka kwealuminium alloy mushure mekupisa kurapwa inguva yekuona nzira uye haigone kunyatso kuvimbisa kunaka.

Conductivity yekuona ine yakasarudzika mabhenefiti ekureruka uye nekukurumidza, yakakwira basa kushanda zvakanaka, uye haina kuganhurirwa nechimiro uye uremu hwechikamu chakaongororwa, uye ine yakasarudzika mukana wekusava nekukuvara kune chikamu. Kubva 1980s, conductivity yekuona zvishoma nezvishoma yakashandiswa zvakanyanya mukupisa kurapwa mamiriro ekuongorora ealuminium alloy zvinhu / zvikamu muChina. Mune iyo GB/T12966-1991 "Aluminium Alloy Electrical Conductivity Eddy Current Test Method" chiyero, nzira yekuyedza inopiwa, GJB2894-l997 "Aluminium Alloy Electrical Conductivity and Hardness Requirements", iyo inojekesa iyo magetsi conductivity uye kuoma kukosha zvinodiwa.

Batanidza kuchinyorwa ichi: Kupisa kurapwa tekinoroji yeaviation aluminium alloy

Dzokorora Chirevo: Kana pasina mirairo yakakosha, zvese zvinyorwa zviri pasaiti ino ndezvepakutanga. Ndokumbira utaridze kwakabva kudhindazve: https://www.cncmachiningptj.com

PTJ® igadziri yakasarudzika inopa huwandu hwakazara hwemabhawa emhangura, zvikamu zvendarira uye zvikamu zvemhangura. Maitiro ekugadzira akajairwa anosanganisira kuvhara, embossing, coppersmithing, waya edm masevhisi, kupinza, kuumba nekukotama, kushungurudza, kupisa forging nekutsikirira, kuboora nekurovera, kupeta shinda nekugera, kuveura; akawanda spindle Machining, extrusion uye kuumba simbi uye kutsika. Zvishandiso zvinosanganisira mabara emabhazi, maconductor emagetsi, coaxial tambo, waveguides, transistor components, microwave tubes, blank mold tubes, uye upfu hwesimbi extrusion matangi.

PTJ® igadziri yakasarudzika inopa huwandu hwakazara hwemabhawa emhangura, zvikamu zvendarira uye zvikamu zvemhangura. Maitiro ekugadzira akajairwa anosanganisira kuvhara, embossing, coppersmithing, waya edm masevhisi, kupinza, kuumba nekukotama, kushungurudza, kupisa forging nekutsikirira, kuboora nekurovera, kupeta shinda nekugera, kuveura; akawanda spindle Machining, extrusion uye kuumba simbi uye kutsika. Zvishandiso zvinosanganisira mabara emabhazi, maconductor emagetsi, coaxial tambo, waveguides, transistor components, microwave tubes, blank mold tubes, uye upfu hwesimbi extrusion matangi.

Tiudze zvishoma nezvebhajeti repurojekiti yako uye inotarisirwa nguva yekuendesa. Ticharonga newe kuti tikupe masevhisi anodhura zvakanyanya kuti akubatsire kusvika pachinangwa chako, Unogamuchirwa kutibata isu zvakananga ( sales@pintejin.com ).

- 5 Sekaiichi machine

- Cnc Kugaya

- Cnc Kutendeuka

- Machining Maindasitiri

- Machining Maitiro

- Surface Kurapa

- Simbi yekushandisa

- Mapepa epurasitiki

- Upfu hweMetallurgy Mould

- Die Casting

- Zvikamu Garari

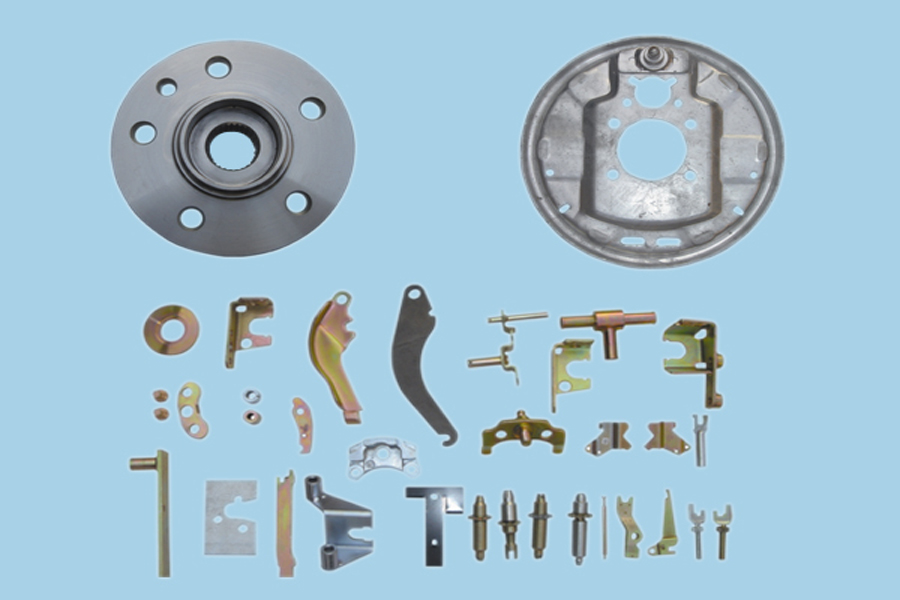

- Auto Metal Zvikamu

- Machinery Parts

- Akatungamira Heatsink

- Kuvaka Zvikamu

- Sravana Sameeralu Serial XNUMXth Mobile Parts

- Zvikamu Zvekurapa

- Zvikamu Zvemagetsi

- Zvichienderana machine

- Bicycle Parts

- Aluminum machine

- Titanium Kubata

- Stainless Simbi machine

- Mhangura machine

- Brass machine

- Super chiwanikwa machine

- Peek Kugadzira

- UHMW machine

- Sanganisa Machining

- PA6 Kugadzira

- PPS machine

- Teflon Kugadzira

- Inconel machine

- Danho Simbi machine

- Zvimwe Zvinyorwa