Mamiriro azvino uye maitiro ekuvandudza mold kupisa kurapwa tekinoroji

Mold kupisa kurapwa inzira yakakosha yekuita kuti mold ishande, uye ine chekuita nekuita kwekugadzira mold kurongeka, kusimba kweforoma, hupenyu hwekushanda kweforoma, mutengo wekugadzira mold, etc. Kubva kuma1980, kukurumidza kukurumidza kwehunyanzvi hwekupisa kupisa kwepasi rose kwave kuri vacuum heat treatment tekinoroji, mold surface inosimbisa tekinoroji uye mold zvinhu pre-kuomesa tekinoroji.

Mold vacuum kupisa tekinoroji

Vacuum heat treatment tekinoroji imhando nyowani yetekinoroji yekurapa kupisa yakagadziriswa mumakore achangopfuura. Iyo ine hunhu hunodiwa nekukurumidza mukugadzira mold, sekudzivirira kudziyisa uye oxidation uye isiri-decarburization, vacuum degassing kana degassing, uye kubvisa Hydrogen embrittlement inovandudza mapurasitiki, kuoma uye kuneta simba rezvinhu (zvikamu). Iyo inononoka vacuum yekudziya uye diki tembiricha musiyano pakati pemukati nekunze kwezvikamu zvinotarisa kudiki deformation yezvikamu zvakakonzerwa neiyo vacuum kupisa kurapwa maitiro.

Iwo mashandisirwo akanyanya mukupisa kwevacuum kupisa kwe mold kudzima mafuta ekutsvaira, vacuum quenching uye vacuum tempering. Kuti uchengetedze hunhu hwakanakisa hwekudziya kwevacuum yebasa rekushanda (senge mold), kusarudzwa uye kuumbwa kweinotonhorera uye kutonhora kwakakosha. Kudzima mold kunonyanya kushandisa kutonhora kwemafuta uye kutonhora kwemhepo. Kune mold yekushanda nzvimbo iyo isingachagadzirwa mushure mekupisa kupisa, vacuum tempering inofanirwa kushandiswa zvakanyanya sezvinobvira mushure mekudzima, kunyanya vacuum-yakadzimwa workpieces (molds), iyo inogona kuvandudza ma mechanic properties ane chekuita nepamusoro pemhando, sekuneta kuita, kupenya kwepamusoro, Corrosion resistance, nezvimwewo.

Kubudirira kwekusimudzira uye kushandiswa kwekombiyuta simulation tekinoroji yekupisa kurapwa inoita kuti hungwaru hwekupisa kurapwa kwe mold hugoneke. Nekuda kweiyo batch diki (kunyangwe chidimbu chimwe chete), maitiro emhando dzakasiyana-siyana dzekugadzirwa kweforoma, uye zvinodikanwa zvakakwirira zvekupisa kurapwa kuita uye hunhu hwekusatendera tsvina, yakangwara kupisa kurapwa kwezviumbwa inova inofanirwa. Nyika dzekunze dzakabudirira, dzakaita seUnited States, Japan, nezvimwewo, dzakasimukirawo nekukurumidza maererano nekubvisa uye kudzima gasi rinopisa, kunyanya kunanga mold.

Mold pamusoro kurapwa zvigadzirwa

Mukuwedzera kune kurongeka kunonzwisisika kwematrix ane simba rakakwana uye kuoma, nzvimbo dzepamusoro dze mold dzakakosha zvikuru pakushanda kwekushanda uye hupenyu hwebasa rehuputi. Iyo yepamusoro yekurapa tekinoroji ye mold injinjini yakarongeka yekushandura morphology, kuumbwa kwemakemikari, chimiro uye kushushikana mamiriro eiyo mold pamusoro kuburikidza nepamusoro pekuvhara, kugadziridzwa kwepamusoro kana komputa tekinoroji yekurapa kuti uwane inodiwa pamusoro pezvivakwa. Parizvino, nitriding, carburizing uye yakaoma firimu deposition inonyanya kushandiswa mukugadzira mold.

Nekuti tekinoroji yenitriding inogona kuumba pamusoro nekuita kwakanakisa, uye iyo nitriding maitiro uye kudzima kwesimbi inofa zvine kurongeka kwakanaka, panguva imwe chete, tembiricha yenitriding yakadzikira, uye hapana chikonzero chekutonhora kwakanyanya mushure mekuita nitriding. uye deformation ye mold idiki zvakanyanya. Kusimbisa kwepamusoro ndiyo yekutanga nitriding tekinoroji, uye zvakare ndiyo inonyanya kushandiswa.

Mold carburizing ndeyekuvandudza simba rose uye kuoma kwe mold, kureva kuti, nzvimbo yekushanda ye mold ine simba guru uye kupfeka kuramba. Yakaomeswa firimu deposition tekinoroji parizvino yakakura CVD, PVD. Molds dzakaputirwa neakaomeswa tekinoroji yefirimu kubvira kuma1980s. Pasi pemamiriro azvino ehunyanzvi, mutengo weakaomeswa firimu deposition tekinoroji (kunyanya midziyo) yakanyanya kukwirira, uye ichiri kungoiswa kune mamwe echokwadi uye akareba-hupenyu mold. Kana nzvimbo yekurapa kupisa yakasimbiswa, mari yekuputira firimu yakaoma ichaderedzwa zvikuru. , Kana mamwe molds akagamuchira tekinoroji iyi, huwandu hwese hwekugadzira mold munyika yedu hunogona kuvandudzwa.

Pre-hardening tekinoroji yezvigadzirwa zve mold

Kubva kuma1970, pfungwa yekufanoomesera yave kutaurwa pasi rese. Zvisinei, nekuda kwezvipingamupinyi zvekuoma kwechigadziro chemuchina wekugadzirisa uye chigadziro chekucheka, kuoma kweiyo pre-kuomeswa hakugoni kusvika pakuoma kwe mold, saka R & D yekudyara mu pre-hardening teknolojia haisi yakakura. Nekuvandudzwa kwekuita kwekugadzirisa maturusi emuchina uye maturusi ekucheka, kuvandudzwa kwe pre-kuomesa tekinoroji yezvigadzirwa zve mold yakawedzera. Pakazosvika ma1980, chikamu chenyika dzepasi rose dzakasimukira dzakashandisa mamodule akaomeswa pamidziyo yepurasitiki yakanga yasvika 30% (ikozvino Pamusoro pe60%).

Iyo pre-yakaomeswa tekinoroji yezvinhu zvekuumbwa munyika yangu ine kunonoka kwekutanga uye diki diki, uye parizvino haigone kuzadzisa zvinodiwa zvekugadzira mold mudzimba. Kushandiswa kwezvinhu zvakafanoomeswa mold zvinogona kurerutsa maitiro ekugadzira mold, kupfupisa kutenderera kwekugadzira mold, uye kugadzirisa iko kurongeka kwekugadzira. Izvo zvinoonekwa kuti nekufambira mberi kwehunyanzvi hwekugadzira, pre-yakaomeswa mold zvinhu zvichashandiswa mune mamwe mold mhando.

Batanidza kuchinyorwa ichi: Mamiriro azvino uye maitiro ekuvandudza mold kupisa kurapwa tekinoroji

Dzokorora Chirevo: Kana pasina mirairo yakakosha, zvese zvinyorwa zviri pasaiti ino ndezvepakutanga. Ndokumbira utaridze kwakabva kudhindazve: https://www.cncmachiningptj.com

PTJ® igadziri yakasarudzika inopa huwandu hwakazara hwemabhawa emhangura, zvikamu zvendarira uye zvikamu zvemhangura. Maitiro ekugadzira akajairwa anosanganisira kuvhara, embossing, coppersmithing, waya edm masevhisi, kupinza, kuumba nekukotama, kushungurudza, kupisa forging nekutsikirira, kuboora nekurovera, kupeta shinda nekugera, kuveura; akawanda spindle Machining, extrusion uye kuumba simbi uye kutsika. Zvishandiso zvinosanganisira mabara emabhazi, maconductor emagetsi, coaxial tambo, waveguides, transistor components, microwave tubes, blank mold tubes, uye upfu hwesimbi extrusion matangi.

PTJ® igadziri yakasarudzika inopa huwandu hwakazara hwemabhawa emhangura, zvikamu zvendarira uye zvikamu zvemhangura. Maitiro ekugadzira akajairwa anosanganisira kuvhara, embossing, coppersmithing, waya edm masevhisi, kupinza, kuumba nekukotama, kushungurudza, kupisa forging nekutsikirira, kuboora nekurovera, kupeta shinda nekugera, kuveura; akawanda spindle Machining, extrusion uye kuumba simbi uye kutsika. Zvishandiso zvinosanganisira mabara emabhazi, maconductor emagetsi, coaxial tambo, waveguides, transistor components, microwave tubes, blank mold tubes, uye upfu hwesimbi extrusion matangi.

Tiudze zvishoma nezvebhajeti repurojekiti yako uye inotarisirwa nguva yekuendesa. Ticharonga newe kuti tikupe masevhisi anodhura zvakanyanya kuti akubatsire kusvika pachinangwa chako, Unogamuchirwa kutibata isu zvakananga ( sales@pintejin.com ).

- 5 Sekaiichi machine

- Cnc Kugaya

- Cnc Kutendeuka

- Machining Maindasitiri

- Machining Maitiro

- Surface Kurapa

- Simbi yekushandisa

- Mapepa epurasitiki

- Upfu hweMetallurgy Mould

- Die Casting

- Zvikamu Garari

- Auto Metal Zvikamu

- Machinery Parts

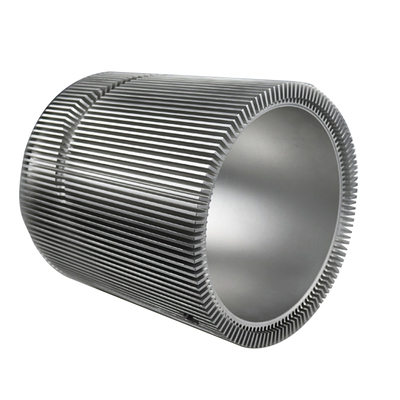

- Akatungamira Heatsink

- Kuvaka Zvikamu

- Sravana Sameeralu Serial XNUMXth Mobile Parts

- Zvikamu Zvekurapa

- Zvikamu Zvemagetsi

- Zvichienderana machine

- Bicycle Parts

- Aluminum machine

- Titanium Kubata

- Stainless Simbi machine

- Mhangura machine

- Brass machine

- Super chiwanikwa machine

- Peek Kugadzira

- UHMW machine

- Sanganisa Machining

- PA6 Kugadzira

- PPS machine

- Teflon Kugadzira

- Inconel machine

- Danho Simbi machine

- Zvimwe Zvinyorwa