Chimiro chekusimudzira uye yakazvimirira innovation zano rewelding indasitiri

1. Chinzvimbo uye basa muindasitiri yekugadzira michina

Welding inyanzvi yekugadzira iyo inobatanidza zvachose zvinhu uye inova chimiro chine basa rakapihwa. Zvinenge zvigadzirwa zvese, kubva kumazana ezviuru zvematani emavhiri mahombe kusvika kuzvinhu zvemagetsi zvisingasviki giremu imwe, zvinoshandisa tekinoroji yewelding kusvika kumadhigirii akasiyana mukugadzira kwavo. Welding yakapinda munzvimbo dzese dzeindasitiri yekugadzira, ichibata zvakananga kunaka, kuvimbika uye hupenyu hwezvigadzirwa, pamwe nemitengo yekugadzira, kushanda nesimba uye kukurumidza kupindura kwemusika.

Simbi yeChina yakabuda muna 2005 yakasvika 349 miriyoni matani, ikava mugadziri mukuru wesimbi pasi rose uye mutengi, uye huwandu hwesimbi yakashandiswa muzvivakwa zvakashongedzerwa yakapfuura 130 miriyoni matani, iyo yakaenzana nesimbi yakabuda muUnited States mugore rimwe chete, zvichiita. hazvina kumboitika munyika. Mugadziri mukuru we welded steel structures.

Tichitarisa kubva kune mamwe mapurojekiti akakosha akapedzwa muChina muna 2005, tekinoroji yewelding yakaita basa rakakosha. Semuyenzaniso, iyo hydropower michina yeTatu Gorges Project ihombe yewelding system, inosanganisira pombi dzemvura, mavhoruti, anomhanya, makuru. mugodhis, mabhesi ejenareta, zvichingodaro. Martensitic Stainless steel runners ane dhayamita inosvika 10.7 m uye kureba 5. 4 m inorema matani 440, ndiyo mumhanyi mukuru pasi rose wecast-welded structure. Mumhanyi anosungwa nekorona yepamusoro, mhete yepasi uye 13 kana 15 mashizha. Welding yemumhanyi wega wega inoda 12 ton welding wire, izvo zvinotora anopfuura mwedzi mina. Kuvhurwa kwakabudirira uye kudzoreredzwa kwechitundumuseremusere cheShenzhou-4 kwakaratidza kufambira mberi kukuru muindasitiri yezvemuchadenga yeChina. The return capsule uye orbital module apo vaviri vemuchadenga vakatamiswa zvese zvakashongedzwa zvimiro zvealuminium alloy, uye mhepo uye deformation control yemajoini akakwenenzverwa aive akakosha Kiyi yekugadzira welding. Pakupera kwa6, yekutanga hydrogenation reactor yeChina yekutanga yakananga marasha liquefaction unit yakagadzirwa neFirst Heavy Machinery Group yeShenhua Company, ine dhayamita ye2005 m, kureba 5.5 m, ukobvu hwe62 mm, uye. huremu hwematani 337, ndiyo huru pasi rose nhasi. , Chinorema forging-welding dhizaini hydrogenation reactor, inotora iyo yakazara otomatiki kaviri-waya yakamanikana gap yakanyura arc welding tekinoroji ine yakazvimirira kodzero yezvivakwa muChina, uye yega yega weld inoda kusungirirwa nguva dzose kwemazuva mashanu. Iyo West-East Gasi Pipeline yakareba 5 km. Ndiyo yekutanga yeChina yakakwirira-simba simbi (X4,000) hombe-dhayamita refu-refu pombi. Mapaipi esimbi espiral uye longitudinal seam simbi pombi anoshandiswa ese mapombi akaiswa muchimiro cheplate-welding. Muna 70, matani ose ekuvaka ngarava dzenyika yangu akasvika 2005 miriyoni matani, achiverengera 12.12% yepasi rose kuvaka ngarava. Iri pachinhanho chechitatu pasi rose ichitevera Japan neSouth Korea, uye iri kufamba yakanangana nepasi rose nekubuda kwepagore kwematani mamiriyoni makumi maviri nemashanu. Iyo inogadzirwa mudzimba 17-ton supertanker, ngarava nyowani ye25 TEU, 300,000-ton yakawanda inotakura, uye ngarava zana nemakumi manomwe inozivikanwa se "China's First Shield" iyo yakwezva kutarisisa pasi rose kudada kweindasitiri yeChina yekugadzira ngarava. Iyo yakajairika bhodhi-welded chimiro. Pamusoro pezvo, Shanghai Zhonglupu Bridge ndiro bhiriji resimbi rakareba kwazvo pasi rose; iyo ellipsoidal dome yeNational Center for the Performing Arts ndiyo inorema pasi rose simbi yakagadzirwa; shiri dendere resimbi chimiro cheOlympic main stadium iri kuvakwa inorema kupfuura 5668 tons , Ndiyowo yakanakisa munyika. Aya mahombe-akakura zvimiro ndiwo akakura, anorema, akareba, akareba, akakora, uye mutsva anomiririra uye zvakakosha zvigadzirwa zvinogadzirwa muChina. Zvinogona kuonekwa kuti welding ine nzvimbo yakakosha zvikuru uye basa mukusimudzira hupfumi hwenyika uye kuvaka kwekudzivirira kwenyika.

Zvinogona kuoneka kubva mukutsvagisa nekusimudzira mapurojekiti emakumi maviri makuru emhando yezvigadzirwa zvehunyanzvi mu "Eleventh Five-Year Plan" iyo miriyoni-kilowatt nuclear power unit, Ultra-supercritical thermal power generator, high-head ultra-large-capacity hydropower. mayuniti, uye yakakura-pamwero pumped okuchengetera Units, zvakakwana seti hwokugadzira midziyo nokuda 20-30-watt circulating fluidized mubhedha (CFB) boilers, hombe megaton-kirasi ethylene zvinomera, mega-tonne hombe-mwero terephthalic acid zvinomera, hombe- zviyero zvemarasha-kune-gasi zvidyarwa, uye migodhi mikuru yemarasha Pakati pemigodhi yakabatanidzwa tekinoroji uye midziyo, kugadzira welding ndeimwe yenzira dzinokosha dzekugadzira.

2. Ongororo yeindasitiri yakazvimirira yekuvandudza kugona

2.1 Mamiriro ezvinhu ehunyanzvi hweindasitiri

Kubva pakavambwa New China, kunyanya mumakore makumi maviri neshanu ekugadzirisa nekuvhura, China yakatsvaga yakazvimirira, yakagadzira uye yakaunza mimwe michina yemhando yepamusoro, matekinoroji uye zvinhu. Parizvino, nzira dzakakura dzekushongedza uye midziyo yakashandiswa mukugadzira munyika inoshandiswawo muChina, asi kudzika uye hupamhi hwekushandisa kwakasiyana. MaChina ekugadzira makambani ave kutotora matekinoroji akadai seyemagetsi beam welding, laser welding, laser brazing uye. Laser nokuveza, Laser uye arc yakasanganiswa kupisa sosi welding, imwe-waya kana mapatya-waya yakatetepa-gap yakanyura arc welding, 4-waya yakakwirira-kumhanya yakanyudzwa arc welding, uye mbiri-waya pulsed welding. Gasi yakadzivirirwa welding, plasma arc welding, yakanaka plasma arc yekucheka, jet yemvura yekucheka, CNC yekucheka system, robhoti welding system, welding flexible production line (W-FMS), variable polarity welding power supply, surface tension transition welding power supply (STT) uye yakazara Digital welding simba rekupa, etc. Kunyange friction inomutsa welding tekinoroji, iyo parizvino yakakurumbira munyika, yakashandiswa pakugadzira zvigadzirwa. Iyo nhanho yekugadzira welding tekinoroji muChina yakagadziridzwa zvakanyanya, asi kukomba kwematambudziko aripo hakugone kufuratirwa.

2.2 Mamiriro ekuvandudza tekinoroji yekunze

Nyika dzakasimukira pasirese dzinokoshesa zvikuru kusimudzira nekuvandudza tekinoroji yewelding. Nyanzvi dzeAmerica neGerman dziri kukurukura nezve basa uye kutungamira kwekutungamira kwewelding muzana ramakore re21. Yakabvumirana kuti:

1. Welding (ne 2020) icharamba iine yakakosha yekugadzirisa tekinoroji muindasitiri yekugadzira. Iyo chaiyo, yakavimbika, yakaderera-mutengo, uye yepamusoro-tech nzira yekujoinha zvinhu. Parizvino, hapana imwe nzira inogona kushandiswa zvakanyanya pakubatanidza simbi pane welding uye kuwedzera hukuru hwakawedzerwa kukosha kune zvigadzirwa zvakasungwa.

2. Welding tekinoroji (kusanganisira kujoinha, kucheka, kupfekedza) ikozvino uye mune ramangwana ndiyo inosarudzika nzira yekugadzira iyo inowanzobudirira kugadzira zvinhu zvakasiyana-siyana muzvigadzirwa zvinogona kuiswa pamusika.

3. Welding haisisiri "call-to-call process", zvishoma nezvishoma ichabatanidzwa muhupenyu hwose hwechigadzirwa, kubva pakugadzira, kubudirira, kugadzira kusvika pakugadzirisa nekugadzirisa zvakare.

4. Welding ichaonekwa senzira yakakosha yekuvandudza mutengo, kunaka uye kuvimbika kwehupenyu hwechigadzirwa, uye ichaitawo mupiro unokosha mukuvandudza kukwikwidza kwemusika.

2.3 Matambudziko uye mapeji mudzimba yakazvimirira yekuvandudza kugona

2.3.1 Dambudziko

Zvichienzaniswa nenyika dzekunze, pazere, nhanho yekugadzira uye otomatiki yekugadzira mudzimba welding yakaderera, uye nhanho yehunyanzvi hwekugadzira welding, welding midziyo, uye welding zvinhu zvinodiwa nemakambani mazhinji, eChina, uye ayo "akakura uye akapararira. yakashandiswa" Kana ichienzaniswa neyekucheka-kumucheto welding tekinoroji, inosarira kumashure kwenyika dzekunze. Nekudaro, kumabhizinesi akakosha ari pamusoro pechikamu chepakati mumaindasitiri emotokari, kuvaka ngarava, mota dzenjanji, magetsi chiteshi boilers, midziyo yekugadzira magetsi, muchina unorema, michina yekuvaka, midziyo, nezvimwe, vakaunza imwe yekunze yemhando yepamusoro yewelding michina yakawanda yetekinoroji. shanduko kubva pakuvandudzwa uye kuvhurwa. , Zvishandiso uye maitiro, uye tekinoroji nhanho yekugadzira welding yakagadziridzwa zvakanyanya. Inogona kusvika padanho repedyo neiyo yemabhizinesi ekunze akafanana. Inogona kugadzira michina uye zvigadzirwa zvinodiwa nehupfumi hwenyika uye kuvaka kwekudzivirira kwenyika. Ndiko chete kushandisa uye kushandiswa kwetekinoroji yepamusoro. Huwandu uye nhanho yepamusoro yetekinoroji yakasiyana neiyo yemakambani ekunze. Nekudaro, zvinofanirwa kucherechedzwa kuti pachine kushaikwa kwemichina yemhando yepamusoro yekushongedza, yepamusoro-yekupedzisira welding zvinhu uye inobudirira welding tekinoroji ine mabhureki akazvimirira muChina. Parizvino, mazhinji eaya epamusoro welding midziyo uye zvinhu zvinoshandiswa nemabhizinesi zvinotsamira kune kunze kwenyika. Iyo inobwinya pamusoro uye hollow tekinoroji yekugadzirwa kwemumba welding isimba rakakomba kushaya simba.

Pane zvikonzero zvakawanda nei iyo yekumba welding innovation kugona isiri yakakwirira:

(1) Kubva padanho renyika, madhipatimendi ehurumende akakodzera anoshaya kunzwisisa kwakadzama uye kwakarurama kwechinzvimbo uye kukosha kwehunyanzvi hwekugadzira welding mukusimudzira hupfumi hwenyika uye kuvaka kwedziviriro yenyika; kushaikwa kwehunyanzvi hwekuvandudza tekinoroji yewelding mukupindura kusimudzirwa kwehupfumi uye kukwikwidza kwemusika kunoda Kutungamira kuronga; kunyanya kutsvaga kwepamusoro-tekinoroji uye yakanyanyisa, uku uchiregeredza kuvandudzwa kweiyo basic welding tekinoroji.

(2) Semaonero ezvikoro zvedzidzo yepamusoro, gore ra1998 risati rasvika, zvikoro zvedzidzo yepamusoro zvinopfuura 50 muChina zvakanga zvatanga zvikoro zvepamusoro zvewelding, uye gore negore zvaidzidzisa zviuru zvevanhu vanenge vapedza zvidzidzo zvewelding kunyika. Mushure mekushandiswa kwedzidzo yeruzhinji, Bazi reDzidzo rakangobvumidza imwe Harbin Institute of Technology kuchengetedza yakazvimiririra welding huru, uye kurima 70 kusvika 80 welding madhigirii eBachelor, uye nezve 70 welding masters uye vanachiremba gore rega rega. Iwo welding dzidziso uye zvikamu zvekutsvagisa zvemamwe mayunivhesiti anonyanya kupihwa zita rekuti welding research masangano. Pasi pechisimbiso chedzidzo yepasirese, vamwe vadzidzi mune zvekushandisa kana madhipatimendi emuchina vanosarudza zvidzidzo zvewelding, asi makosi ehunyanzvi ane chekuita newelding akaderedzwa neinopfuura hafu yemaawa ekutanga ezvidzidzo. Nekuda kwekushaikwa kwekuenderera mberi nedzidzo uye masisitimu ekudzidzisa ehunyanzvi muChina, ava vakapedza kudzidza kuyunivhesiti vanoda nguva yakati rebei pa-basa yekudzidzira kuita basa rekugadzira tekinoroji nekusimudzira.

Parizvino, makoreji epamba nemayunivhesiti, kunyanya mayunivhesiti anozivikanwa, ane masimba akasimba ekuvandudza. Ivo vari kuita welding tekinoroji yekutsvagisa minda, uye ivo vanonyanya kurerekera kune otomatiki kutonga, marobhoti, nhamba simulation, welding (kubatana) kwezvinhu zvitsva, uye zvemagetsi. Yepamusoro-tekinoroji zvinhu senge beam welding uye laser welding. Izvo zvinodikanwa kudzidza aya epamusoro-tekinoroji uye akaomesesa matekinoroji, ayo anogona kusangana nezvinodiwa zveminda yakakosha uye zviri nyore kuwana mari kubva kumadhipatimendi ehurumende. Zvakadaro, chiyero chekushandiswa kwetekinoroji iyi idiki, uye kukanganisa mukusimudzira hupfumi hwenyika kudiki. Nekudaro, kune mashoma mashoma emayunivhesiti anoomerera pakutsvaga "zvakajairika" welding zvinhu, welding tekinoroji uye welding simba innovation. Semuyenzaniso, kuburitswa kwepagore kweChinese manual welding electrode inodarika matani 1.5 miriyoni, inova ndiyo yakakura pasi rose inogadzira maelectrode. Iyi inofanira kunge iri pfungwa yakasimba yeChina. Nekudaro, nekuda kwekushaikwa kwenguva refu kweyakadzama basic theoretical research, mhando uye tekinoroji yeChina welding electrode yakasarira kumashure kwenyika dzekunze kwenguva yakareba. , Uye kufambira mberi kunononoka. Tsvagiridzo pamushini wemagetsi welding uye arc fizikisi inenge yapera.

(3) Kubva pamaonero emasangano ekutsvagisa welding, China yakagadzira masangano ekutsvagisa welding-Harbin Welding Research Institute uye Chengdu Electric Welding Machine Research Institute neBazi reMichina Indasitiri muma1950s. Mamwe madhipatimendi eindasitiri akagadzirawo masangano ekutsvagisa anowirirana, asi mazhinji acho ari munzvimbo dzekutsvagisa nenzira yezvikamu nemahofisi, senge imba yekubatira yeCentral Iron uye Steel Research Institute, imba yekubatira yeInstitute of. Metallurgical Construction, uye Institute of Ship Technology. Imba yekusvina, imba yekubatira yeAeronautical Manufacturing Engineering Research Institute, etc. Harbin Welding Research Institute ndiyo chete yakazara tsvakurudzo Institute of welding technology muChina. Nzvimbo dzayo dzekutsvagisa dzinosanganisira welding zvinhu, zvinhu weldability, welding tekinoroji, welding midziyo, isinga paradza kuyedza, nezvimwewo; indasitiri sevhisi nzvimbo dzepakati dzinosanganisira Secretariat yeNational Welding Society uye National Welding Association Secretariat, National Welding Standardization Technical Committee Secretariat, National Welding Material Quality Supervision uye Inspection Center, Welding Magazine, etc. Kwemakore makumi mashanu apfuura, masangano ekutsvakurudza aya ane yakaita zvakakosha mukusimudzira hupfumi hweChina uye kuvaka kwedziviriro yenyika. Panguva imwecheteyo, ivo vakagadzirawo mabhesi ekutsvagisa ane hunyanzvi hwekutsvagisa uye kuyedza zviridzwa nemidziyo, uye vakarima timu yezvidzidzo zvakasiyana uye ruzivo rwakapfuma. , Chikwata chesainzi uye tekinoroji chinoziva nezvekugadzira chakagadzira mamiriro akanaka ekutsvaga kwesainzi. Nekuvandudzwa kwekuvandudzwa, mamwe makurukota eindasitiri akabviswa, uye anopfuura mazana maviri masangano ekutsvagisa akashandurwa kuita mabhizinesi ane tekinoroji. Nekudaro, nyika inoisa sei zvine hungwaru aya masangano ekutsvagisa uye ibasa ripi ravanofanira kuita mukutsvagisa kwesainzi uye hunyanzvi hweaya akashandurwa masangano ekutsvagisa? , Hazvina kujeka.

(4) Kubva padanho rebhizinesi, 2006 National Sainzi neTekinoroji Musangano wakaratidza pachena kuti mabhizinesi anofanirwa kuita basa guru mukuvandudza tekinoroji. "Nyaya" hairevi kuzviita uri wega kana kutanga kubva pakatanga. Hurumende inofanirwa kukurudzira vemabhizinesi kuti vatungamire, vaise misoro inoda kuongororwa uye kugadziriswa pachine nguva, uye kusimbirira pamubatanidzwa wekugadzira, dzidzo uye kutsvagisa kuita tsvakiridzo isati yaitwa; Nyika inofunga kuti mabhizinesi anotora chinzvimbo chikuru chinodikanwa chenguva refu, uye haasi mabhizinesi ese anogona kuzviita ipapo. Parizvino, mazhinji eiyo R&D masimba emabhizinesi haana kusimba, uye hazvigoneke uye hazvifanirwe kunge zvakazara. Mabhizinesi ekugadzira zvigadzirwa anonyanya kuita hunyanzvi hwekugadzira uye manejimendi, uye kuvandudza tekinoroji yakajairwa tekinoroji kunofanirwa kutsamira zvakanyanya pakutsvagisa munharaunda nekusimudzira masimba-mayunivhesiti, masangano ekutsvagisa uye ane hukama mabhizinesi ehunyanzvi. Munguva kubva 2002 kusvika 2003, chirongwa chekubvunza cheAcademy of Engineering chakaita ongororo ye115 epakati kusvika kune makuru emabhizinesi. Pakati pevadzidzisi vewelding 2,012, mumwe chete ndiye aive nedhigirii reDhigirii, asi pasi pe2% aive nedhigirii remasters. Iwo matekinoroji mune mamwe maitiro mubhizinesi anogona kunge asiri nani zvakanyanya. Mhedzisiro iyi inonyatsoratidza kushomeka kwehunyanzvi hwekuita innovation mumakambani azvino ekugadzira.

Batanidza kuchinyorwa ichi: Chimiro chekusimudzira uye yakazvimirira innovation zano rewelding indasitiri

Dzokorora Chirevo: Kana pasina mirairo yakakosha, zvese zvinyorwa zviri pasaiti ino ndezvepakutanga. Ndokumbira utaridze kwakabva kudhindazve: https://www.cncmachiningptj.com

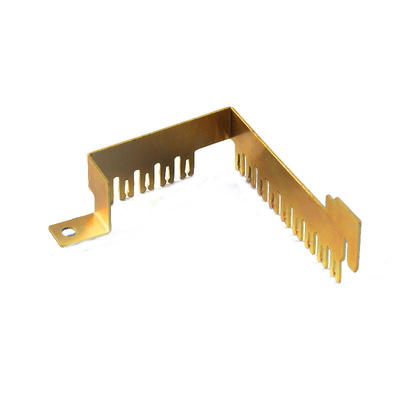

PTJ® igadziri yakasarudzika inopa huwandu hwakazara hwemabhawa emhangura, zvikamu zvendarira uye zvikamu zvemhangura. Maitiro ekugadzira akajairwa anosanganisira kuvhara, embossing, coppersmithing, waya edm masevhisi, kupeta, kuumba nekukotama, kugumburisa, kupisa kuforoma nekutsikirira, kuboora nekubaya, kupeta shinda nekukochekera, kugera, akawanda spindle Machining, extrusion uye kuumba simbi uye kutsika. Zvishandiso zvinosanganisira mabara emabhazi, maconductor emagetsi, coaxial tambo, waveguides, transistor components, microwave tubes, blank mold tubes, uye upfu hwesimbi extrusion matangi.

PTJ® igadziri yakasarudzika inopa huwandu hwakazara hwemabhawa emhangura, zvikamu zvendarira uye zvikamu zvemhangura. Maitiro ekugadzira akajairwa anosanganisira kuvhara, embossing, coppersmithing, waya edm masevhisi, kupeta, kuumba nekukotama, kugumburisa, kupisa kuforoma nekutsikirira, kuboora nekubaya, kupeta shinda nekukochekera, kugera, akawanda spindle Machining, extrusion uye kuumba simbi uye kutsika. Zvishandiso zvinosanganisira mabara emabhazi, maconductor emagetsi, coaxial tambo, waveguides, transistor components, microwave tubes, blank mold tubes, uye upfu hwesimbi extrusion matangi.

Tiudze zvishoma nezvebhajeti repurojekiti yako uye inotarisirwa nguva yekuendesa. Ticharonga newe kuti tikupe masevhisi anodhura zvakanyanya kuti akubatsire kusvika pachinangwa chako, Unogamuchirwa kutibata isu zvakananga ( sales@pintejin.com ).

- 5 Sekaiichi machine

- Cnc Kugaya

- Cnc Kutendeuka

- Machining Maindasitiri

- Machining Maitiro

- Surface Kurapa

- Simbi yekushandisa

- Mapepa epurasitiki

- Upfu hweMetallurgy Mould

- Die Casting

- Zvikamu Garari

- Auto Metal Zvikamu

- Machinery Parts

- Akatungamira Heatsink

- Kuvaka Zvikamu

- Sravana Sameeralu Serial XNUMXth Mobile Parts

- Zvikamu Zvekurapa

- Zvikamu Zvemagetsi

- Zvichienderana machine

- Bicycle Parts

- Aluminum machine

- Titanium Kubata

- Stainless Simbi machine

- Mhangura machine

- Brass machine

- Super chiwanikwa machine

- Peek Kugadzira

- UHMW machine

- Sanganisa Machining

- PA6 Kugadzira

- PPS machine

- Teflon Kugadzira

- Inconel machine

- Danho Simbi machine

- Zvimwe Zvinyorwa