Matekiniki eCNC Kutendeutsa kune Zvikamu-zvakatetepa-madziro

Inonyanya kukosha yeCNC

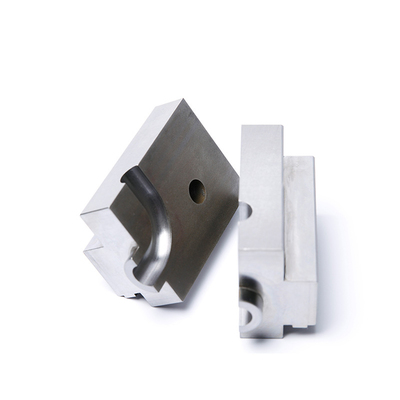

Muchigadziro chekucheka, rusvingo rwakaonda runokanganiswa nyore nyore nesimba rekucheka, izvo zvinotungamirira pakuonekwa kweovha kana "chiuno chechiuno" chine pakati nepakati uye migumo mikuru. Mukuwedzera, yakaonda-madziro bushings inotarisana nekupisa kwekupisa nekuda kwekushayikwa kwekupisa kupisa panguva yekugadziriswa, uye zvakaoma kuve nechokwadi chekugadzirisa kunaka kwezvikamu. Zvikamu zvinoratidzwa mumufananidzo pazasi hazvisi chete zvinokanganisa kuisa uye kusungirira, asi zvakare zvakaoma kugadzirisa zvikamu zvakagadziriswa. Izvo zvinodikanwa kugadzira yakakosha yakaonda-walled casing uye mugodhi chengetedza.

▌ Kuongororwa kwemaitiro

Zvinoenderana nezvinodiwa zvehunyanzvi zvinopihwa mukudhirowa, iyo workpiece inogadziriswa nesimbi isina musono pombi. Kushata kwepamusoro kwegomba remukati uye madziro ekunze ndeye Ra1.6μm, iyo inogona kuwanikwa nekutendeuka, asi cylindricity yegomba remukati ndeye 0.03mm, iyo inodiwa kune dzakatetepa-madziro mativi Pamusoro. Mukugadzirwa kwakawanda, nzira yekugadzira inenge: blanking-kupisa kurapwa-mota kupera kumeso-mota yekunze denderedzwa-mota yemukati gomba-mhando yekuongorora.

Iyo "yemukati gomba machining" maitiro ndiyo kiyi yekutonga kwemhando. Zvakaoma kwatiri kucheka gomba remukati pasina denderedzwa rekunze uye rakatetepa-madziro casing kuvimbisa 0.03mm silinda.

▌ Iyo kiyi tekinoroji yegomba remota

Iyo yakakosha tekinoroji yekutendeuka gomba ndeyekugadzirisa dambudziko rekuomarara uye chip kubviswa kwemukati gomba kutendeuka chishandiso. Kuti uwedzere kuomarara kweiyo yemukati gomba rekushandura chishandiso, tora matanho anotevera:

(1) Edza kuwedzera mhiri-chikamu nzvimbo yemudziyo wemidziyo, kazhinji muromo wegomba remukati rekushandura mudziyo uri pamusoro pechibatiso, kuitira kuti mhiri-chikamu nzvimbo yemudziyo ishoma, kushoma. kupfuura 1/4 yenzvimbo yakachinjika yegomba, sezvakaratidzwa mumufananidzo wekuruboshwe pazasi. Kana iyo muromo weiyo yemukati gomba inotenderedza chishandiso iri pamutsara wepakati pechibatiso, iyo mhiri-chikamu nzvimbo yemudziyo inobata mugomba inogona kuwedzerwa zvakanyanya, sezvinotevera.

(2) Kureba kwechibatiso chekushandisa kunofanirwa kureba kusvika 5-8mm sehurefu hwechigadzirwa chakagadziriswa, kuitira kuti uwedzere kusimba kwechibatiso chekutendeuka uye kuderedza kuzununguka panguva yekucheka.

▌ Gadzirisa dambudziko rekubvisa chip

Kunyanya kudzora nzira yekucheka yekubuda. Iyo yakakasharara yekuchinjisa chishandiso inoda machipisi kuti ayerere kumusoro kuti agadzirwe (kumberi chip kubviswa). Nechikonzero ichi, gomba remukati rekushandura chishandiso chine mupendero wakanaka chinoshandiswa, sezvinoratidzwa mumufananidzo uri pazasi.

Kana wapedza kutendeuka, zvinodikanwa kuti machipisi ayerera akananga pakati kunorereka chip kumberi (gomba repakati chip kubviswa), saka kana uchirodza chishandiso, teerera kune nzira yekukuya yekucheka, uye nzira yekubvisa chip. kurerekera arc yakananga kumberi, sezvinoratidzwa pamufananidzo uri pazasi wekutenderera zvakanaka Iyo banga alloy inoshandisa YA6, yazvino M mhando, ine zvirinani kushanduka simba, kupfeka kuramba, kukanganisa kuoma, uye kuramba simbi uye tembiricha.

Kana uchirodza, kona yerake inotenderedzwa kune arc-yakaita angle ye 10-15 °, uye kona yekumashure iri 0.5-0.8mm kure nemadziro zvichienderana neiyo machining arc (iyo yezasi mutsara wechishandiso uri muradian), uye kona yekucheka ye c ndiyo §0.5-1. Iyo wiper pa point B ye chip edge ndeye R1-1.5, iyo yekubatsira kona yekuyamura inodzika kusvika 7-8 °, uye poindi AA yeE yemukati mupendero inogadzika kuita denderedzwa kubvisa machipisi.

▌ Nzira yekugadzirisa

(1) Murindi we shaft anofanira kuitwa asati agadziriswa. Chinangwa chikuru chemugadhi we shaft kuvharisa buri remukati remota yakatetepa-yakakomberedzwa nehukuru hwepakutanga, uye kuigadzirisa neyekumberi uye yekumashure nzvimbo kuti igadzirise denderedzwa rekunze pasina deformation, uye kuchengetedza mhando uye. kururama kwedenderedzwa rekunze. Naizvozvo, kugadziridzwa kweiyo shaft gadhi ndiyo kiyi chinongedzo mukugadzirisa kutetepa-kumadziro casing.

45﹟Carbon chimiro chakatenderedza simbi inoshandiswa kugadzirisa shaft yekudzivirira isina chinhu; iyo motokari inopera chiso, maburi maviri epakati akaita B anovhurwa, denderedzwa rekunze rine hutsinye, uye muganho uri 1mm. Mushure mekupisa kupisa, kupisa uye kuumbwa, uyezve kutendeuka kwakanaka, kusiya muganho we 0.2mm yekukuya. Pisazve pamusoro pemoto wakaputsika kusvika pakuoma kweHRC50, wobva waikuya necylindrical grinder sezvakaratidzwa mumufananidzo uri pasi apa. Iko kurongeka kunosangana nezvinodiwa uye ichashandiswa mushure mekupedzwa.

(2) Kuti upedze kugadziridzwa kweiyo workpiece panguva imwe chete, iyo isina chinhu inochengeta iyo yekumanikidza chinzvimbo uye yekucheka margin.

(3) Kutanga, kupisa-kubata ma blanks, kudzima uye kudziya, kuomarara kuri HRC28-30 (kuoma kweiyo gadziriso renji).

(4) Chishandiso chekushandura chinotora C620. Kutanga, isa nzvimbo yepamberi mukati meiyo spindle cone uye gadzirisa. Kuti udzivise kushanduka kweiyo workpiece kana uchisunga iyo yakatetepa-yakavezwa sleeve, yakavhurika-loop gobvu sleeve inowedzerwa, sezvakaratidzwa mumufananidzo uri pazasi.

Kuti uchengetedze kugadzirwa kwakawanda, iyo yekunze yekupedzisira yeganda rakatetepa-yakakomberedzwa inogadziriswa kuita saizi d, mutongi we t ndiyo axial clamping chinzvimbo, uye yakatetepa-yakakomberedzwa casing inomanikidzwa kuvandudza kunaka kwegomba remukati. yemotokari uye chengetedza saizi. Tichifunga kuti kupisa kwekucheka kunogadzirwa, ukuru hwekuwedzera kweworkpiece yakaoma kubata. Izvo zvinodikanwa kudira yakakwana yekucheka mvura kuti uderedze deformation yekupisa kweiyo workpiece.

(5) Batanidza workpiece zvakasimba neatomatiki inoisa shaya nhatu chuck, shandura kumagumo chiso, uye rough shandura denderedzwa remukati. Siya muganho we 0.1-0.2mm yekutenderera kwakanaka, uye woitsiva neyakatsetseka yekuchinjisa chishandiso kugadzirisa muganho wekucheka kusvika shaft yekurinda yasangana nezvinodiwa zvekunyanya kukwana uye roughness. Bvisa buri remukati rinotenderedza mudziyo, isa shaft yekurinda nechekumberi, shandisa tailstock centre kusungirira zvinoenderana nehurefu hunodiwa, chinja chekunze chekutenderedza chishandiso kuti chikoshese denderedzwa rekunze, wozopedzisa kutendeukira kune zvinodiwa pakudhirowa. Mushure mokupfuura kuongorora, shandisa banga rekucheka kuti ucheke urefu maererano nehukuru hunodiwa. Kuti uite kuti kucheka kutsetseka kana workpiece yakabviswa, iyo yekucheka inofanira kurodzwa kuti iite chiso chekupedzisira che workpiece chinotapira; chikamu chiduku chegomba rekuchengetedza chinofanira kuderedzwa kuderedza gomba rakasiiwa nekucheka, uye shaft yekurinda ndeyekuderedza deformation ye workpiece, kudzivirira kudengenyeka, uye pakucheka Chikonzero chekudonha uye kuputika.

Batanidza kuchinyorwa ichi: Matekiniki eCNC Kutendeutsa kune Zvikamu-zvakatetepa-madziro

Dzokorora Chirevo: Kana pasina mirairo yakakosha, zvese zvinyorwa zviri pasaiti ino ndezvepakutanga. Ndokumbira utaridze kwakabva kudhindazve: https://www.cncmachiningptj.com

PTJ® igadziri yakasarudzika inopa huwandu hwakazara hwemabhawa emhangura, zvikamu zvendarira uye zvikamu zvemhangura. Maitiro ekugadzira akajairwa anosanganisira kuvhara, embossing, coppersmithing, waya edm masevhisi, kupinza, kuumba nekukotama, kushungurudza, kupisa forging nekutsikirira, kuboora nekurovera, kupeta shinda nekugera, kuveura; akawanda spindle Machining, extrusion uye kuumba simbi uye kutsika. Zvishandiso zvinosanganisira mabara emabhazi, maconductor emagetsi, coaxial tambo, waveguides, transistor components, microwave tubes, blank mold tubes, uye upfu hwesimbi extrusion matangi.

PTJ® igadziri yakasarudzika inopa huwandu hwakazara hwemabhawa emhangura, zvikamu zvendarira uye zvikamu zvemhangura. Maitiro ekugadzira akajairwa anosanganisira kuvhara, embossing, coppersmithing, waya edm masevhisi, kupinza, kuumba nekukotama, kushungurudza, kupisa forging nekutsikirira, kuboora nekurovera, kupeta shinda nekugera, kuveura; akawanda spindle Machining, extrusion uye kuumba simbi uye kutsika. Zvishandiso zvinosanganisira mabara emabhazi, maconductor emagetsi, coaxial tambo, waveguides, transistor components, microwave tubes, blank mold tubes, uye upfu hwesimbi extrusion matangi.

Tiudze zvishoma nezvebhajeti repurojekiti yako uye inotarisirwa nguva yekuendesa. Ticharonga newe kuti tikupe masevhisi anodhura zvakanyanya kuti akubatsire kusvika pachinangwa chako, Unogamuchirwa kutibata isu zvakananga ( sales@pintejin.com ).

- 5 Sekaiichi machine

- Cnc Kugaya

- Cnc Kutendeuka

- Machining Maindasitiri

- Machining Maitiro

- Surface Kurapa

- Simbi yekushandisa

- Mapepa epurasitiki

- Upfu hweMetallurgy Mould

- Die Casting

- Zvikamu Garari

- Auto Metal Zvikamu

- Machinery Parts

- Akatungamira Heatsink

- Kuvaka Zvikamu

- Sravana Sameeralu Serial XNUMXth Mobile Parts

- Zvikamu Zvekurapa

- Zvikamu Zvemagetsi

- Zvichienderana machine

- Bicycle Parts

- Aluminum machine

- Titanium Kubata

- Stainless Simbi machine

- Mhangura machine

- Brass machine

- Super chiwanikwa machine

- Peek Kugadzira

- UHMW machine

- Sanganisa Machining

- PA6 Kugadzira

- PPS machine

- Teflon Kugadzira

- Inconel machine

- Danho Simbi machine

- Zvimwe Zvinyorwa