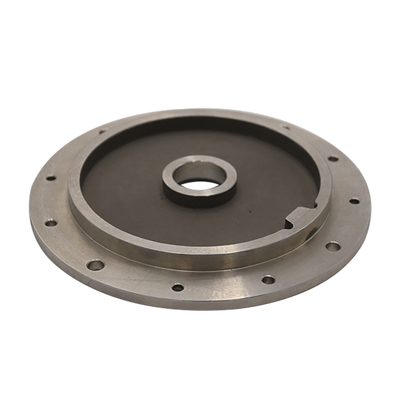

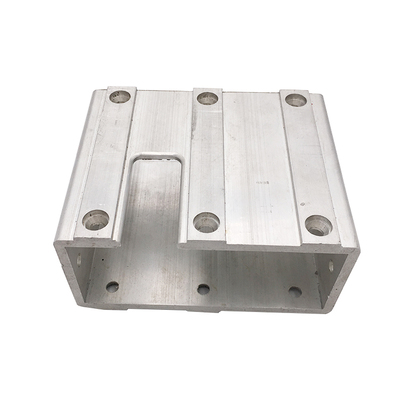

Tsvagiridzo yeKiyi Tekinoroji yeCCC Machining Maitiro eGuru Akaomarara Maumbirwo eA ndege

CNC Machining Maitiro eakakura Akaomarara Maumbirwo eA ndege

| Mukuvandudzwa kwetekinoroji yendege, izvo zvinodiwa zvehukuru-hwakakura, hwakabatanidzwa, hutete-hwakakomberedzwa, uye chaiwo ndege mamiriro ehurongwa akakurumbira kwazvo. Saizi inowedzera asi kushivirira kwakapetwa kaviri, ukobvu hwemadziro hunodzikira, asi mbabvu dzinowedzera, uye iko kwechokwadi kunowedzera. Panguva imwecheteyo, iyo indekisi yekuregedza uremu inowedzerwa, uye kuwanda kwemaumbirwo echinhu chimwe chete chechimiro chakabatanidzwa, izvo zvinotungamira kuchimiro chakasimba uye kurongeka kwenzvimbo. Hupenyu hwakareba uye huremu huremu hunoda kuti iko kusanzwisisika kwepamusoro kwekugadziriswa kunowanzo gadziridzwa ne 1-2 mazinga. Sezvo ese maumbirwo e ndege ari 100% CNC yakagadziriswa, mhando yekugadzirisa iri Kupokana nekugadzirisa kushanda kwakakurumbira. |

Munguva yekuvandudzwa uye kugadzirwa kwendege, NC machining inotarisana nematambudziko makuru-kukuvara kwemachining, kusagadzikana kwemachining, uye kushanduka kwemuchina. Kubva 2007, PTJ Shop, nerutsigiro rwemapurojekiti akasiyana siyana muindasitiri yendege, yakabudirira kugadzirisa matambudziko ataurwa pamusoro.

Izvo zvakakosha zvikonzero zvekugadzira machining kukuvara, kusagadzikana uye deformation zvinouya kubva kune kwakasimba kudyidzana kwe "muchina chishandiso-chishandiso-chekushandira" maitiro maitiro muNC. machine kwacho. Dzidziso dzechinyakare uye nzira dzakanangana neruzivo uye chinhu chimwe hachigadzirise matambudziko ari pamusoro.

Pfungwa yakajairika ndeyekugadzirisa dambudziko. Kubudikidza modelling, ongorora iyo yechimakanika hunhu hwe "kuzadza kwazvo → kukuvara", "chatter → kugadzikana" uye "kushushikana → deformation". Kubva pane fungidziro yedzidziso, "humbowo" uye "zvishandiso zvemidziyo" zvakadzingwa ". Kutanga nekubatanidzwa kweanti-cancellation, zvese zviri zviviri Hardware uye software, uye upfuure neinotevera tekinoroji yakakosha:

- 1) Kucheka simba / chafariz mutoro muyero pre-kugadzirisa kugadzirisa tekinoroji yekugadzirisa zvinhu zvakaoma uye zvimiro zvakaoma.

- 2) Yakagadzikana uye yakakwira-kumhanya yekugaya yekugadzirisa tekinoroji kune makuru matete-akavakirwa masisitimu ezvikamu;

- 3) Kufanotaura uye kudzora tekinoroji yekusara kwekushushikana uye deformation panguva yese maitiro makuru uye akaomarara masisitimu zvikamu.

PTJ Shop yakazvimiririra yakagadzirwa: NC yekuchera nguva-inosiyana yekucheka simba kufanotaura uye parameter optimization software uye Micro-lubrication chishandiso, NC yekucheka simba simulation optimization software uye passive damping vibration yekumwa mudziyo, machining deformation simulation software uye "thermal-vibration" remubatanidzwa kushushikana kuenzana chishandiso chinoshandiswa kune inoverengeka-inodzorwa machining maitiro eakakura uye akaomarara masisitimu ezve ndege, uye inogadzirisa matambudziko ekugadzirisa kusagadzikana, kukuvara uye deformation.

Kutsvagisa uye kushandiswa kweakakosha matekinoroji:

1. Kucheka simba / chafariz mutoro muyero pre-kugadzirisa kugadzirisa tekinoroji yezvinhu zvakaoma-kumushini

Dambudziko rekukanganisa mashini nderekuti iyo Laser nokuveza simba / chafariz mutoro wakakura uye unoshanduka zvakanyanya panguva ye CNC machining maitiro, ayo anokonzeresa kukuvara kwemaziso uye kupisa kwepasi kune zvinokanganisa maturusi nemabasa ekushandira, kunyanya mune yekuverenga kudzora michina yezvinhu zvakaoma-kumushini.

Iyo yechinyakare nzira yekudzivirira uye kudzora michina kukuvara ndeyekuderedza zvakanyanya huwandu hwekucheka uye kushandisa yakawanda yakawanda yekucheka fluid, iyo inonyanya kupa zvibayiro kucheka kushanda. Tatarisana nezvitsva zvekugadzirisa zvinodiwa, zvichibva pane zvine simba zvekucheka kumodhizaiza uye nekufungisisa zvipingamupinyi zvegadziriro, radial spiral layered localized circular milling method with variable spiral curves was recommended to optimize the tool path and pre-adjust the cutting parameters. Simba rekucheka rakaringana kudzivirira kuwandisa uye kukanganisa kwesimba rekucheka.

Nguva-inosiyana yekucheka simba kufembera uye paramende optimization software ye CNC machining dzendege zvikamu yakagadziriswa, uye zvirevo zvekushandisa zvakaumbwa; mhando nhatu dzequasi-yakaoma yekucheka chaiyo zvigadzirwa zvekugadzirisa zvakagadzirwa. Iyo TC4 titanium alloy super hombe furemu inogadziriswa uye kuyedzwa zvimiro zvakaoma senge mbabvu, micheto, uye maumbirwo emukati kuwana kudzikama kwekucheka kumhanya kweanopfuura 150m / min, uye kumeso kwepamusoro kwezvikamu zvakakosha kunosvika Ra1.6 ~ Ra0.8.

2.Stable yakakwira-inomhanya yekugaya yekugadzirisa tekinoroji yezvikamu zvakakura-zvakakomberedzwa

Dambudziko rekushomeka kwemashini nderekuti matete-akasimba uye akakwirisa masisitimu anokonzeresa kuti hunhu hwesimba hwehurongwa hudzikire, uye kucheka flutter kunoitika. Takatarisana nezvitsva zvekugadzirisa zvinodiwa, zvichibva pakuongorora kwemaitiro ehurongwa hwekudyidzana, "muchina wekushandisa-chishandiso-workpiece" yakasimba modhi yakagadzwa. Kubudikidza nekuyedza uye kuzivikanwa, iyo flutter kugadzikana kwesimba curve yakaverengerwa nekuenzanisa. Pasi pezvipingamupinyi zvakawanda zvehurongwa hwekuita, Optimized yekucheka parameter inopihwa kuti ibudirire-kumhanya uye kwakanyanya-kugona kucheka pasina kutaurisa, uye "kudzivirira" kusagadzikana kwemuchina.

Kubva pane iyo flutter modhi, akasiyana madamping uye vibration damping zvishandiso zvakagadzirwa uye zvakaiswa pane zvinoenderana zvikamu zveiyo machined mamiriro kana muchina chishandiso kudzvinyirira kana kudzikamisa kudengenyeka kunoitika, uye kuzadzikisa "kubviswa" kwemachining kudengenyeka.

Kuzvimiririra kwakagadzira kuzivikanwa bvunzo Hardware, X-Cut / e-Kucheka software, uye damping mudziyo, uye kumisikidza maitiro dhatabhesi inoenderana nenhamba huru yemiedzo. Semuenzaniso bvunzo dzefuselage mafuremu mundiza aluminium alloys inoratidza kuti:

Ziva chatter-yemahara kugadzikana kwekugadziriswa kweasina kusimba mitsara;

Chinyorwa chekubvisa chiyero chakawedzera neanopfuura kaviri;

Iko kusarongeka kwepamusoro kwezvikamu zvakakosha kunosvika Ra0.8 μm.

3. Kufanotaura uye kudzora tekinoroji yekusara kwekushushikana uye deformation panguva yese maitiro

Iko kushomeka kwezvinhu zvakakura uye zvakaoma zvikamu zvinonyanya kubva ku:

- 1) iko kushomeka kunokonzerwa nekusara kwekushushikana mune isina chinhu ichienderera ichisunungurwa uye kugoveredzwa panguva yekucheka maitiro;

- 2) iko kushomeka pakati pechishandiso pamwe neyekushandira (kusanganisira kuomerera) pasi pechiito chekucheka simba rehukama hwehukama.

Naizvozvo, kuumbwa kwekusara kwekushushikana mundiza dzakaumbwa zvikamu uye shanduko yeelastic deformation yebanga ndiwo musimboti wekufungidzira uye kudzora machining deformation. Kune akakura uye akaomarara ndege zvinhu, ita simulation ongororo yekusara kunetseka kubva kune isina chinhu kuenda kune chakapedzwa chigadzirwa chechimiro chechimiro, fungidzira zvakasara zvekushushikana kwekupararira kwenyika uye kugadzirisa mutemo wedhiefisiti, uye gadziridza maitiro nematanho ekudzora akasara ekumanikidza mamiriro yeiyo isina chinhu kuti uone kufungidzira kwekuzotevera CNC machine deformation. "Kudzivirirwa"; yakagadzira "thermal-vibration" inoumbwa nemutengo wakasarudzika wekushushikana, iyo inoshanda "poindi-mhango" mhando yekupisa uye yekuzungunusa mhedzisiro kune iyo workpiece kuti iite yakasarudzika kushushikana kuenzana kuti "ibvise" iyo yekushomeka pabasa.

Hunyanzvi hwese hwehunyanzvi hwekubudirira kweprojekti iyi hwasvika padanho repasi rose, uye hwasvika padanho repasirese repamberi mune yekucheka simba / yekupisa mutoro muyero pre-kugadzirisa kugadzirisa tekinoroji.

Batanidza kuchinyorwa ichi: Tsvagiridzo yeKiyi Tekinoroji yeCCC Machining Maitiro eGuru Akaomarara Maumbirwo eA ndege

Dzokorora Chirevo: Kana pasina mirairo yakakosha, zvinyorwa zvese zviri pasaiti ino ndezvepakutanga. Ndokumbira uratidze kwakabva kudhindazve: https://www.cncmachiningptj.com/, thanks!

PTJ® inopa huwandu hwakazara hweCustom Precision cnc machine china services .ISO 9001: 2015 & AS-9100 yakasimbiswa. 3, 4 uye 5-axis inokurumidza chaiyo CNC yekumisikidza masevhisi anosanganisira ekugaya, kutendeukira kune vatengi maratidziro, Anokwanisa esimbi & epurasitiki michina zvikamu ne +/- 0.005 mm shiviriro.Secondary services inosanganisira CNC uye yakajairika kukuya, kuchera,kufa kukanda,jira simbi uye kutsikaKupa prototypes, yakazara kugadzirwa inomhanya, technical technical uye yakazara kuongorora motokari, aerospace, chakuvhuvhu & yechigadziko, akatungamira mwenje,zvokurapa, bhasikoro, uye mutengi electronics maindasitiri. Pa-nguva yekuendesa.Tiudze zvishoma nezve bhajeti rako reprojekiti uye inotarisirwa nguva yekuendesa. Ticharonga pamwe newe kuti upe masevhisi anodhura kwazvo kuti ubatsire iwe kuzadzisa chinangwa chako, Gamuchirai kuti Mutaure nesu ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

PTJ® inopa huwandu hwakazara hweCustom Precision cnc machine china services .ISO 9001: 2015 & AS-9100 yakasimbiswa. 3, 4 uye 5-axis inokurumidza chaiyo CNC yekumisikidza masevhisi anosanganisira ekugaya, kutendeukira kune vatengi maratidziro, Anokwanisa esimbi & epurasitiki michina zvikamu ne +/- 0.005 mm shiviriro.Secondary services inosanganisira CNC uye yakajairika kukuya, kuchera,kufa kukanda,jira simbi uye kutsikaKupa prototypes, yakazara kugadzirwa inomhanya, technical technical uye yakazara kuongorora motokari, aerospace, chakuvhuvhu & yechigadziko, akatungamira mwenje,zvokurapa, bhasikoro, uye mutengi electronics maindasitiri. Pa-nguva yekuendesa.Tiudze zvishoma nezve bhajeti rako reprojekiti uye inotarisirwa nguva yekuendesa. Ticharonga pamwe newe kuti upe masevhisi anodhura kwazvo kuti ubatsire iwe kuzadzisa chinangwa chako, Gamuchirai kuti Mutaure nesu ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

- 5 Sekaiichi machine

- Cnc Kugaya

- Cnc Kutendeuka

- Machining Maindasitiri

- Machining Maitiro

- Surface Kurapa

- Simbi yekushandisa

- Mapepa epurasitiki

- Upfu hweMetallurgy Mould

- Die Casting

- Zvikamu Garari

- Auto Metal Zvikamu

- Machinery Parts

- Akatungamira Heatsink

- Kuvaka Zvikamu

- Sravana Sameeralu Serial XNUMXth Mobile Parts

- Zvikamu Zvekurapa

- Zvikamu Zvemagetsi

- Zvichienderana machine

- Bicycle Parts

- Aluminum machine

- Titanium Kubata

- Stainless Simbi machine

- Mhangura machine

- Brass machine

- Super chiwanikwa machine

- Peek Kugadzira

- UHMW machine

- Sanganisa Machining

- PA6 Kugadzira

- PPS machine

- Teflon Kugadzira

- Inconel machine

- Danho Simbi machine

- Zvimwe Zvinyorwa