Kuongorora kweMachining Makuru Titanium Turbine Blades Mbiri Maitiro

Kuongorora kweMachina Makuru Titanium Turbo Blades Mbiri Maitiro

|

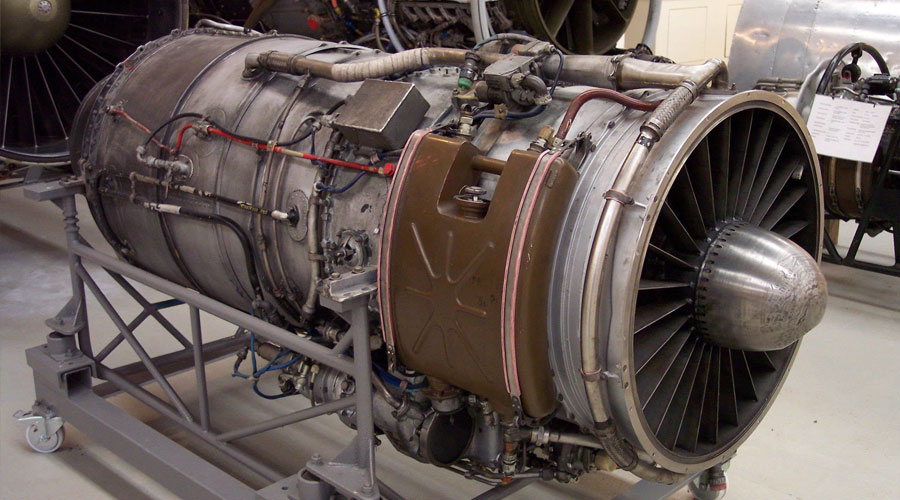

Iwo mafeni mashizha eiyo hombe yekupfuura chiyero turbofan injini yakanyanya kusvika kupfuura 500MM maererano nehurefu uye saizi. Ichi chiumbwa chakakura chinogadzira simba re centrifugal uye kushushikana kwekudengenyeka kuve kwakakura kwazvo panguva yebasa ravo, saka yavewo hombe turbo fan injini Zvakakosha zvikamu. |

Parizvino, mazhinji turbofan enjini achiri kushandisa akura zvakanyanya titanium alloy damping fan mashizha. Iyo yakatetepa uye refu dhizaini yeiri chipenga chimiro inoita kuti ive isina kusimba kuomarara muchimiro chetete-rakakomberedzwa dhizaini munzira yekubhasiketi kumashure zvakanyanya kuonekera. Iko kusarongeka kuomarara kwechimiro uye yakakura nzvimbo yenzvimbo, chimiro chechinhu chiri kunetsa kugadzirisa, chinokanganisa tsika machine kwacho, iyo inoratidzika intuitively inoratidzirwa muiyo contour saizi kururamisa uye kumira kwechokwadi kweiyo profilIyo inonetsa kuvimbisa, kugona kwebhuku kupora kwakaderera, simba rebasa rakakura, uye mhando yemashizha inokasira kupisa uye kubvisa.

Kuvapo kwematambudziko ari pamusoro apa kunogadzira ganda rekugadzira reza. Nebudiriro uye kushandiswa kwakawanda-akabatana kubatana CNC machining tekinoroji uye kutsvagisa kwekugadzira michina yeichi chipenga chimiro, matambudziko eichi chipenga machining machining akapwanywa zvishoma nezvishoma kuburikidza, uye iwo machining mhando uye kugona padanho zvasvika kune yakaenzana mamiriro.

Iyo huru tekinoroji nzira yeCCC machine yeakakura titanium chiwanikwa fan reza mbiri

Zvekugadziriswa kwemahombe titanium alloy fan blade profile, tichifunga nezve zvese zvinobatanidzwa mune zvechinyakare maitiro, ayo akashata mhedzisiro ane anotevera maficha.1. Kufurirwa kwezvinhu

- ▶ Iyo titanium alloy ine diki yakasununguka modulus, iri nyore kukonzeresa kuomesa kweye blade machining; kupfeka kwechiso chepadivi panguva yekugadzira kunowanzo wedzera simba rekucheka.

- ▶ Yakashata kudziya conductivity, ruoko-yakabwinyiswa yakaoma kukuya zviri nyore kukonzera kushushikana deformation, kupisa, uye ablation.

2. Kufuridzira kwemaitiro echando

- ▶ Iyo yakazara machining nzvimbo yeiyo mbiri yakakura, uye iko kukonzeresa kunokonzerwa nekusakara panguva yese yekuita kwechishandiso kwakakanganiswa zvakanyanya.

- ▶ Nekuda kwekukanganisa mukubata, kupora manyorero ibasa-rinoda, uye kururamisa kwemuchina kunonetsa kuvimbisa.

3. Kufurirwa kwehunhu mamiriro

Nekuda kwesimba rezvinhu uye maratidziro, zvinonetsa kuwana mugove wakaringana wemuganho, izvo zvinoguma nekucheka kushanduka kwesimba kunokonzerwa nekubviswa zvisina kufanira kwepamuganhu uye kushungurudzika deformation.4.Kufurira kwemuchina chishandiso mashandiro

- ▶ Chimiro chakakombama cheiyo chipenga chimiro, iko kucheka kutungamira kwechishandiso, iyo chaiyo yekucheka kona uye maparamendi ekucheka akasiyana, zvichikonzera shanduko mukucheka simba.

- Mamiriro ezvinhu asina kunaka ekutonhora, kutonhora kwakaringana uye hapana kutonhora kunokonzeresa kupisa kwekushushikana.

Tichifunga nezvezvinhu zvakaoma zvemashini yechipenga pamusoro peakakura titanium chiwanikwa mafeni, zvichibva pane yakazara machining zvakanakira iyo yakawanda-akabatana kubatanidza CNC michina tekinoroji, iyo mikuru nzira yekutsunga yakatemwa ndeiyi:

Kugadzirwa kweye blade tenon uye yekubatsira kumisikidza datum → iyo chipasa chimiro CNC yakashata yekugaya Machining → Stress Relief Annealing → Positioning Benchmark Kugadzirisa → Kuverenga Kudzora CNC Blade Kugaya → Mbiri Kupedza.

Iyo yakazara maitiro maitiro akagadzwa neayo ari pamusoro nzira nzira ndeyekuti: pamusoro penyika CNC yakaoma yekugaya maitiro inobvisa yakawanda yemahara, uye yekupedzisa yekugaya maitiro ine yakaringana kumahombekombe ekuparadzira; iro chipenga chimiro CNC chaiyo yekugaya maitiro inosimbisa iyo geometry yeiyo mbiri Uye chinzvimbo kunyatsoita zvinowirirana zvinowirirana neyekupedzisira kunyatso kudikanwa kweiyo chipande; kupedzisa kweye chipenga chimiro kunovimbisa kuti hunhu hwepasireji yepasirositi inosangana nezvinodiwa.

Iwo akakosha mapoinzi eCCC ekugaya eakakura titanium chiwanikwa fan reza profile

Zvinoenderana nechero tekinoroji zvinodiwa neiyo chipenga chimiro, iyo yekugaya iyo chipasa chimiro inofanirwa kuve nechokwadi chekuti geometrical chinzvimbo chakaringana cheiyo chimiro inosangana nezvinodiwa dhizaini uye ine imwe nzvimbo yepamusoro roughness. Panguva imwecheteyo, kuvandudzwa kwekushanda kwekugadzira muchina zvakare iko kwekutarisa kweprofile kugaya Shanda imwe.

Zvinoenderana nekunzwisisika kwemakemikari maitiro eakakura titanium chiwanikwa fan blade mbiri, zvinodikanwa kuti unyatso kufunga nezve simba rezvinhu zvakawanda semidziyo, maturusi, machining kumisikidza zvichingodaro. Yekugaya yemahombe titanium chiwanikwa fan fan mashizha, zvinodikanwa kusarudza shanu-akabatana machining nzvimbo. Kusarudza vakura shanu-akabatana linkage chipande machine centre ane zvose mukuru-kushanda machine kufunga uye machine zvakarurama vimbiso nezvaanogona.

Zvemuchina machining nekuchinja kwakakura mukukombama, iko kusvetuka kona basa remuchina chishandiso chokurukisa kunogona kunyatsogadziriswa kune izvo zvinodiwa zveyakaenderana ekucheka simba inoenderana neshanduko yeiyo curvature. Iyo yakanyanya-kumanikidza kutonhora sisitimu yemuchina chishandiso inoderedza zvakanyanya tembiricha yekucheka uye inodzivirira inokurumidza chishandiso kupfeka. , Saka kuti iyo michina yemuchina inogona kuwana yakanaka machining kunyatso uye yepamusoro machining mhando. Kuitira kudzivirira uye kudzikamisa torsional deformation panguva refu reza clamping uye kucheka, zvakakosha kuona kuti kutenderera mugodhis yemapfumo kumberi uye kumashure magumo emidziyo ine synchronous kutenderera basa, uye chinangwa ndechekuchinja iwo mumwe mugumo kuomerera uye kumwe kuguma kwetsika chipande machining tekinoroji.

Tight Positioning clamping nzira yekudzivirira kukotama deformation panguva yebasa clamping uye torsional deformation yeiyo chipenga chimiro munzira yekureba inokonzereswa neumwe mugumo wekutendeuka uye mumwe mugumo unotevera panguva yebasa kutenderera machining. Kuti usangane nezvinodiwa zvejecha yekumisikidza uye kuomesa, chikamu chekubatsira chinogadzika pamagumo ekupedzisira eiyo ine yakasimba nzvimbo chinzvimbo chakaringana zvinodiwa kune tenon yekumisikidza chirevo kumberi kwekupedzisira.

Mushure mekukanganisa kweiyo mbiri kwapera, kumberi uye kumashure kwejasi nekuda kwekushushikana deformation Iyo chinzvimbo chakakanganisa kukanganisa pakati peyekupedzisira mamiriro mareferenzi ichagadziriswa. Mushure mekuisa majigs epeji yekutsikisa machira pamatombo e rotary kumberi nekumashure kumagumo emuchina chishandiso, uye mushure mekuona kuti hapana kukanganisa kwekukochekera pamatombo e rotary kumberi nekumashure kumagumo kwechishandiso chemuchina, iko kuiswa kwekuisa chekumberi nekumashure zvigadziri inoonekwa uye yakagadziriswa uchishandisa yakakosha mandrel. Ita shuwa kuti iyo zvigadziri kumagumo ese ane hukama chaihwo hwehukama, kuitira kuti udzivise iyo yekuwedzera torsion kushushikana kunokonzerwa neiyo synchronous kutenderera mashandiro epamberi neshure anotenderera matemo emuchina chishandiso nekuda kwehurombo hwekukochekera chokwadi zvigadziri. Kugaya kwakashata kweye chipenga chimiro kubvisa muganho muhombe uye kusiira yunifomu yekugadzira margin yekupedzisa. Pasi peichi chirevo, mashandiro eiyi maitiro anofanirwa kuona nemazvo kugona kwemuchina. The shanu-akabatana linkage reza machine centre ane yakafara-musara machine basa.

Icho chirevo ndechekuti kana uchikuya banga, chishandiso chepakati chepakati hachina kujeka kune iyo tangent yepoindi kana iyo nzvimbo iri kukwiridzwa, asi munzira yekushandisa uye poindi kana pamusoro payo zvinokomberedzwa. Iyo yakajairwa nzira iri pane imwe kona. Mhando iyi yekugaya inoshandisa iyo yekupedzisira yekugaya chigayo, uye iyo yekugaya nzira yakafara elliptical arc. Inofananidzwa nekugaya kwemusoro webhora, yakafanana mbiri kukwirira kwepamusoro kana pamusoro inosvinwa. Panyaya yehunhu, chinhambwe pakati penzira dzakagadzirwa maturusi chakakura kwazvo. Naizvozvo, mhando iyi yemuchina ine yakakwira machining kushanda. Mukugadzira chaiko, iyo michina yemuchina nzira inofamba kubva kune mumwe mugumo kuenda kune mumwe mugumo pakureba kwebanga, ndiko kuti, nzira yekucheka yekushandisa inoshandiswa. Kubva nemaonero kunyatsoshanda, ari zononoka azvikuya nzira anewo yakakwirira machine kunyatsoshanda zvichienzaniswa longitudinal azvikuya nzira. Kugaya kwakanaka kweye chipenga chimiro ndiko kuwana yakakwira geometric uye kurongeka kwenzvimbo, uye panguva imwechete kuita kuti huwandu hwehuremu hwehukama hwuzadzise zvimwe zvinodiwa. Kuitira kudzikisira kukonzeresa kwe "rebound" kunokonzerwa nekugadziriswa kwetitanium alloy zvinhu uye kukanganisa kwechishandiso kupfeka pane chaiyo machining panguva yekugadzirisa kwemahombe-enzvimbo profiles, chishandiso chinofanirwa kuve chakapinza uye kudzivirira kureba kwenguva refu kwechishandiso. Nechikonzero ichi, kana zvichibvira, shandisa chigayo chekupedzisira kuti uite mirefu yekureba yemufananidzo. Longitudinal azvikuya anogona kushandisa maturusi akati wandei kukora reza kumashure pamusoro, shizha pamusoro, kunwa kumucheto, uye kupera chiuno, kudzivirira kusakara kunokonzerwa nemwero wakakura machining yechimwe chishandiso, uye kuburitsa nhanho chaiyo pamusoro penzvimbo blade.

Iko kusawirirana kunobatsira pakupedzisa kwekupedzisira kweprofile. Kana uchikuya rakakura titanium chiwanikwa fan rotor blade, kuitira kugadzirisa mamiriro ekucheka, matanho ese ekudzivirira chishongedzo kupfeka anodiwa. Panyaya yekusarudzwa kwemidziyo yezvishandiso uye maratidziro, iyo yakaoma yakaoma chiwanikwa chakaputirwa cylindrical bhora yekugura cutter inoshandiswa kugadzirisa iro remukati reza reza rejinga replate, yemukati chikamu chemupendero ndiro uye chimiro chekuchinja arc, shanduko mbiri kune ndiro yekumucheto 1. Nezve iyo yekudyira uye yekupedza micheto, sarudza yekuguma chigayo ine cylindrical yekuisa uye yakaoma alloy yakavharwa blade yekugadzirisa iyo hombe-nzvimbo nzvimbo chimiro pamusoro peye reza shizha hari uye blade kumashure.

Iko kusarudzwa kwemachira ekumachira emachina titanium chiwanikwa maturusi kwakakosha kwazvo. Dzivisa kushandisa zvekunamatira zvinhu zvine hukama ne titanium alloys. Parizvino, PVD yakavharwa maturusi anowanzo shandiswa mukugadzira machini titanium alloys. Iyo PVD kupfeka yakatetepa uye yakatsetseka. Kana zvabatanidzwa nesamende carbide substrate yechishandiso, ivo vanogadzirawo kusara kwekushushikana. Kushushikana uku kunobatsira kugadzirisa kusagadzikana kwechombo. PVD Inogona kusungirirwa padhuze nechombo, izvo zvinobatsira kuchengetedza unopinza wekucheka chimiro. Iyo PVD chishandiso ine yakanaka abrasion kuramba, yakatsiga makemikari zvivakwa, uye hazvisi nyore kuburitsa yakavakirwa-pamupendero. Munguva yekugadzira, inotonhorera inokwana inofanirwa kushandiswa kutonhodza chishandiso uye nekuvandudza kukanganisa kwekukwesana, sarudza zvine mutsindo zvekucheka parameter, uye nekuvandudza mhedzisiro yekucheka simba.

Hunhu hweCNC Kupedza kweakakura Titanium Fan Blade Mbiri

Nereza Profile kupedzisa ndiko kuva nechokwadi kuti Profile roughness uye waviness kusangana magadzirirwo zvinodiwa, zvinhu zvinhu mashandiro haachinji, uye geometric kukura uye nzvimbo kunyatsoshanda vakawana nokugaya havana kumboshanduka panguva machine.

Kune chaiyo machining, iko kupedzisa kweye blade mbiri kunoenderana nekubvisa iyo yasara turu mamaki pane yekugaya maitiro kuti uwane hunodiwa hukasha uye husimbe. Huwandu hwesimbi kubviswa kune rumwe rutivi rwekuumba pamusoro haufanire kuve hwakakura kupfuura 0.05MM. Parizvino, kushandiswa kweCNCB isingasviki bhandi kukuya uye kupukuta muchina maturu echipaza pamusoro kupedzisa inzira yakakura kwazvo yekushandisa machining mashandisirwo, uye kushandiswa kweCCN madhaimani kukuya vhiri kukuya muchina maturusi echipaza pamusoro kupedzisa ndeyekuedza application. Nzira.

Icho chikonzero nei idzi nzira dzekugadzira dzakasarudzwa kuti dziishandiswe ndeyekuti zvine maitiro avo. Chekutanga pane zvese, yeiyo machining nzira yeCCC hasha bhandi kukuya uye kupora maturusi emuchina, ine zvinotevera hunhu:

- ▶ Zviyo zvehasha zvebhandi rakashata rakapinza uye iko kukuya kushanda kwakakwirira, uko kwasvika nguva gumi dzekugaya uye ka10 dzese dzekugaya vhiri kukuya;

- ▶ Kukakavadzana pakati pehasha bhandi kukuya uye workpiece ishoma, kukuya kunogadzira kupisa kushoma, hasha bhandi denderedzwa rakakura, uye hasha chidimbu chine nguva yakareba yenguva yekupisa kupisa. Zviri nyore kuwana kutonhodza kwakazara kwemhepo uye kucheka fluid, izvo zvinogona kudzikisira kushanduka kweiyo workpiece Burns uye ablation;

- ▶ Iko kupfava kwebhanhire rinopwanya uye chimiro chemuviri werabha pamusoro pevhiri rebasa rinovimbisa kuti bhandi rinosemesa riri kusangana nechaishandiswa uye rine yakanaka yekumhanyisa-mukati uye kupora maitiro;

- ▶ Hasha bhandi kukuya Pane yakagadzikana hasha chishandiso saizi, nekuti hasha bhandi rakanamatira kune rebasa vhiri rekukuya, hasha chishandiso saizi ine kugadzikana kuri nani;

- ▶ Hasha bhandi kukuya haigone kugadziriswa kwenguva yakareba iine huwandu hukuru hwekubviswa, uye bhandi rine hasha rine huwandu hwese hweabrasives hushoma, uye kwenguva refu machining nekubvisa kwakakura kwakanyanya kuchakurumidza kupedza abrasives, uye zvinodikanwa kukanganisa mashini uye kutsiva rakashata bhandi.

Iwo ataurwa pamusoro maitiro ehasha bhandi kukuya inoita kuti zvive nyore kune yakakura titanium chiwanikwa fan reza pevhu kupora kuti vaone michini yekugadzira pasi pechirongwa-chinodzorwa mamiriro. Parizvino, pane nzira mbiri dzekusarudza kubva kune iyo CNC bhandi yekugaya nzira inoshandiswa pakuisa blade: imwe ndeye kushandisa six-axis CNC bhandi yekugaya nekukora muchina, uye imwe yacho kushandisa robhoti CNC bhandi kupora system. machine. Kufambisa basa kweiyo matanhatu-akabatana CNC bhandi kukuya uye kupora muchina kwakafanana neshanu-akabatana CNC machining nzvimbo panguva yekugaya.

The STRUCTURAL musiyano pakati bhandi vachikuya basa vhiri uye magumo chigayo machine anoita zvinoita zvakakodzera kuti kuchinja Profile machine kuti chipande mamiriro. Iine swing angle inoshanda mune mbiri nzira. Nhanhatu-akabatana CNC hasha bhandi vachikuya uye makorari muchina ane hunyambiri mashandiro ehuyo kukuya uye kupukuta. Iko kushandurwa kwebasa kunoenderana nekushandurwa kwemusoro wesimba muchimiro chekukuya kwakasimba uye kuyangarara kunoyangarara.

Munguva yekukorobha maitiro, iyo inogara ichimanikidza ichiyangarara mashandiro yakaitwa, kuitira kuti shanduko yekukuya kumberi kumanikidza inogona kunyatso kudzorwa neinomanikidza sensor, iyo yekugaya simba sensor, inogara ichimanikidza humburumbira uye dzimwe nzira dzekujaira mutsauko mune saizi yega yega blade profile mukati meimwe nhanho. Makorari machine pasina kuparadza kururama Profile. Paunenge uchiita kukuya kweprofile, vhiri rekubata rinoyangarara mashini rakakiiwa kubvumira kuomarara kweiyo mbiri.

Iyo yakaoma kugedza maitiro eiyo mbiri inogona kuwedzera kana kutsiva mamiriro acho kana iko kunyatso kujeka kweprofile kuri kusarongeka, uye saizi yezviyo yebhanhire rinoshatisa rinoshandiswa rinofanira kuchinjwa zvinoenderana nemucheto. Kugadzira uku kuchachinja Iyo yepakutanga ndeyenzvimbo chinzvimbo kunyatsoita, uye zvine chekuita nekugaya maitiro, kubviswa kwemahombekombe akawandisa kuchaburitsa hombe kusagadzikana deformation. Naizvozvo, hazvikurudzirwi kushandisa basa rekukuya pasi pefungidziro yekuti nzira yekugaya inokwanisa kuvimbisa kunyatso. Robhoti CNC hasha bhandi kupora nzira ndeyekuti robhoti inobata jasi uye inoita kufamba kwakakombama pasi pechirongwa kudzora kuita polishing machining pane yakagadziriswa hasha bhandi muchina. Iyo machining inoshandisa reverse engineering technology. Asati machina, robhoti rinobata banga re tenon chikamu kuti riongorore chimiro cheiyo chipenga chimiro, uyezve iyo data machining mashandiro inogadzira iyo machining yekudzivirira chirongwa, uye pakupedzisira inoziva kukwesha kweiyo chipasa pasi pechirongwa kudzora. Parizvino, nekuda kwekukamurwa kwekufamba nemazvo, iyo robhoti hasha bhandi yekugedza nzira inowanzo shandiswa senzira yekuratidzira kupora. The vachikuya nzira CNC nedhaimani vachikuya mavhiri ndezveiye chaiwo akaomarara uye akaomarara kukuya. Iyo muchina chishandiso kufamba mashandiro anoshandiswa zvakangofanana zvakafanana neshanu-akabatana kubatanidza chisvo hwokugayagisa machine centre. Yekucheka chishandiso chinoshandiswa kushandura yakatwasuka yekugaya cutter kune iyo yakavharidzirwa nedhaimani hupfu. Cylindrical kukuya vhiri. Munguva yekukuya, yakafara-mutsara machining tekinoroji inoshandiswa. Iyi mhando yemachining nzira yakaoma uye inoomarara kukuya. Nekuti iro vhiri redhiimendi pacharo rine mweya wakashata unokwenenzverwa, haigone kuzadzikisa kupisa kwekupisa nekuchengetedza uye nekutsinhana iyo inotonhorera svikiro, saka haina kukodzera kukuya pamusoro pechikamu nemari yakawanda yekubvisa, uye kunyangwe Icho chinhu maitiro anobvisa muganhu mudiki, uye zvakare zvakareraka kupisa kukuya kweye banga pamusoro peiyo titanium chiwanikwa zvinhu.

Naizvozvo, kana uchishandisa nzira iyi kugadzirisa blade pamusoro peiyo titanium alloy blade, zvinodikanwa kuti uwane iyo yakakodzera kwazvo yekucheka parameter uye muchina chishandiso kutonhora Iyo nzira inofanira kuve inoshanda kwazvo. Uye zvakare, iyo yakaoma uye yakaomarara kukuya zvimiro zvedhaimani vhiri riri pamusoro pechiso zvakare rine imwe "kumucheto" kweanocheka. Kunyangwe ichikwanisa kuvandudzwa nekugadzirisa chirongwa ichi kune yakatarwa nevhiri rinokuya, harigone kubviswa zvachose. Iko kuneta kwekuneta kuita hakufadzi, saka matanho ekuwedzera anofanirwa kutorwa kubvisa pamusoro "makomo". Zvinogona zvakare kuve zvakafanira kushandisa CNC hasha bhandi kukuya uye kupora maturu emuchina ekuwedzera michina iri pasi pechirongwa chinoenderana. Uye zvakare, iko kushandiswa kwemahara emahara zvimiro zvejecha nyoro kufuridza nzira yekuwedzera michina inofanira zvakare kuve nzira inogoneka. Nekuda kwezvinhu zvataurwa pamusoro apa zve CNC mangoda ekugaya vhiri yekugaya nzira, mashandisiro ayo emuchina achiri muchikamu chekutsvagisa. Parizvino, iyo CNC ine hasha bhandi yekugeda uye kupukuta muchina chishandiso nzira iri kuve inova nzira yakakodzera kwazvo yekukorobha kwemahombe mapaundi profiles nekuda kwezvakawanda zvayakanakira. Yayo nzwisisika mukana ndeyekuti inogona kushandiswa kune yakaoma kukuya uye kunyorova kukuya. Inogona zvakare kuita yekupedzisira-yakadzika tembiricha kukuya pasi pe CO2 kutonhora, izvo zvinobatsira kwazvo kudzivirira kutsva uye ablation yeakakura titanium chiwanikwa zvinhu chipande chipanje chimiro kupora.

Iko kushandiswa kweCNC kukuya uye kupukuta maturusi emuchina kwachinja hukuru-hukuru hwemanyorerwo echinyorwa emahombekombe mahombe, ayo akaita chinzvimbo chakakosha mukuvandudza kugadzirwa kwemashizha makuru. Kubudirira uye kushandiswa multi-akabatana linkage machine michina kwave nani chaizvo kururama uye yepamusoro vimbiso kugona anokosha machine machine hombe injini feni chipande Profile machine, uye kubudirirawo zvinogutsa zvinoguma machine machine kunyatsoshanda. Ini ndinotenda kuti neyakaenderera Kuramba kutsvagisa uye kugadzirisa kwemidziyo tekinoroji, hombe-chiyero fan reza chipenga machining tekinoroji inokura munzira yekugadzira michina uye otomatiki.

Batanidza kuchinyorwa ichi: Kuongorora kweMachining Makuru Titanium Turbine Blades Mbiri Maitiro

Dzokorora Chirevo: Kana pasina mirairo yakakosha, zvinyorwa zvese zviri pasaiti ino ndezvepakutanga. Ndokumbira uratidze kwakabva kudhindazve: https://www.cncmachiningptj.com/, thanks!

PTJ® inopa huwandu hwakazara hweCustom Precision cnc machine china services .ISO 9001: 2015 & AS-9100 yakasimbiswa. 3, 4 uye 5-axis inokurumidza chaiyo CNC yekumisikidza masevhisi anosanganisira ekugaya, kutendeukira kune vatengi maratidziro, Anokwanisa esimbi & epurasitiki michina zvikamu ne +/- 0.005 mm shiviriro.Secondary services inosanganisira CNC uye yakajairika kukuya, kuchera,kufa kukanda,jira simbi uye kutsikaKupa prototypes, yakazara kugadzirwa inomhanya, technical technical uye yakazara kuongorora motokari, aerospace, chakuvhuvhu & yechigadziko, akatungamira mwenje,zvokurapa, bhasikoro, uye mutengi electronics maindasitiri. Pa-nguva yekuendesa.Tiudze zvishoma nezve bhajeti rako reprojekiti uye inotarisirwa nguva yekuendesa. Ticharonga pamwe newe kuti upe masevhisi anodhura kwazvo kuti ubatsire iwe kuzadzisa chinangwa chako, Gamuchirai kuti Mutaure nesu ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

PTJ® inopa huwandu hwakazara hweCustom Precision cnc machine china services .ISO 9001: 2015 & AS-9100 yakasimbiswa. 3, 4 uye 5-axis inokurumidza chaiyo CNC yekumisikidza masevhisi anosanganisira ekugaya, kutendeukira kune vatengi maratidziro, Anokwanisa esimbi & epurasitiki michina zvikamu ne +/- 0.005 mm shiviriro.Secondary services inosanganisira CNC uye yakajairika kukuya, kuchera,kufa kukanda,jira simbi uye kutsikaKupa prototypes, yakazara kugadzirwa inomhanya, technical technical uye yakazara kuongorora motokari, aerospace, chakuvhuvhu & yechigadziko, akatungamira mwenje,zvokurapa, bhasikoro, uye mutengi electronics maindasitiri. Pa-nguva yekuendesa.Tiudze zvishoma nezve bhajeti rako reprojekiti uye inotarisirwa nguva yekuendesa. Ticharonga pamwe newe kuti upe masevhisi anodhura kwazvo kuti ubatsire iwe kuzadzisa chinangwa chako, Gamuchirai kuti Mutaure nesu ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

- 5 Sekaiichi machine

- Cnc Kugaya

- Cnc Kutendeuka

- Machining Maindasitiri

- Machining Maitiro

- Surface Kurapa

- Simbi yekushandisa

- Mapepa epurasitiki

- Upfu hweMetallurgy Mould

- Die Casting

- Zvikamu Garari

- Auto Metal Zvikamu

- Machinery Parts

- Akatungamira Heatsink

- Kuvaka Zvikamu

- Sravana Sameeralu Serial XNUMXth Mobile Parts

- Zvikamu Zvekurapa

- Zvikamu Zvemagetsi

- Zvichienderana machine

- Bicycle Parts

- Aluminum machine

- Titanium Kubata

- Stainless Simbi machine

- Mhangura machine

- Brass machine

- Super chiwanikwa machine

- Peek Kugadzira

- UHMW machine

- Sanganisa Machining

- PA6 Kugadzira

- PPS machine

- Teflon Kugadzira

- Inconel machine

- Danho Simbi machine

- Zvimwe Zvinyorwa