Chii chinonzi Inconel 625

Tsananguro yeInconel 625

|

Inconel625 mhinduro yakasimba inosimbisa nickel-yakaremara superalloy ine molybdenum uye niobium sezvinhu zvikuru zvinosimbisa. Iyo ine yakanakisa ngura kuramba uye oxidation kuita. Iyo ine yakanaka tensile zvivakwa uye kuneta zvivakwa kubva pasi tembiricha kusvika 980 ℃, uye ine munyu-unodzivirira Stress ngura munzvimbo ine foggy mhepo. |

Naizvozvo, inogona kushandiswa zvakanyanya kugadzira zvikamu zveinjini, muchadenga nzvimbo uye zvigadzirwa zvemakemikari. Iyo alloy ine yakanaka yekugadzirisa uye yekushisa mashandiro, uye inogona kupa akasiyana maplate, mabara, pombi, waya, mitsetse uye forgings.

Chiwanikwa 625 chinhu ngura nemishonga, oxidation nemishonga nickel anotsanangura chiwanikwa. Iyo yakanakisa simba uye kuomarara kwe625 chiwanikwa mune yakaderera tembiricha-1093 ° C tembiricha renji inotorwa kubva kune yakasimba mhinduro mhedzisiro yeanodzora simbi colium uye molybdenum mune iyo nickel-chromium matrix. Iyo yakanakisa kuneta simba uye kupokana nekushushikana nemarara kutsemuka kwe625 chiwanikwa kubatsirwa kubva kune chloride ion mune izvo zvinhu.

Inconel 625 kunyorera

625 chiwanikwa chinonyanya kushandiswa kugadzira kupisa nhovo, turbine injini mhepo ducts, yemukati kupisa machubhu, mafuta jekiseni matanda, kemikari indasitiri michina uye akakosha emvura yegungwa mafomu.

Inconel 625 ngura kuramba

625 alloy inogona kumira munzvimbo dzakasiyana dzinokanganisa. Mune alkaline mhinduro, gungwa mvura, mvura nyowani, kwazvakarerekera munyu nemhepo, izvo zvinhu zvine zvishoma ngura. Nickel uye chromium zvinoriumba zvinopa antioxidant kugona. Nickel uye molybdenum zvinopa kurwisa kuora neasina-oxidizing magasi. Molybdenum inogona kunyatso kudzivirira pitting uye crevice ngura. Kupokana nekloride kunetseka ngura kutsemuka kunonyanya kuve kwakakurumbira. Panopisa tembiricha, 625 chiwanikwa hachiwanzo kubatika kana kusanganisa.

Physical properties

Kuwanda kwevanhu: 8.44

Avhareji chaiyo kupisa: 0.098 btu / lb / ° F

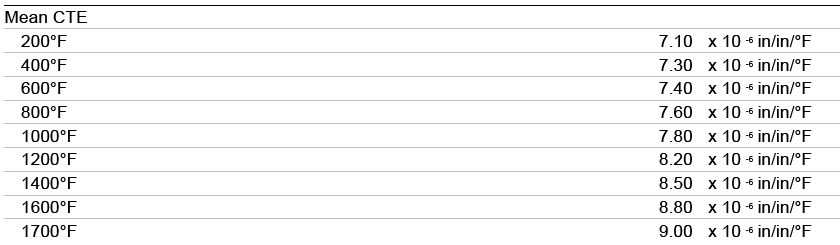

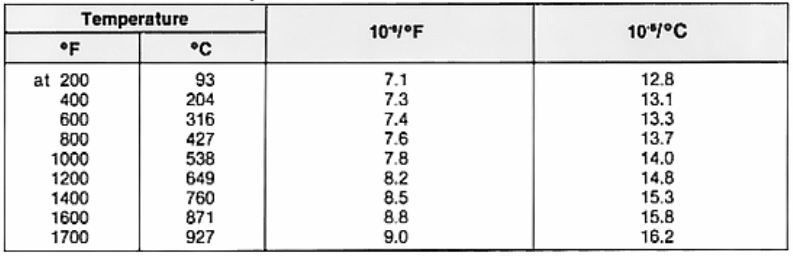

Avhareji yekuwedzera kwekuwedzera kwekuwedzera

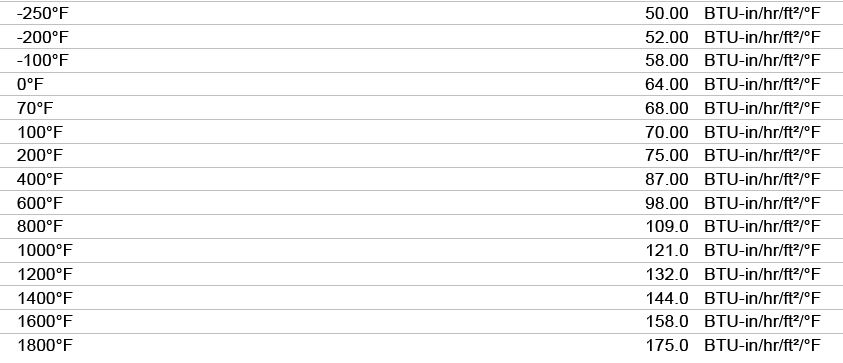

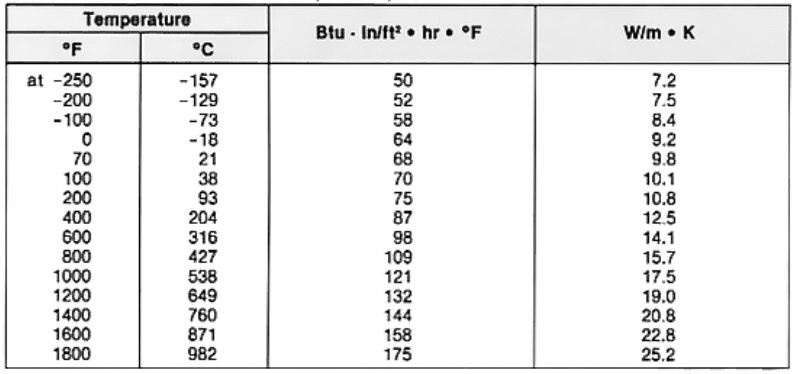

Inconel 625 Thermal conductivity

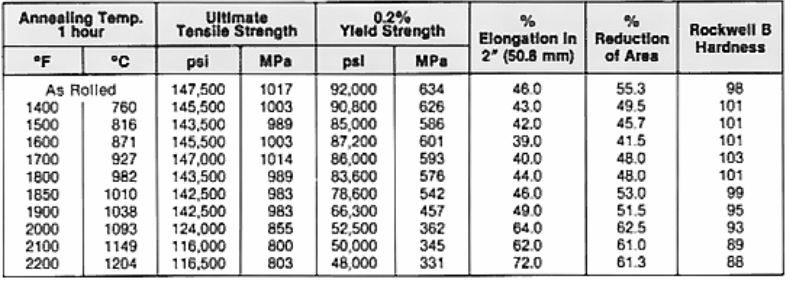

Inconel 625 zvinhu zvinopisa zvinopiswa pa1149 ° C kwe1 awa

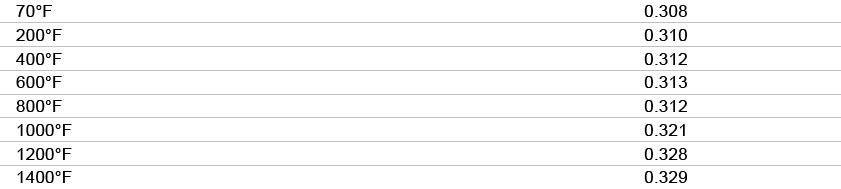

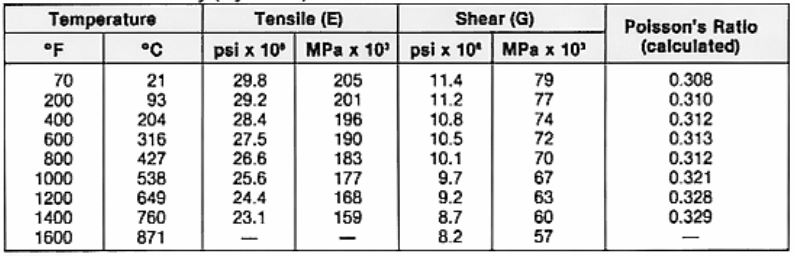

Inconel 625 Poisson chiyero

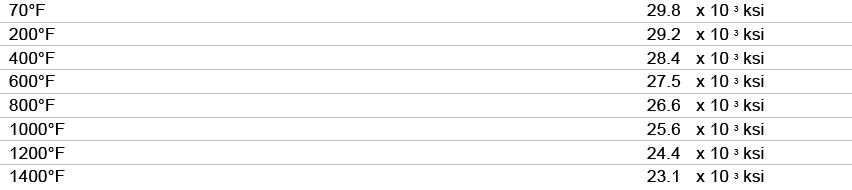

Modulus yekusununguka (E)

Modulus yekusimba (simba)

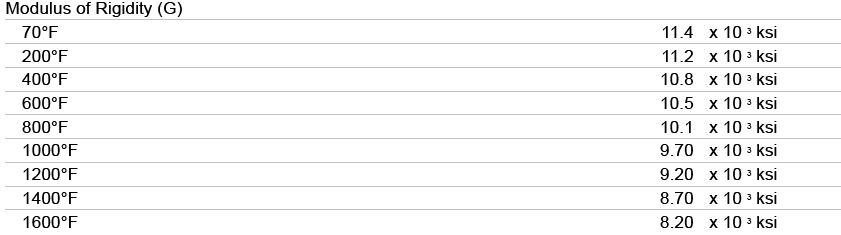

Rigidity modulus (G)

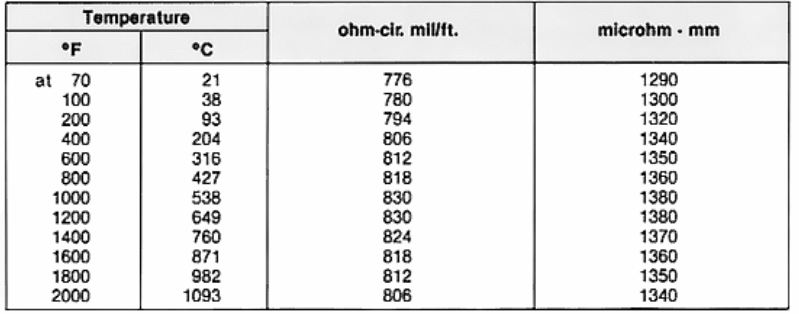

Inconel 625 Kuramba

Kupisa kwezvinhu kwakarapwa pa1149 ° C kwe1 awa

Tembiricha yeCurie: < -320 ° F

Kunyorera nzvimbo: 2350-2460 ° F

Magnetic

Magnetic flux (200 Oe): 1.0006Mu

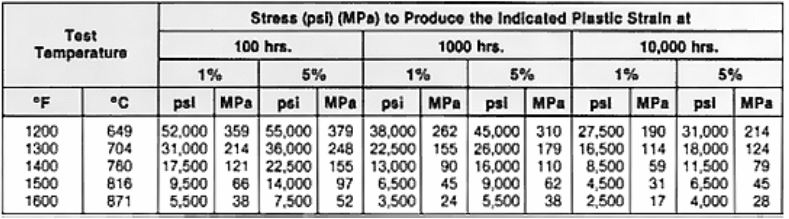

Inconel 625 Creep performance

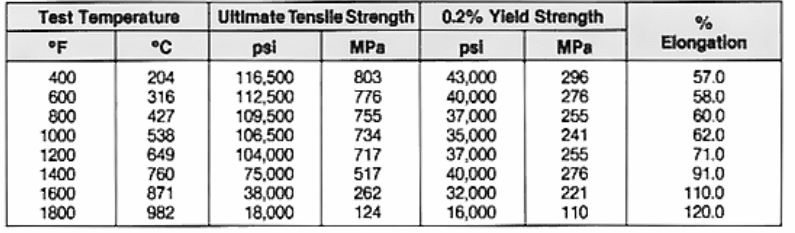

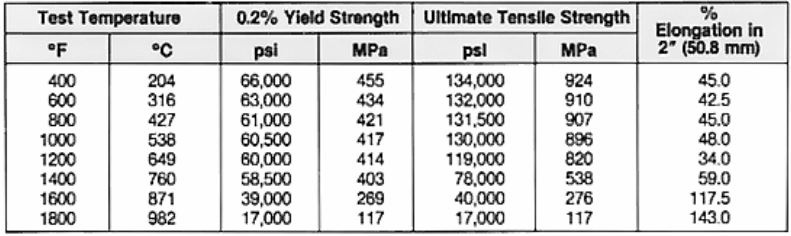

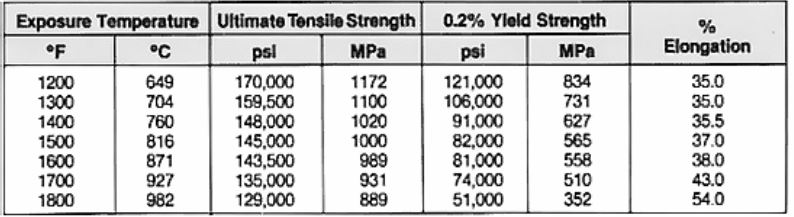

Tensile zvivakwa pakukwirira tembiricha

Mhedzisiro yekuwedzera tembiricha

Tensile zvivakwa pakukwirira tembiricha

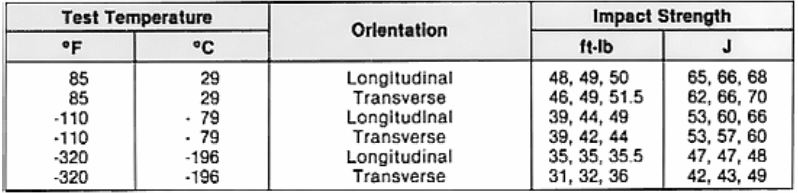

Impact bvunzo-keyhole notch

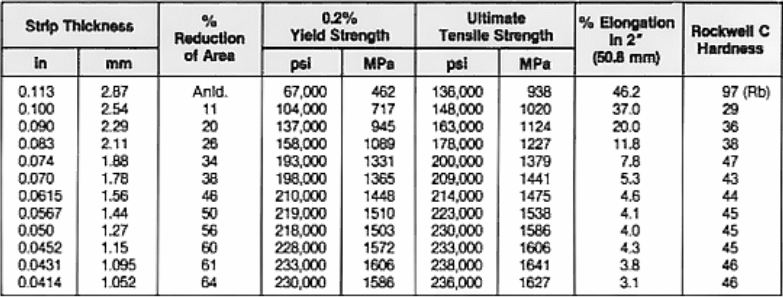

Tensile zvivakwa pakamuri tembiricha

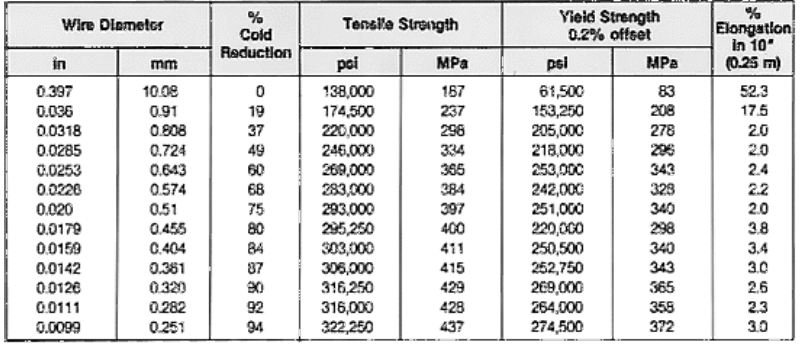

Tensile simba pakamuri tembiricha

Kupisa kupisa, yakaderera mhinduro annealing, maawa zana pane tembiricha yakanyorwa mune tafura pazasi

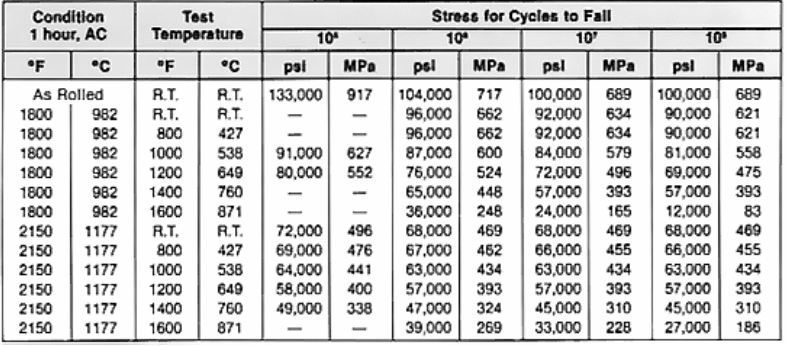

Inotenderera danda kuneta simba

Heat kurapwa

Pane nzira nhatu dzekutanga dzokurapa kupisa kwe625 alloy:

1. Mhinduro yepamusoro inovhara: 1093-1204 ° C, kudzima mweya kana kudzima nekukurumidza

2. Yakadzika mhinduro inovhara: 927-1038 ° C, kudzima mweya kana kudzima nekukurumidza

3. Kunetseka kwepfungwa: 899 ° C, kudzima mweya

Iyo yekupisa nguva yekurapa inoenderana nehuwandu hwezvinhu uye ukobvu hwechikamu chemuchinjikwa. Iyo yekupisa nguva yekurapa yemaitiro 1 ne2 inowanzoita 1 / 2-1 awa, uye iyo yekupisa nguva yekurapa nzira 3 maawa 1-4.

Kana tembiricha iri kushanda iri pamusoro pe816 ° C uye kuramba kwekukwira kunonyanya kukosha, Nzira 1 inowanzo shandiswa kugadzirisa zvinhu. Zvigayo zvesimbi zvinoshandisa zvakare yakanyanya mhinduro annealing kugadzira izvo zvinhu zvakapfava uye nyore kutonhora-kutenderera kana kutonhora-dhonza.

Maitiro 2 ndiyo inonyanya kushandiswa kupisa nzira yekurapa. 1038 ° C inogona optimize iyo yakazara kuita kwesimba tensile uye kutsemura simba. Panguva imwecheteyo, iyo ductility uye kuomarara pasi peyepasi tembiricha nharaunda zvakare yakanaka kwazvo.

Kana tembiricha iri kushanda iri pazasi pe649 ° C, kana izvo zvinodikanwa pakuneta kwekuneta, simba risingachinjiki, simba rekupa uye kuomarara kwechinhu chakakwira, Nzira 3 inokurudzirwa kurapwa kwekupisa. Iyo yakarapwa zvinhu zvine yakanaka kwazvo ductility uye kuomarara mune yakaderera tembiricha nharaunda. Kana zviyo zvakawandisa zvichidikanwa, izvo zvinhu zvinowana simba rakanaka rekuneta, simba rakasimba uye nekupa simba mune zvakatipoteredza pazasi pe816 ° C. Dzimwe nguva nzira 3 inogona zvakare kushandiswa.

Thermal kugadzira

Iyo yakanyanya tembiricha tembiricha yekupisa kugadzira ndeye 1149 ° C. Chenjera kuti urege kuunganidzwa kwekupesana kupisa kunogona kukonzeresa kupisa kupisa kupfuura 1149 ° C. Alloy 625 inozove yakaoma zvakanyanya pasi pe1010 ° C. Kana iri pazasi peichi tembiricha, iyo workpiece inoda kudzokororwa. Zvinokurudzirwa kuita yunifomu yekuchengetedza kudzivirira kusanganiswa kwekristaro chimiro. Iyo yakapera yekugadzira chiyero ingangoita 15-20%.

Kutonhora Kuita

625 alloy inokodzera nzira dzakasiyana siyana dzekushanda dzinotonhora. Mushure mekushanda kunotonhora, iyo yekushandira inoomarara uye inogona kudzoreredzwa kune yayo ductility ne annealing.

Iko kukanganisa kwebasa rinotonhora

Usati watonhora kushanda, tambo yacho inosungirirwa pa1019 ° C.

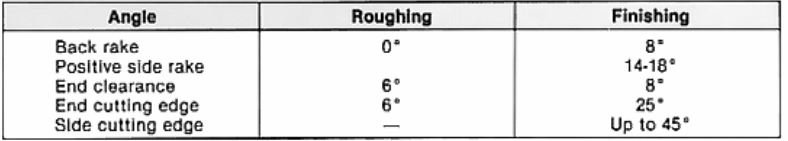

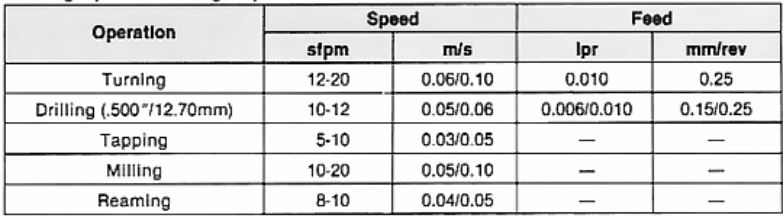

Mashandiro emuchina

Inowanzo kukurudzirwa kushandisa yakaderera kucheka kumhanya, dense maturusi, zvinorema zvishandiso, yakakwana inotonhorera, uye yekumanikidza chikafu kugadzirisa 625 alloy.

Kutendeuka kweakakwira-kumhanya ekucheka maturusi

Iyo yakanyanya tembiricha tembiricha yekupisa kugadzira ndeye 1149 ° C. Chenjera kuti urege kuunganidzwa kwekupesana kupisa kunogona kukonzeresa kupisa kupisa kupfuura 1149 ° C. Alloy 625 inozove yakaoma zvakanyanya pasi pe1010 ° C. Kana iri pazasi peichi tembiricha, iyo workpiece inoda kudzokororwa. Zvinokurudzirwa kuita yunifomu yekuchengetedza kudzivirira kusanganiswa kwekristaro chimiro. Iyo yakapera yekugadzira chiyero ingangoita 15-20%.

Yakakwira-inomhanya simbi yekucheka kumhanya

Iyo kona ye carbide chishandiso idiki pane yeiyo HSS chishandiso, uye yekumhanyisa kumhanyisa inokurumidza.

Inokurudzirwa kushandisa sarufa-based cutting fluid. Mushure mekugadzirisa, zvinodikanwa kuti unyatsochenesa iyo yekushandira kuti urege kuunza zvakasvibisa zvepasirese mune inotevera kupisa kurapwa maitiro.

Welding

Welding gasi inogona kushandiswa pakutema, tungsten electrode kana unopisa simbi electrode. Hapana post-weld yekupisa kurapwa inodiwa kuchengetedza ngura kuramba. Asati Welding, nyatsoteerera kuchenesa nomoto pamusoro uye kunangiswa ari nomoto musono. Iyo gobvu yekutenderera nharaunda inotora U-yakaumbwa nzira yekutenderera.

Batanidza kuchinyorwa ichi: Chii chinonzi Inconel 625

Dzokorora Chirevo: Kana pasina mirairo yakakosha, zvinyorwa zvese zviri pasaiti ino ndezvepakutanga. Ndokumbira uratidze kwakabva kudhindazve: https://www.cncmachiningptj.com/, thanks!

PTJ CNC shopu inogadzira zvikamu zvine yakanakisa michina zvivakwa, kurongeka uye kudzokorora kubva kusimbi nepurasitiki. 5 akabatana CNC azvikuya iripo.Kugadzira yakakwira-tembiricha chiwanikwa range inclouding inconel machine,monel machine,Kugadziriswa kweGeek Ascology,Carp 49 machine,Hastelloy machine,Nitronic-60 machine,Hymu 80 kugadzira,Danho Simbi machine, nezvimwe.,. Yakanakira kunyorera nzvimbo.CNC machining inogadzira zvikamu zvine yakanakisa mehendi zvivakwa, kurongeka uye kudzokorora kubva pasimbi nepurasitiki. 3-axis & 5-axis CNC yekugaya iripo.Ticharonga pamwe newe kuti tipe yakanyanya-isingadhuri masevhisi ekukubatsira iwe kuti usvike kune chako chinangwa, Gamuchirai Kwatiri isu ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

PTJ CNC shopu inogadzira zvikamu zvine yakanakisa michina zvivakwa, kurongeka uye kudzokorora kubva kusimbi nepurasitiki. 5 akabatana CNC azvikuya iripo.Kugadzira yakakwira-tembiricha chiwanikwa range inclouding inconel machine,monel machine,Kugadziriswa kweGeek Ascology,Carp 49 machine,Hastelloy machine,Nitronic-60 machine,Hymu 80 kugadzira,Danho Simbi machine, nezvimwe.,. Yakanakira kunyorera nzvimbo.CNC machining inogadzira zvikamu zvine yakanakisa mehendi zvivakwa, kurongeka uye kudzokorora kubva pasimbi nepurasitiki. 3-axis & 5-axis CNC yekugaya iripo.Ticharonga pamwe newe kuti tipe yakanyanya-isingadhuri masevhisi ekukubatsira iwe kuti usvike kune chako chinangwa, Gamuchirai Kwatiri isu ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

- 5 Sekaiichi machine

- Cnc Kugaya

- Cnc Kutendeuka

- Machining Maindasitiri

- Machining Maitiro

- Surface Kurapa

- Simbi yekushandisa

- Mapepa epurasitiki

- Upfu hweMetallurgy Mould

- Die Casting

- Zvikamu Garari

- Auto Metal Zvikamu

- Machinery Parts

- Akatungamira Heatsink

- Kuvaka Zvikamu

- Sravana Sameeralu Serial XNUMXth Mobile Parts

- Zvikamu Zvekurapa

- Zvikamu Zvemagetsi

- Zvichienderana machine

- Bicycle Parts

- Aluminum machine

- Titanium Kubata

- Stainless Simbi machine

- Mhangura machine

- Brass machine

- Super chiwanikwa machine

- Peek Kugadzira

- UHMW machine

- Sanganisa Machining

- PA6 Kugadzira

- PPS machine

- Teflon Kugadzira

- Inconel machine

- Danho Simbi machine

- Zvimwe Zvinyorwa