Inoshanda Machining YeTitanium Alloy Ndege Zvikamu

Inoshanda Machining YeTitanium Alloy Ndege Zvikamu

|

Titanium chiwanikwa chine zvakwakanakira zvekudzikira kwesimba uye ngura kuramba, uye inoshandiswa zvakanyanya mukuvakwa kwemitumbi yendege, asi inowanzo deformation panguva yecnc machining, uye iko kurongeka kwemachira kunonetsa kuvimbisa. Naizvozvo, zvinodikanwa kushandisa tekinoroji yemazuva ano uye zvivakwa zvakakwana kugadzira nzira dzinoshanda dzekugadzirisa, uye pakupedzisira kuvandudza hunyanzvi hwese hwekushandisa uye mhando kuburikidza CNC machining midziyo. Kuongorora kwakadzama kwakasanganiswa ne titanium chiwanikwa machine nzira dzakanangana nekuvandudza mashandiro ekugadzirisa zvikamu zvine hukama |

Semhando yepamusoro-yesimba yezvinhu zvikamu, titanium alloy zvikamu zvine yakanyanya kukwirira kunyorera kukosha mu ndege zvikamu munda. Maitiro echinyakare ekugadzirisa zvinhu haasisina kukodzera kugadzirwa kunodiwa kwezvivakwa zvemazuva ano zvendiza. Naizvozvo, iko kushandiswa kwe titanium alloy zvikamu zvinogona kusangana nezvinodiwa zvekuvandudza ndege kusvika pamwero mukuru. Titanium chiwanikwa zvikamu zvakashandiswa zvakanyanya mukuvakwa kwendege. Semuenzaniso, screws uye nzungu zvinogona kushandiswa kugadzirisa hombe fuselage mafuremu, uye akakosha zvikamu senge injini mashizha uye kumhara giya inogona kugadzirwa neye titanium alloy zvinhu.

Kunyorera minda uye zvakanakira titanium chiwanikwa zvikamu

1.1 Titanium chiwanikwa zvikamu zvekushandisa munda

Tora B777 ndege yevanofamba semuenzaniso. Titanium alloy castings inoshandiswa mukugadzira iyo inokwira ndege. Zvinogona kuonekwa kuti mukugadzirwa kwendege dzevagari, tekinoroji yekushandisa ye titanium alloy zvikamu zvave zvakakura. Uye zvakare, titanium alloy zvikamu zvakare zvine kukosha kukuru mukuvandudza indasitiri yekuvhiya. Semuenzaniso, yeEuropean Doncasters kambani inoshandisa centrifugal yekukanda tekinoroji kuisa titanium alloy kuputsa torque.

1.2 yekushandisa zvakanakira titanium chiwanikwa zvikamu

Titanium chiwanikwa zvikamu zvine zvinotevera zvigadzirwa zvehunyanzvi:

- Kutanga, hapana chikonzero chekushandisa kuumba panguva yekuumba;

- Chechipiri, hapana chikonzero chekudyara yakawanda simba uye mari mudanho rekutanga gadziriro;

- Chechitatu, inogona kuvandudza zvinobudirira kushandiswa kwezvinhu. Titanium chiwanikwa zvikamu hazvisi kungovandudza chete kuchengetedzeka mashandiro enhandare nendege zvigadzirwa, asi zvakare kudzikamisa huwandu hwehukama hwakabatana, kunyatso chengetedza bhuku remusangano nguva, uye kuzadzisa mhedzisiro yenzira mbiri-nzira yemari uye mhando.

Zvimiro zve ndege titanium chiwanikwa zvikamu

2.1 isiri nyore kuora

Titanium chiwanikwa zvinhu zvine simba rakakwirira uye simba rekushisa, uye ine yakaderera density. Inofananidzwa nesimbi yezvinhu, inongova 60% yeiyo simbi yesimbi. Izvi zvinogadzira titanium alloy zvinhu pasina deformation matambudziko kunyangwe patembiricha dzakakwirira dze300 ° C kusvika 500 ° C. Iyo titanium alloy dhizaini yeimwe mhando yendege injini inogadziriswa neTC4 titanium alloy forgings. Kurema kwacho kuri 19.987kg, upamhi hwacho ndi600mm, uye kureba kuri 2800mm, asi ukobvu hwemadziro i1.50mm chete.

2.2 yakaderera tembiricha kuramba

Titanium alloy ine yakadzika yakadzika tembiricha kuramba, ndokuti, inogona kuramba iine yayo mega zvivakwa pasi peshure kana yakanyanya-yakaderera tembiricha mamiriro. Icho chinhu chine yakasimba yakaderera tembiricha kuramba. Zvinoenderana nehumwe bvunzo, zvinozivikanwa kuti titanium alloy iri -196 ° C. Pazasi, iyo tensile simba isb iri 1207Pa.

2.3 yakasimba ngura kuramba

Titanium chiwanikwa zvikamu zvinogona kushandiswa zvakanyanya mundiza yendege, chikonzero chakakosha ndechekuti ine yakanyanya ngura kuramba. Kana ndege iri kubhururuka pakakwirira, izvo zvinhu zviri mumhepo zvinozoita kuti zvikuvadze pamusoro pendege. Titanium chiwanikwa zvikamu zvinogona kunyatso kubata neichi chinokanganisa uye nekuona kuchengetedzeka kwendege.

2.4 Nemakemikari zvivakwa

Titanium alloys inogona kuita nemhando dzakasiyana dzesimbi zvinhu. Nerubatsiro rwekushanduka kwemakemikari, echimakanika zvivakwa zve titanium alloys zvinogona kuwedzerwa Semuenzaniso, mune yakanyanya tembiricha nharaunda iri pamusoro pe600 ° C, titanium alloys inogona kuita neoksijeni kuti iite inoenderana oxide dura.

2.5 yakadzika kudziya conduction

Iko kuiswa kwe titanium chiwanikwa zvikamu mundege kunogona kunyatso kudzikisira mukana wekutadza kwezvikamu zvendege, uye kudzivirira kudzivirira kwakanyanya kupisa kuitisa kwezvikamu zvendege zvinokanganisa mashandisirwo ezviwanikwa zvezvimwe zvikamu.

2.6 Diki modulus yekusimba

Mukuita kwekushandisa titanium alloy zvikamu, usazvigadzirise muzvikamu zvakapfava. Izvi zvinodaro nekuti iyo elastic modulus ye titanium alloy iri diki uye zviri nyore kuumbika. Uye zvakare, mu titanium machining maitiro, nekuda kweiyo huru rebound ye titanium alloy, zviri nyore kupfeka chishandiso.

Machining uye Matanho Ekushandisa eA ndege Titanium Alloy Zvikamu

China indasitiri yendege inokoshesa zvikuru kushandiswa kwezvinhu zvakasvibirira, uye iyo R&D inotarisa iri munzira yekuvandudza nekushandisa kuitira kusimudzira mashandiro enhandare.

3.1 Wedzera nzvimbo yekushandisa kwe titanium alloy castings

Kuenzaniswa nezvimwe titanium zvikamu, iyo yekudyara kukanda nzira ine yayo yakasarudzika zvakanakira:

- Ukuru hwekukanda hwakarurama, iyo yepamusoro isinganetsi, uye hukasha hwakaderera;

- Iyo inogona kukanda yakaoma yakaumbwa castings;

- Ipo ichivandudza mwero wekushandisa kwesimbi mbishi zvinhu, inogona zvakare kugadzirisa kugadzirwa kuchinjika uye kuchinjika.

Nekudaro, mune chaiyo yekuita maitiro, simba re titanium alloys haigone kuzadzisa zvizere izvo zvinodiwa pakuvaka ndege. Naizvozvo, iko kusimbisa kunofanirwa kuiswa mukuvandudzwa kwesimba rekusimba kwe titanium alloys panguva yekutsvaga nekusimudzira. Iyo yekumhanyisa kumhanyisa kwe titanium alloy chaiyo yekukanda tekinoroji munyika yangu yanga ichienderera ichiwedzera mumakore apfuura. Pamusoro peichi hwaro, iyo diagonal inodarika batira yave ichishandiswa zvakanyanya mundima yendege. Nekuda kwezvakanyanya kudiwa nendege yezvikamu zve titanium alloy, huwandu hwenhengo dzenyika yangu titanium alloy zvikamu zvakadzikira. Naizvozvo, sainzi uye tekinoroji inofanirwa kushandiswa kusimudzira danho rekukanda, kudzikisa zvigadzirwa zvemitengo uye zvigadzirwa zvekugadzira, uye kuzadzisa zvinangwa zvekugadzira zvakawanda .

3.2 Deredza mutengo wekuvandudza

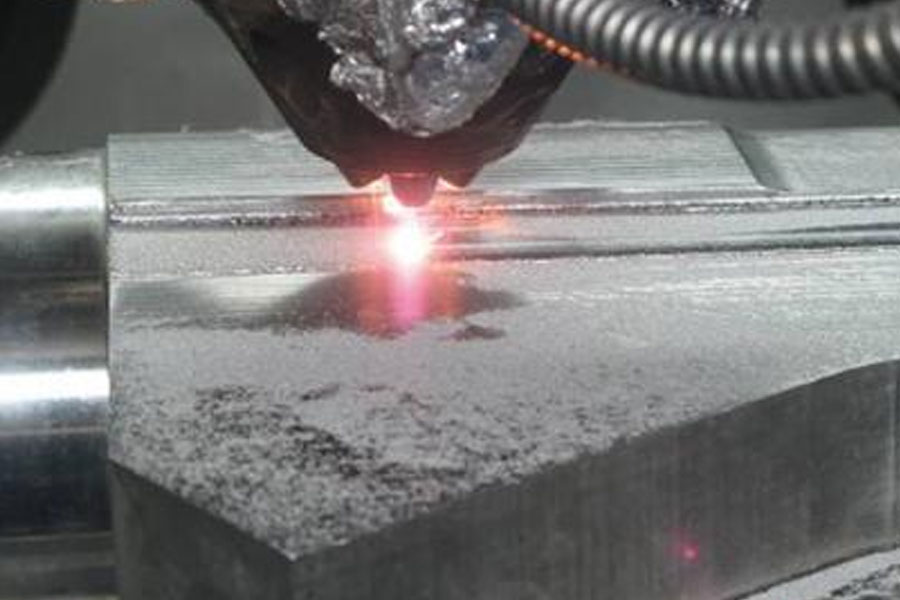

Pane hwaro hwe-yepamusoro-simba laser cladding uye nekukurumidza prototyping, titanium chiwanikwa poda laser yekuumba tekinoroji yave ichishandiswa zvakanyanya. Iyi tekinoroji inoshandisa yakakwira-simba laser danda kuti inyungudise iyo titanium chiwanikwa poda uye kuisimbisa pane substrate muchimiro chemadonhwe madiki, uye wozovimba nekombuta yekudzora tekinoroji kuti iyo laser musoro ifambe ichidzokororazve, nokudaro kuisira rukoko netaundi, uye pakupedzisira tora inodikanwa titanium chiwanikwa zvikamu modhi.

Parizvino, kuita kwese kweti titanium alloy mamiriro kwave nani zvakanyanya, uye huremu hwechikamu pachahwo hwadzikiswa zvakanyanya, hwakafarirwa neiyo nhandare yendege. Mukubatana nemamiriro chaiwo, mutengo weNb, Mo uye maV element mune titanium alloys inodhura, zvichitungamira kune yakakwira mbishi yezvinhu mutengo.

Naizvozvo, avhiyesheni titanium alloys ine yakaderera mutengo kudhara inokwezva kutarisisa kukuru Parizvino, vaongorori vakaona kuti Fe zvinhu zvinogona kushandiswa kutsiva zvinodhura zveNb, Mo uye V zvinhu, izvo zvisingakwanise chete kuona mashandiro ezvigadzirwa, asi zvakare zvinobudirira kudzikisira Iyo yekuisa mutengo we titanium alloy mbishi zvinhu.

3.3 Kugovera uye nzira yekudzivirira pamusoro

Mukuongorora kwepamusoro peBT3-1 uye OT4-1, zvinogona kugumiswa kuti kugoverwa kwehydrogen munzvimbo yepamusoro kwakaomarara, uye iyo hydrogen yezvinhu ichawedzera zvishoma nezvishoma, uye painosvika pakukosha kwazvo, iyo zvichaderera maererano. Parizvino, laser-mativi ekuumba tekinoroji uye titanium chiwanikwa zvikamu zvakanyatsobatanidzwa, uye yakakura-yakakura titanium chiwanikwa chikuru kutakura zvikamu zve ndege zvakagadzirwa.

3.4 Vandudza simbi Utilisation chinhu kuti inopisa nokuchengetedza anofa

Nzira inonyanya kushanda yekuwedzera simbi yekushandisa chinhu kushandisa yakaderera-oxidation uye isiri-oxidation kudziyisa. Kune titanium alloys, kupisa iyo isina chinhu nemhepo yakaoma kunogona kugadzirisa dambudziko iri. Zvinoenderana nehumwe tsvagiridzo, kana ichipisa muchoto chemagetsi, iyo tembiricha inofanirwa kudzorwa pa950 ℃ ~ 980 ℃. Uye zvakare, nekuitisa bvunzo paBT20 uye OT4-1 (TC1), kudziisa ese masampuli uye kufa kufoira zvakafanana, zvinogona kuwanikwa kuti yakaderera-tembiricha pre-oxidized mvere pamusoro peiyo isina chinhu inoratidza mhedzisiro, iyo inotungamira kune mhedziso yekuti iyo oxide yakaturikidzana uye iyo gasi inozadza nyika ine yakakosha pesvedzero pane zvemagetsi zvivakwa.

mhedziso

Muchirevo chekuenderera mberi kwesainzi uye tekinoroji, mabhizinesi mazhinji apedza shanduko, uye indasitiri yenyika yangu yealuminium yakawanawo mibairo yakanaka. Mukuita kwekukurumidza kusimudzira hupfumi, iyo titanium alloy indasitiri inoenderera ichikudziridza munzira yesimba rinowedzerwazve, ichigonesa titanium alloy zvikamu kuti zvishandiswe nemazvo mune mimwe minda, ichiisa hwaro hwakasimba hwekuvandudza kwesimba rekuchengetedza pamwe nekuderedza mweya.

Batanidza kuchinyorwa ichi: Inoshanda Machining YeTitanium Alloy Ndege Zvikamu

Dzokorora Chirevo: Kana pasina mirairo yakakosha, zvinyorwa zvese zviri pasaiti ino ndezvepakutanga. Ndokumbira uratidze kwakabva kudhindazve: https://www.cncmachiningptj.com/, thanks!

PTJ® inopa huwandu hwakazara hweCustom Precision cnc machine china services .ISO 9001: 2015 & AS-9100 yakasimbiswa. 3, 4 uye 5-axis inokurumidza chaiyo CNC yekumisikidza masevhisi anosanganisira ekugaya, kutendeukira kune vatengi maratidziro, Anokwanisa esimbi & epurasitiki michina zvikamu ne +/- 0.005 mm shiviriro.Secondary services inosanganisira CNC uye yakajairika kukuya, kuchera,kufa kukanda,jira simbi uye kutsikaKupa prototypes, yakazara kugadzirwa inomhanya, technical technical uye yakazara kuongorora motokari, aerospace, chakuvhuvhu & yechigadziko, akatungamira mwenje,zvokurapa, bhasikoro, uye mutengi electronics maindasitiri. Pa-nguva yekuendesa.Tiudze zvishoma nezve bhajeti rako reprojekiti uye inotarisirwa nguva yekuendesa. Ticharonga pamwe newe kuti upe masevhisi anodhura kwazvo kuti ubatsire iwe kuzadzisa chinangwa chako, Gamuchirai kuti Mutaure nesu ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

PTJ® inopa huwandu hwakazara hweCustom Precision cnc machine china services .ISO 9001: 2015 & AS-9100 yakasimbiswa. 3, 4 uye 5-axis inokurumidza chaiyo CNC yekumisikidza masevhisi anosanganisira ekugaya, kutendeukira kune vatengi maratidziro, Anokwanisa esimbi & epurasitiki michina zvikamu ne +/- 0.005 mm shiviriro.Secondary services inosanganisira CNC uye yakajairika kukuya, kuchera,kufa kukanda,jira simbi uye kutsikaKupa prototypes, yakazara kugadzirwa inomhanya, technical technical uye yakazara kuongorora motokari, aerospace, chakuvhuvhu & yechigadziko, akatungamira mwenje,zvokurapa, bhasikoro, uye mutengi electronics maindasitiri. Pa-nguva yekuendesa.Tiudze zvishoma nezve bhajeti rako reprojekiti uye inotarisirwa nguva yekuendesa. Ticharonga pamwe newe kuti upe masevhisi anodhura kwazvo kuti ubatsire iwe kuzadzisa chinangwa chako, Gamuchirai kuti Mutaure nesu ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

- 5 Sekaiichi machine

- Cnc Kugaya

- Cnc Kutendeuka

- Machining Maindasitiri

- Machining Maitiro

- Surface Kurapa

- Simbi yekushandisa

- Mapepa epurasitiki

- Upfu hweMetallurgy Mould

- Die Casting

- Zvikamu Garari

- Auto Metal Zvikamu

- Machinery Parts

- Akatungamira Heatsink

- Kuvaka Zvikamu

- Sravana Sameeralu Serial XNUMXth Mobile Parts

- Zvikamu Zvekurapa

- Zvikamu Zvemagetsi

- Zvichienderana machine

- Bicycle Parts

- Aluminum machine

- Titanium Kubata

- Stainless Simbi machine

- Mhangura machine

- Brass machine

- Super chiwanikwa machine

- Peek Kugadzira

- UHMW machine

- Sanganisa Machining

- PA6 Kugadzira

- PPS machine

- Teflon Kugadzira

- Inconel machine

- Danho Simbi machine

- Zvimwe Zvinyorwa