Hunhu Hwekuongorora HweMuchina Wepamusoro Micro-Maprofiles

Iwo Hunhu Ongororo yeMachining Surface Micro-profiles

|

Kutora iyo machining standard sampu sechinhu, mutsauko mukushata kwepamusoro kwenzvimbo dzakasiyana dzemuchina unodzidzwa, hunhu hwenzvimbo yepamusoro inowanikwa nekugadzira kwakasiyana hunoongororwa, uye iyo pamusoro penzvimbo ine roughness yakasiyana inowanikwa nenzira imwechete yekugadzira inocherechedzwa. . . Mhedzisiro yacho inoratidza kuti: iyo yepamusoro morphology uye roughness kukosha kweiyo standard samples inowanikwa neakasiyana machining nzira dzakasiyana kune akasiyana madhigirii; iyo density yechimiro chakanaka uye peak profile urefu hweakasiyana machining pamusoro morphologies akasiyana, izvo zvakasiyana kubva izvozvo. Iyo yekugadzirisa michina inoenderana; chimiro chepamusoro morphology yehukasha hwakasiyana hunowanikwa nemhando imwechete yekugadzira ine kuzvifananidzira, uye ine yakajairwa morphology uye maumbirwo maitiro, ayo anogona kushandiswa kusiyanisa akasiyana machining nzira. |

Nekukurumidza kusimudzira kwesainzi uye tekinoroji, zvinodiwa zvemhando yezvigadzirwa zvakasiyana-siyana zvemuchina zviri kuwedzera nekukwira. Iyo yepamusoro morphology uye chimiro hachingokanganisa ma mechanic properties ye mechanical system senge kukweshana uye kupfeka, kuomarara kwekubata, kuneta simba, mating zvivakwa, kutapurirana chaiko, kuita chisimbiso, uye kurongeka kwekuona, asi zvakare zvinokanganisa zvakananga kuita, hupenyu uye chitarisiko. yemuchina.

Mumichina midiki, iyo yepamusoro micro-morphology zvakare yakanyatso hukama nekukweshera kwayo, kupfeka, mafuta ekuzora uye zvimwe zvimiro zvekukwenya.

Iyo yepamusoro morphology (geometry uye manyorerwo, nezvimwewo) yemuchina wakagadzirwa zvinoenderana nehukama hwepakati pakati pechishandiso uye workpiece panguva yekucheka kufamba. Izvo hazvisi chete zvine chekuita neiyo chaiyo yekucheka nzira uye mamiriro ekucheka, asiwo kune dynamics yemuchina wekushandisa chimiro Mamiriro, maturusi ekucheka uye zvinhu uye ma mechanical maitiro e workpiece ane hukama [4]. Kudzidza kwehunhu uye mitemo yemukati meiyo micro-morphology yeakasiyana machining nzvimbo ndeyekukosha kwekutarisa kukosha kwekunzwisisa kwakadzama kwemaitiro ekugadzira nzira dzakasiyana dzemachining uye misiyano yavo, uye inopawo hwaro hwehunyanzvi hwekugadzira machining.

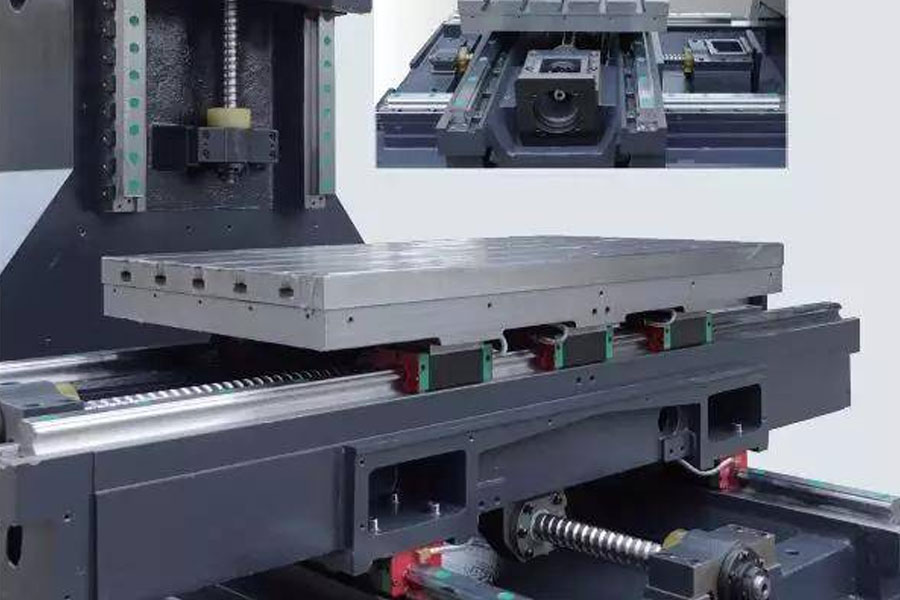

Munyori wepepa rino anotora machining (kutendeuka, kuronga, kupera, kugaya, kufinha, kukuya) akajairwa mabhuroki emuenzaniso sechinhu, anoongorora mutsauko wekushata kwepamusoro kunowanikwa nenzira dzakasiyana dzemachining, uye anoongorora nzira dzakasiyana dzekugadzira. chimiro chepamusoro uye chimiro chakawanikwa, uye mutemo we morphology wepamusoro nehutsinye hwakasiyana hunowanikwa nenzira imwechete yekugadzira yakaonekwa. Saka, kunzwisisa maitiro akasiyana machining nzira uye kusiyana kwavo.

1 Misiyano mukukasharara kwepasi kwenzvimbo dzakasiyana dzemuchina

Surface topography chiridzwa chinogona kuyera makumi maviri nesere emhando dzepamusoro pedenga paramita. Sarudza kureba kwesampling kuve 28mm uye nguva yesampling ive 5 μm kuyera iyo yepamusoro topography paramita yeakagadzirwa akajairwa sampuli block. Iyo inowanzo shandiswa pamusoro pepamusoro pehuremu hwepakati kukosha Ra inosarudzwa seyakaoma yekuongorora paramende kuti uongorore mutsauko mukukasharara kwepasi penzvimbo dzakasiyana dzemuchina. Nzira dzemuchina dzakasiyana dzinowana kukosha kweRa yemhando dzakasiyana-siyana dzakakasharara (tora avhareji yezviyero zvitatu), uye mutsauko pakati pekuyera kwakayerwa kukosha uye kushata kwechivharo chemuenzaniso.

- (1) Pane zvikanganiso zvakasiyana muhukasha hwakayerwa hwepamusoro peiyo topography yehukasha hwakafanana sampuli inowanikwa nenzira dzakasiyana dzemachining. Semuenzaniso, kune dzakasiyana nzira dzekugadzirisa, iyo yakayerwa roughness kukosha uye misiyano yepasi peiyo yakajairwa sampuli block ine roughness yeRa 0.8 μm zvakasiyana. Diki kusvika kuhombe), iyo yakayerwa hukasha kukosha idiki pane yemuenzaniso block roughness kukosha muhurongwa hwekufinha, kupera kwekugaya, uye kugaya kwakadzika (kubva padiki kusvika kuhombe).

- (2) Iko kukanganisa pakati peyero yakayerwa roughness kukosha kwepasi nekukasharara kwakasiyana kunowanikwa neiyo machining nzira uye roughness kukosha kweyakajairwa sampuli zvakare yakasiyana. Semuenzaniso, pakushandura kugadzirisa, kushata kwepamusoro kwezviyero zvakawanikwa ndeye Ra 0.8 μm, 1.6 μm, 3.2 μm, 6.3 μm, uye shanduko yekuchinja kwekukanganisa pakati pekuyera kwavo kwakayerwa kwakasiyana, uye kukosha kwehukusha ndiRa0. Iyo yakayerwa roughness values ye8μm, 1.6μm uye 6.3μm yakakura kupfuura kushata kweiyo standard sample block; apo kukosha kwekushata kuri Ra3.2 μm, iyo yakayerwa kushata ukoshi idiki pane roughness kukosha kweyakajairwa sampuli block. Zvisineyi, zvikanganiso zvakapimwa zvezviyero zvina zvakakasharara zvakagadziridzwa nekupera kwekugaya zvose hazvina kunaka, kureva kuti, zviyero zvakapimwa zvehukusha zvose zvishoma pane hukasha hwezviyereso zvakajairika.

Iyo micro-morphology hunhu hweakasiyana mashini enzvimbo anowanikwa nekushandisa akasiyana machining nzira (kutendeuka, kufinha, kupera kwekugaya, planing, flat milling, flat grinding) yemasampuli akajairwa ane roughness yakafanana (Ra0.8 μm) Pane musiyano mukuru. mu pamusoro morphology

-

(1) The density of the microstructure of akasiyana machined surface morphologies akasiyana, kubva pasi kusvika kumusoro, iwo ari flat milling, planing, end milling, flat grinding, boring, and turning.

-

(2) Iyo yepamusoro morphology uye chimiro cheakasiyana madhini enzvimbo ane zvimwe zvakafanana. Semuenzaniso, kutendeuka uye kufinha zvivakwa-zvakaita sechitubu; planing uye flat milling zvimiro zvakaita semafungu; kuguma kwekugaya uye kugaya kwakatsetseka ndeye serrated zvimiro.

- (3) Iyo peak shanduko amplitude yeiyo yepamusoro profiles ndeyekukuya, kutendeuka, kuronga, kupera kwekugaya, kufinha, uye kugaya kwakadzika mukudzika kurongeka, izvo zvine chekuita nekugadzirisa nzira dzeakasiyana machining nzira.

Iko kukosha kwehukukutu hwekuita kwekugaya kwakakwira zvakanyanya, uye zvinonyanya kupesvedzera zvinhu ndezvi:

-

① Iyo yekucheka (abrasive tsanga) yevhiri rekukuya haisi mutsara unoenderera wakatwasuka, unozosiya imwe nzvimbo yakasara pane workpiece mushure mekugaya.

-

②Mukukuya, kushanduka kwepurasitiki kwesimbi pamusoro pebasa rekushanda kunoita kuti kupisa kwekucheka kuwedzere nguva dzose, izvo zvinokurumidzira kupera kwegumbo rekukuya uye zvinokonzera extrusion yakakomba;

- ③Kusarudzwa kwemaparamendi akadai sehuwandu hwekukuya, mvura yekukuya uye mvumo yekukuya ine imwe pesvedzero pakushata kwepamusoro kwechishandiso.

3 Surface topography maitiro eimwe nzira yekugadzirisa ine hutsinye hwakasiyana

Iyo yepamusoro profile curve yeyakajairwa sampuli block ine hutsinye hwakasiyana (Ra0.8μm, 1.6μm, 3.2μm) inowanikwa nemuchina wekugaya. Kureba kwesampling i3.75mm, nguva yesampling i1.25μm, uye huwandu hwemasampling points i3,000 points. .

-

(1) Chimiro chepamusoro chine roughness yeRa 0.8 μm, 1.6 μm, 3.2 μm yakawanikwa nemuchina wekugaya wakafuratira une chimiro chakafanana chewavy, chinoratidza kuti chimiro chepamusoro chepamusoro chine roughness yakasiyana inowanikwa nenzira imwechete yekugadzira ine Kufanana, uye ine yakajairwa morphological uye chimiro maitiro, ayo anogona zvakare kushandiswa kusiyanisa akasiyana machining nzira.

-

(2) Kukosha kwepamusoro kweiyo flat milling surface profile kunowedzera nekuwedzera kwekukasharara ukoshi, iyo inopindirana neRa value parameter yeavhareji yehurefu hwehuwandu hwepamusoro.

- (3) The density of the surface micro-topography structure inodzikira nekuwedzera kwekukasharara, uye chinhambwe pakati pezvikomo chinowedzera.

4 Mhedziso

-

(1) Pane zvikanganiso zveakasiyana madhigirii pamusoro petopography roughness values ezvakafanana roughness standard samples dzakawanikwa nemachining akasiyana.

-

(2) Paunenge uchishandisa nzira imwechete yekugadzira kuti uwane nzvimbo dzine roughnesses dzakasiyana, kukanganisa pakati peyero yakayerwa kukosha uye kukosha kwekukasha kwemuenzaniso wemuenzaniso kwakasiyanawo.

-

(3) Yakasiyana machined pamusoro morphology, yakanaka dhizaini density uye peak mbiri kureba ese akasiyana, ayo ane hukama nemagadzirirwo ekugadzirisa.

-

(4) Iyo yepamusoro morphology uye chimiro chinowanikwa nenzira dzakasiyana dzemuchina zvine imwe nhanho yekufanana. Semuenzaniso, kutendeuka uye kufinha zvivakwa-zvakaita sechitubu; planing uye flat milling zvimiro zvakaita semafungu; kuguma kwekugaya uye kugaya kwakatsetseka ndeye serrated zvimiro.

- (5) Iyo yepamusoro morphology uye chimiro chehukasha hwakasiyana hunowanikwa nenzira imwechete yekugadzira zvakafanana, uye zvine chimiro chechimiro uye chimiro chechimiro, chinogona kushandiswa kusiyanisa nzira dzakasiyana dzekugadzira.

Batanidza kuchinyorwa ichi: Hunhu Hwekuongorora HweMuchina Wepamusoro Micro-Maprofiles

Dzokorora Chirevo: Kana pasina mirairo yakakosha, zvinyorwa zvese zviri pasaiti ino ndezvepakutanga. Ndokumbira uratidze kwakabva kudhindazve: https://www.cncmachiningptj.com/, thanks!

PTJ CNC shopu inogadzira zvikamu zvine yakanakisa michina zvivakwa, kurongeka uye kudzokorora kubva kusimbi nepurasitiki. 5 akabatana CNC azvikuya iripo.Kugadzira yakakwira-tembiricha chiwanikwa range inclouding inconel machine,monel machine,Kugadziriswa kweGeek Ascology,Carp 49 machine,Hastelloy machine,Nitronic-60 machine,Hymu 80 kugadzira,Danho Simbi machine, nezvimwe.,. Yakanakira kunyorera nzvimbo.CNC machining inogadzira zvikamu zvine yakanakisa mehendi zvivakwa, kurongeka uye kudzokorora kubva pasimbi nepurasitiki. 3-axis & 5-axis CNC yekugaya iripo.Ticharonga pamwe newe kuti tipe yakanyanya-isingadhuri masevhisi ekukubatsira iwe kuti usvike kune chako chinangwa, Gamuchirai Kwatiri isu ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

PTJ CNC shopu inogadzira zvikamu zvine yakanakisa michina zvivakwa, kurongeka uye kudzokorora kubva kusimbi nepurasitiki. 5 akabatana CNC azvikuya iripo.Kugadzira yakakwira-tembiricha chiwanikwa range inclouding inconel machine,monel machine,Kugadziriswa kweGeek Ascology,Carp 49 machine,Hastelloy machine,Nitronic-60 machine,Hymu 80 kugadzira,Danho Simbi machine, nezvimwe.,. Yakanakira kunyorera nzvimbo.CNC machining inogadzira zvikamu zvine yakanakisa mehendi zvivakwa, kurongeka uye kudzokorora kubva pasimbi nepurasitiki. 3-axis & 5-axis CNC yekugaya iripo.Ticharonga pamwe newe kuti tipe yakanyanya-isingadhuri masevhisi ekukubatsira iwe kuti usvike kune chako chinangwa, Gamuchirai Kwatiri isu ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

- 5 Sekaiichi machine

- Cnc Kugaya

- Cnc Kutendeuka

- Machining Maindasitiri

- Machining Maitiro

- Surface Kurapa

- Simbi yekushandisa

- Mapepa epurasitiki

- Upfu hweMetallurgy Mould

- Die Casting

- Zvikamu Garari

- Auto Metal Zvikamu

- Machinery Parts

- Akatungamira Heatsink

- Kuvaka Zvikamu

- Sravana Sameeralu Serial XNUMXth Mobile Parts

- Zvikamu Zvekurapa

- Zvikamu Zvemagetsi

- Zvichienderana machine

- Bicycle Parts

- Aluminum machine

- Titanium Kubata

- Stainless Simbi machine

- Mhangura machine

- Brass machine

- Super chiwanikwa machine

- Peek Kugadzira

- UHMW machine

- Sanganisa Machining

- PA6 Kugadzira

- PPS machine

- Teflon Kugadzira

- Inconel machine

- Danho Simbi machine

- Zvimwe Zvinyorwa