Kukosha kweCnc Machining Spacecraft Shell

Iyo Cnc Kugadzira kweSpacecraft Shell

|

Tsvagiridzo iri muchinyorwa ichi ine zvinotevera kukosha mukushandisa zvinoshanda:

|

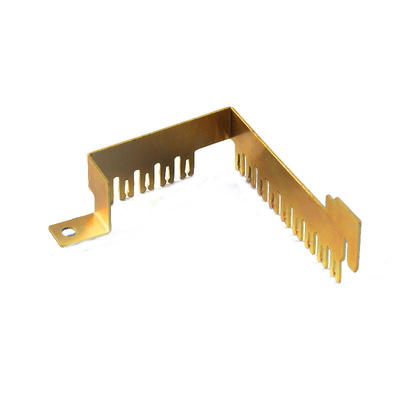

Spacecraft shell zvikamu chimwe chepakati pezvimiro zve spacecraft. Iwo anonyanya kuve makoni uye makoramu mateko ane dhayamita isingasviki 1300mm uye kureba isingasviki 1700mm. Zvinhu zvinoshandiswa zvinonyanya kuumbwa uye kukanda aluminium alloy, iyo inotakura basa rekubatanidza uye kutsigirwa. Zvinoenderana nehukama hwenzvimbo yechinhu chimwe nechimwe chinoshanda che spacecraft iri muchadenga, inogona kurongedza kufamba. Sezvo marudzi akasiyana ezvitundumuseremusere achiita mabasa akasiyana siyana, anotakura zvinhu zvakasiyana-siyana zvinoshanda, zvichiita kuti pave nemhando dzakasiyana-siyana dze spacecraft shell parts. Sezvinoratidzwa mumufananidzo 1-1, kune matatu akajairwa spacecraft magoko. .

Munguva ye "13th Five-Year Plan" nguva, nekuwedzera nekukurumidza kwemamishini emuchadenga, kudiwa kwezvikamu zvemabhomba zvechadenga kwakawedzera zvakanyanya.

wedzera. Zvichienzaniswa neyakajairwa michina zvigadzirwa, spacecraft shell zvikamu zvine maitiro emabhechi madiki, akawanda marudzi, nguva pfupi yekutenderera, uye nekukurumidza kutsiva chigadzirwa. Munguva yekugadzira, matambudziko akadai sekugovanisa basa risina kuenzana uye kushomeka kwenguva nenguva kwezvigadzirwa zvekugadzira zvinoramba zvichionekwa. Yechinyakare Iyo yakaderera-inoshanduka, yakakura-yakakura yekugadzira modhi yekambani haina kukwanisa kuzadzisa ikozvino kusimudzira zvinodiwa zvemhando dzakawanda uye yakakwirira-density panguva imwe chete.

Mazuvano, nekukurumidza kusimudzira kweindasitiri yekugadzira aerospace, musangano wekugadzira we spacecraft shell parts wasvika pane imwe nhanho yedhijitari. Nekushandiswa kweCNC machining nzvimbo, otomatiki inotungamirwa maAGV uye zvimwe zvivakwa zvehardware, CNC yekuchengetedza masisitimu, uye madhijitari ekugadzira masisitimu, Workshop yekutora data system uye imwe manejimendi yekuongorora software yakavakirwa pa "digital shell production line" chimiro chiri kuramba chichiwedzera. zvakakwana, kushanda kwekugadzira kwezvikamu zvishoma nezvishoma kwakavandudzwa, uye mhando yekugadzira yakave yakavimbiswa zviri nani. Nekudaro, iyo machining process dhizaini dhizaini ye spacecraft shell parts ichiri kutora nzira yechinyakare, ichivimba chete neyakagadzirwa dhizaini nemhizha, iyo inodzikamisa kuvandudzwa kwedanho rekugadzira. Mushure mekuongorora, iyo yechinyakare machining process.

Iyo nzira yekugadzira inonyanya ine zvinotevera zvipingamupinyi zviviri:

- (1) High technical zvinodiwa. Machining process nzira kuronga inoda kutarisisa hunhu hwakasiyana hwechigadzirwa. Zvichienzaniswa nezvimwe zvigadzirwa zvemuchina, zvinodiwa zvekugadzira zve spacecraft shell zvikamu zvakanyanya kuomarara, zvinoda kuti matekinoroji ave neruzivo rwehunyanzvi ruzivo uye kujairana nezviwanikwa zvekugadzira zvewekishopu. Uye zvakare, hunhu hwepfupi kutenderera uye nekukurumidza kutsiva kunodawo vashandi vekuita kuti vakurumidze kugadzira nzira inoshanda.

- (2) Maitiro ekugadzira maitiro akaderera uye mutengo wakakwira. Paunenge uchigadzira nzira yekugadzira, vashandi vekuita vanofanirwa kuverenga nhamba yakakura yegwara rekugadzira, kudhirowa uye manyorerwo ezvinyorwa kuitira kuti vawane ruzivo rwekuita rwuri muzvikamu. Mabasa acho akaoma uye kune akawanda anodzokororwa mabasa. Kunyanya, chimiro chezvipande zvemuchadenga chakaoma uye huwandu hwezvimiro hwakakura, uye pane kudiwa kwekukurumidzira kwehunyanzvi hwakabatana kutsigira kudzoreredza nekukurumidza kweruzivo rwemaitiro.

Kuburikidza nekuongororwa kwematambudziko aripo mumaitiro echinyakare ekugadzira, zvinoonekwa kuti zvikonzero zvakakosha zvinotadzisa kunyatsoshanda uye kwemhando yepamusoro dhizaini yemachining process ye spacecraft shell zvikamu ndezvi:

- (1) Historical process data haina kunyatso shandiswa. Muchigadziro chechikamu chekugadzira nekugadzira, huwandu hukuru hwe data data huchagadzirwa, uye yakawanda yeiyi nhoroondo data data haina kunyatso kuchengetwa uye kushandiswa, iyo inonyanya kuratidzwa mu: hapana yakamisikidzwa kuchengetedza, izvo zvinoita kuti zviome. kune vashandi vekugadzirisa kuti vatore ruzivo rwakakodzera rwekutarisa panguva yekugadzira maitiro; Kushaikwa kwemaitiro akakodzera eruzivo rwemigodhi nzira kwakakonzera kusakwanisa kushandisa zvinobudirira nhoroondo yedata data kutungamira nekukurumidza kuita sarudzo yemachining nzira.

- (2) Chiyero chehungwaru muhurongwa hwekuronga nzira yakaderera. Iyo yazvino CAPP tekinoroji ichiri mudanho rekusimudzira nekuvandudza, uye nzira yemaitiro ichiri kunyanya kurongwa nevashandi vemaitiro zvichienderana neruzivo rwekuita. Spacecraft shell zvikamu zvine hunhu hwekubatanidzwa kwakanyanya kwezvinhu. Kunyange zvazvo mabasa uye zvimiro zvezvikamu zvakasiyana-siyana, zvikamu zvezvikamu zvine kufanana kukuru.

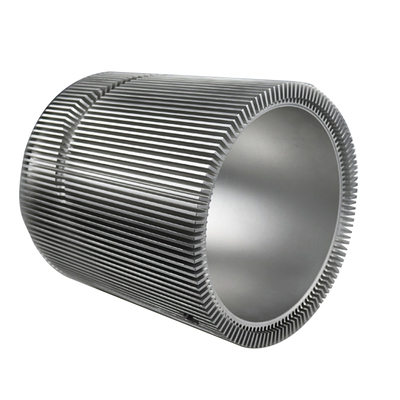

Iwo anonyanya kuumbwa neanopfuura gumi akajairwa makanda maumbirwo, maumbirwo emukati, mahwindo, uye grids. Machining maficha uye akati wandei asina kujairika atypical machining maficha. Panguva imwecheteyo, nekuda kwekufanana kwezvinodiwa zvekugadzira zvakadai sezvigadzirwa uye kunyatsojeka kwemaitiro anowanzoitwa ezvikamu, nzira dzekugadzira dzezvikamu zvezvikamu zvakasiyana-siyana zvinogona kushandiswa pakutsvaga.

Naizvozvo, ruzivo rwekugadzira machining runogona kubatanidzwa zvichienderana nemaitiro ekugadzira, uye nzira dzekugadzira munhoroondo data data inogona kucherwa uye kusundidzirwa kune vashandi vekuita, nekudaro ichivandudza kudzoreredza kwevashandi, uye kugonesa vashandi vekuita. nekukurumidza uye zvinobudirira kutungamira basa rekugadzira .

Uye zvakare, mukuita machining process dhizaini, mashandiro evashandi havafanire kungofunga nezve kugona kweiyo nzira nzira, asi zvakare kuderedza mutengo wekugadzira. Nekudaro, huwandu hwezvimiro zvespacecraft shell zvikamu zvakakura, uye iyo digital workshop ine huwandu hwakasiyana hwekugadzira michina uye simba rakasimba.

Tekinoroji inofanirwa kusarudza nzira dzakakodzera dzemuchina uye zviwanikwa zvekugadzira zvemachining maficha pasi pezvirambidzo zvemitemo yemaitiro, uye ozvibatanidza mumatanho ekuita. Matanho ekuita anorongedzerwa zvine hungwaru, kuitira kuti aarongedze mune ehupfumi uye inoshanda nzira nzira. Zviripachena, kana zvichienzaniswa neyakajairwa mekiniki zvikamu, basa rekuronga mafambiro echitundumuseremusere zvikamu zvinonyanya kuoma uye zvinoda hunyanzvi hwepamusoro hwevashandi vekuita.

Naizvozvo, zvinokwanisika kuvandudza kumhanya kweiyo nzira yekuronga nzira uye kuderedza kuverenga mutoro wevashandi vekuita kuburikidza nekutsvaga kweiyo nzira yekuronga tekinoroji yakavakirwa pane yakangwara algorithm.

Naizvozvo, kuti uenderane neiyo "yakawanda-mhando, diki-batch" maitiro ekugadzira e spacecraft shell zvikamu, vandudza maitiro.

Kushandiswa kwenhoroondo data uye hungwaru nhanho yekuronga nzira yekuronga. Ichi chinyorwa chichatora machining process dhizaini yeyakajairwa spacecraft shell zvikamu semashure ekutsvagisa, uye kuongorora iyo machining process ruzivo panguva yekugadzira maitiro uye hukama hwepakati pakati peruzivo.

Tungamira maitiro eiyo machining process ruzivo network. Pahwaro uhwu, rough set theory inounzwa kumugodhi inogona kuita sarudzo yemitemo muchiitiko chenhoroondo data, kuti ikurumidze kuwana machining nzira yehunhu hwemachining zvinoenderana nemitemo yesarudzo yekutarisa kwevashandi vemaitiro. Chekupedzisira, dzidza nzira yekuronga nzira pasi pekumanikidzwa kwemitemo yemaitiro kuti uvandudze hungwaru hungwaru hwekuronga nzira. Zvinoenderana nemaitiro einjiniya, nekuda kwenhamba shoma yeatypical zvikamu uye atypical maficha, iyo reusability haina kukwirira.

Kubva pane machining process dhizaini yezvakajairwa shell zvikamu zve spacecraft, pepa iri rinorongazve hukama hwemukati hwemachining process ruzivo uye inomisikidza nzira yeruzivo network modhi ine yakajeka sangano fomu, iyo inopa nyore kudzoreredza uye kushandisazve ruzivo rwemaitiro; tsvakurudzo nzira Nzira yemigodhi yemitemo yesarudzo inogona kushandisa zvizere ruzivo rwemagetsi kutungamira kuita sarudzo yekugadzira nzira; kunatsiridza hungwaru danho rekugadzira dhizaini nekudzidza nzira yekuronga nzira yakavakirwa pane chaiyo immune algorithm; uye shandisa nzira dziri pamusoro apa dzedzidziso uye tekinoroji yekutsvaga uye kudzidzira Gadzira chishandiso chekuburitsa maficha ekugadzira ezvakajairwa spacecraft zvikamu, chishandiso chemigodhi uye kuburitsa maitirwo esarudzo mitemo, uye nehungwaru kuronga chishandiso chenzira dzemagadzirirwo ekuvandudza maitiro ekugadzira uye huchenjeri nhanho. yezvakajairwa spacecraft shell parts.

Mapeji Inoenderana:Aicraft Zvikamu

Batanidza kuchinyorwa ichi: Kukosha kweCnc Machining Spacecraft Shell

Dzokorora Chirevo: Kana pasina mirairo yakakosha, zvinyorwa zvese zviri pasaiti ino ndezvepakutanga. Ndokumbira uratidze kwakabva kudhindazve: https://www.cncmachiningptj.com/, thanks!

PTJ CNC shopu inogadzira zvikamu zvine yakanakisa michina zvivakwa, kurongeka uye kudzokorora kubva kusimbi nepurasitiki. 5 akabatana CNC azvikuya iripo.Kugadzira yakakwira-tembiricha chiwanikwa range inclouding inconel machine,monel machine,Kugadziriswa kweGeek Ascology,Carp 49 machine,Hastelloy machine,Nitronic-60 machine,Hymu 80 kugadzira,Danho Simbi machine, nezvimwe.,. Yakanakira kunyorera nzvimbo.CNC machining inogadzira zvikamu zvine yakanakisa mehendi zvivakwa, kurongeka uye kudzokorora kubva pasimbi nepurasitiki. 3-axis & 5-axis CNC yekugaya iripo.Ticharonga pamwe newe kuti tipe yakanyanya-isingadhuri masevhisi ekukubatsira iwe kuti usvike kune chako chinangwa, Gamuchirai Kwatiri isu ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

PTJ CNC shopu inogadzira zvikamu zvine yakanakisa michina zvivakwa, kurongeka uye kudzokorora kubva kusimbi nepurasitiki. 5 akabatana CNC azvikuya iripo.Kugadzira yakakwira-tembiricha chiwanikwa range inclouding inconel machine,monel machine,Kugadziriswa kweGeek Ascology,Carp 49 machine,Hastelloy machine,Nitronic-60 machine,Hymu 80 kugadzira,Danho Simbi machine, nezvimwe.,. Yakanakira kunyorera nzvimbo.CNC machining inogadzira zvikamu zvine yakanakisa mehendi zvivakwa, kurongeka uye kudzokorora kubva pasimbi nepurasitiki. 3-axis & 5-axis CNC yekugaya iripo.Ticharonga pamwe newe kuti tipe yakanyanya-isingadhuri masevhisi ekukubatsira iwe kuti usvike kune chako chinangwa, Gamuchirai Kwatiri isu ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

- 5 Sekaiichi machine

- Cnc Kugaya

- Cnc Kutendeuka

- Machining Maindasitiri

- Machining Maitiro

- Surface Kurapa

- Simbi yekushandisa

- Mapepa epurasitiki

- Upfu hweMetallurgy Mould

- Die Casting

- Zvikamu Garari

- Auto Metal Zvikamu

- Machinery Parts

- Akatungamira Heatsink

- Kuvaka Zvikamu

- Sravana Sameeralu Serial XNUMXth Mobile Parts

- Zvikamu Zvekurapa

- Zvikamu Zvemagetsi

- Zvichienderana machine

- Bicycle Parts

- Aluminum machine

- Titanium Kubata

- Stainless Simbi machine

- Mhangura machine

- Brass machine

- Super chiwanikwa machine

- Peek Kugadzira

- UHMW machine

- Sanganisa Machining

- PA6 Kugadzira

- PPS machine

- Teflon Kugadzira

- Inconel machine

- Danho Simbi machine

- Zvimwe Zvinyorwa