Kuongororwa kweMatambudziko muKuchina Grey Cast Iron

Kuongororwa kweMatambudziko muKuchina Grey Cast Iron

|

Kuti tigadzirise machining matambudziko egrey iron kukanda mukambani, izvo zvinhu uye zvivakwa zvecryry pig uye castings zvakaongororwa nemaoikorosikopu, kuongorora elektroni maikorosikopu, Brinell kuomarara, micro Vickers kuomarara uye spectrum ongororo. Mhedzisiro yacho inoratidza kuti zvemukati zveS uye P zve26 # yenguruve iron yaive pamusoro penzvimbo yepamusoro, zvirimo zveSi makumi maviri neshanu # pig yesimbi yakaderera, saka makemikari akaumbwa haagutsikane maitiro. Iyo kabhoni yakaenzana yeiyo castings i22%, inova ndeye yakakwira kabhoni yakaenzana castings. Chiyero cheSi naC chiri 0.46, chiri padivi rakaderera. Izvo zvirimo zveSi naMn mukukanda zvakaderera, kuwedzera kune zvirimo zveCr zvakakwirira, izvo zvinokwana kuburitsa zvinotyisa chiitiko, pane V chinhu mune yakanyanya castings. iyo microstructure yekukanda ndeye ferrite, pearlite, graphite uye carbide. Chimwe chikamu che carbide chine Cr, V uye zvimwe zvinhu zvidiki-zvinokanganisa zvinhu, uye kuomarara kwemakemikari kuri pamusoro pe1 100 HV, chinova ndicho chikonzero chikuru chekugadzira michina zvinonetsa. Naizvozvo, kuitira kuti uvandudze machina c apacity, chekutanga, zvirimo V uye Cr hazvifanire kupfuura muyero. Chechipiri, zvirimo zveSi zvinofanirwa kuwedzerwa uye zvinofanirwa kutanga zvasarudza kuwedzera mune inoculation. Nekuda kwekukanda, iyo carbide inogona kuora nekuita graphing annealing. |

Makona machena ehutete-akavakirirwa grey simbi castings zvakajairika hurema mukukanda [1-4]. Kazhinji, madiki castings ane matete masvingo uye anokandwa mujecha regirini. Kunyangwe iwo makemikari ekuumbwa kwesimbi yakanyungudutswa akakodzera, nekuda kwekukanganiswa kweakakora madziro ukobvu uye kupisa kwekushisa kwekukanda, iwo makobvu uye matete mativi eakafanana kukanda. Zvese zviri mukati nekunze zvinogona kuwana rakasiyana sangano. Kunyanya makona emakanda anokombamira kumiromo chena, izvo zvinokonzeresa matambudziko mukugadzira, zvichikonzera izvo zvinonzi izvo "zvakaoma zvinhu". Zvizhinji zvezvikamu zvegrey cast iron "zvinhu zvakaoma" zvinoitika muchikamu chechikamu chakakasharara. Senge: mativi nemakona, maburi, nzvimbo dzakaumbana, nzvimbo, nezvimwewo kuomarara kwechinhu zvine chekuita nekombamiro yemuromo chena. Tichifunga nezvematambudziko akaoma ekugadzirisa mune kugadzirwa chaiko kweimwe kambani, bepa iri rinoita zvakarongeka kudzidza, rinoongorora zvikonzero zve "zvakaoma zvinhu", uye rinopa mhinduro dzinoenderana.

1 Zvinhu zvekuyedza uye nzira

Kukanda nguruve simbi 22 #, 26 # uye muchina uchikanda nhamba 0 # zvakatorwa pane saiti. Sampling netambo yekucheka yakaitwa zvakateerana, uye kucherechedzwa kwemaziso matema uye kuongorora matishu kwakaitwa. Kemikari pane cast iron uye castings

Kuumbwa bvunzo kusabvisa simba rezvinhu zvekutsvagisa pane kuita kwekugadzirisa kwekukanda. Kukanda kwacho kwakatorwa simbi yekucherechedza metallographic muZEISS Optical uye scanning microscopes, HBS-3000 digital Brinell hardness tester uye HTM-1000 TM micro hardness tester yakashandiswa pakuomesa kuyedza. Iko makemikari akaumbwa enguruve simbi uye castings inoratidzwa mu Tafura 1.

| C | Si | Mn | P | S | W | Te | Bi | Cr | V | Ce | B | Mo | |||

| 0 3.73 # | 1.75 | 0.17 | 0.15 | 0.12 | ≤0.01 | 5 | 5 | 0.11 | 0.027 | 0.01 | 0.004 | 4 | ≤0.01 | ||

| 22 4.08 # | 1.86 | 0.055 | 0.07 | 0.02 | ≤0.01 | 5 | 5 | ≤0.010 | ≤0.010 | 0.01 | 0.002 | 2 | ≤0.01 | ||

| 26 3.38 # | 2.51 | 0.17 | 0.45 | 0.095 | ≤0.01 | 5 | 5 | 0.023 | 0.044 | 0.01 | 0.008 | 9 | ≤0.01 |

2.1 Kuumbwa kwemakemikari

Kana iyo grey yakakanda simbi kabhoni iripo muchimiro che carbides, inowedzera maitiro ekuchenesa, izvo zvinoita kuti machining anetse uye inokonzeresa iyo inonzi "yakaoma zvinhu" dambudziko. Naizvozvo, grey yakakanda simbi inofanirwa kudzikisira tsika yekuchenesa, kuitira kuti kabhoni irambe iri muchimiro che graphite. Zvinhu zvakasiyana-siyana zvine mhedzisiro pane iyo graphitization maitiro, uye mamwe anokurumidza matomboInking, kumwe kunonoka graphitization. Kazhinji kutaura, zvizhinji zvezvinhu zvinogona kushomeka simba rekubatanidza pakati pesimbi neakabhoni maatomu uye nekuwedzera kuzvisarudzira kugona kwemaatomu esimbi kunogona kukurudzira graphitization yesimbi yakakanda; kana zvisina kudaro, zvinodzivisa graphitization yesimbi yakakoswa, ndiko kuti, kuwedzera maitiro emuromo chena. . Kuedza kukanda simbi

Hunhu hwesimbi yenguruve uye kubviswa kwesimba rezvinhu zvekuteedzera pakuchenesa kwema castings. Zvinhu zvishanu uye zvakajairika machena zvinhu zvezvinhu zvakasvibirira uye castings zvakaedzwa. Muenzaniso wega wega wakaedzwa zvinhu gumi nematatu. Yakazara makumi matatu nemasere mativi enguruve yesimbi uye castings akaedzwa. Iyo kemikari inogadzirwa inoratidzwa muTafura 13.

China yakaumbwa simbi yenguruve simbi standard (GB / T 718-2005) [5], mune yakajairwa, iyo Si yezvinhu makumi maviri neshanu yenguruve simbi iri 22% ~ 2.00%, uye iyo Si yezvinhu makumi maviri nenhatu # yenguruve simbi iri 2.40% ~ 26%. Sekureva kweTafura 2.40, yekambani yenguruve yesimbi 2.80 # uye 2 # bvunzo yakaratidza kuti iyo Si yezvinhu makumi maviri neshanu yenguruve iron yaive 22, iyo isina kusangana nemuganhu wezasi wechiyero.

Iyo inosangana neyakajairwa, uye iyo Mn yezvinhu zvakare yakaderera. 26 # yenguruve iron P uye S zvemukati zvakanyanyisa, P zvemukati zvinosvika padanho rechishanu, S zvemukati zvinopfuura chiyero, uye zvine imwe huwandu hweCr. Muedzo wekuumbwa kwekukanda 5 # unoratidza kuti C chete yezvinhu zvichenesa yasvika pakuchenesa, uye zvirimo zvezvimwe zvinhu zvisati zvasvika pane zvirimo zvekukonzeresa, saka kukanganisa kwacho hakuna basa. Zvichienzaniswa nekusarudzwa kwezvinhu zvishanu mu "Casting Handbook" [0], zvinogona kuoneka kuti kabhoni yezvakakandirwa muchidzidzo ichi yakakwira zvakanyanya, izvo zveSi zvakadzikira, uye Mn zvemukati zvakadzikira. .

2.2 Kuoma bvunzo

Mune iyo HBS-3000 dhijitari inoratidzira Brinell hardness tester, iyo bvunzo ndeye 1875 N, iyo indenter dhayamita iri 2.5 mm, uye kuomarara kwemiedzo mishanu kunoratidzwa muTafura 5. Pane yedhijitari microhardness tester, iyo chena nzvimbo mune ye optical foto. yakamakwa ne microhardness. Mhedzisiro yacho inoratidzwa muTafura 2. Naizvozvo, kunyangwe hazvo pavhareji kuomarara kwemacroscopic matrix kwakadzika kwazvo, chete kuomarara kweBlinell kuri kuita 3 HB, kuomarara kwenzvimbo yaro kwakanyanya, kusvika kune kuomarara kweVickers ingangoita 145 1 HV . Iyo diki gomba, iyo inowedzera kuoma. Zvinoenderana nezvinyorwa, kuoma kwephosphorus eutectic ndeye 000 ~ 500 HV, ledeburite ≤ 700 HV, uye carbide> 800 HV.

Naizvozvo, mhedzisiro yekuoma kwekuoma inoratidza kuti iyo chena nzvimbo yakaoma uye inopwanya cementite carbide, iyo inonyanya kusanganisa phosphorus eutectic, chinova chikonzero chikuru chezvinhu zvakaoma. Kuti unyatsoziva kuumbwa kweiyi carbide, simba remagetsi rinotariswa rinodiwa.

2.3 Kuongorora kwesimba kwesimba

Kuwedzera kwakasarudzika kwenzvimbo yewhite chena inoratidzwa muFiri. 2 uye Fig. 3. Inozivikanwa nekuparadzirwa kwemaburi akadzikiswa mumatrix uye hunhu hweeutectic. Naizvozvo, kuongororwa kwesimba kwenzvimbo ino kunoratidza kuti zvinhu zviri muchikamu chakadzikira chenzvimbo iyi Fe, P uye C chinhu, saka chinotongwa seFe3 (C, P), P chinhu chinochengetwa

Kusarura. Iyo P element mune yakadzokororwa chikamu yakakwira, kwete eutectic chigadzirwa, asi gomba rakaumbwa neyekupedzisira solidification uye shrinkage. Mufananidzo 4 Energy spectrum ongororo mhedzisiro inoratidza kuti kuwedzera kune Fe, P uye C zvinhu, iyo chena nzvimbo ine Cr uye V, inogadzira alloy carbides, ayo akaoma uye akaomarara.

Tora kucheka.

2.4 Ongororo yesangano

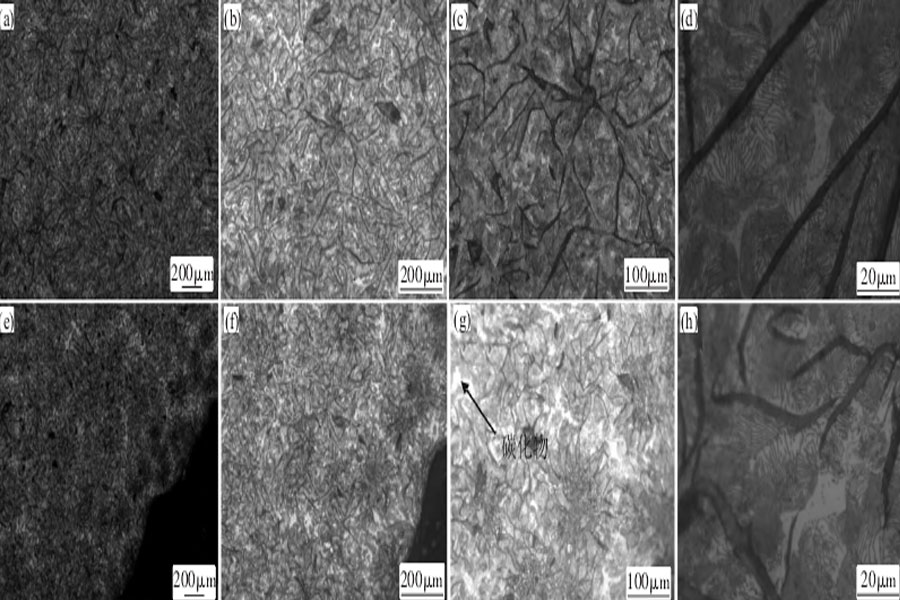

Mufananidzo wekuratidzira unoratidza iyo metallographic chimiro chekukanda kunoitwa nekucheka ne4% nitric acid doro, sezvakaratidzwa muMufananidzo 5. Pakati pavo, a, b, c, uye d ndiwo musimboti mamiriro ekukanda, uye e, f, g, uye h ndiwo mamiriro ekumakanda. a, b, c, d uye e, f, g, h inoenderana nemakumi mashanu, zana, mazana maviri, uye chiuru zvakapetwa mapikicha emifananidzo. Mufananidzo wakavhenekwa munyama unoratidzwa muMufananidzo 50, uye museve unonongedzera kunzvimbo chena mumufananidzo unoenderana wetishu, inova carbide. Iyo chena block nzvimbo ndeye carbides, mafrakes ari graphite, uye iyo grey nzvimbo iri pearlite. Izvo zvinogona kuoneka kuti iyo metallographic chimiro ndeye ferrite + pearlite + graphite + carbide, yakarongedzwa chimiro. Kuchena kwemakona zviri pachena kuti kwakakomba kupfuura kuya kwemoyo. Tichienzanisa neGG / T100-200, zvinogona kuonekwa kuti [1,000], nyama yemoyo ndiyo yekutanga

Iyo yakasvibira nyeredzi-yakaita graphite F mhando ine hurefu hweanosvika 150 μm uye upamhi hweanosvika 5 μm. Izvi zvinoumbwa neakakwira-kabhoni simbi yakanyungudutswa pasi pemamiriro akakurisa eescooling. Iyo yekumucheto dura dhizaini yakanaka yakamonana graphite yakaunganidzwa mune chrysanthemum-senge kugovera kworudzi B graphite. Iyo yakareba ingangoita zana μm uye upamhi i100 μm. Sarudza huwandu hwemacarbides

Huwandu hwe carbide iri munyama yemoyo ingangoita 5%, ichisvika padanho 3. Huwandu hwemacarbides ari kumucheto tishu ndeye 10%, inosvika padanho 4. Kana kabhoni iri muchimiro che graphite, iyo graphite inogona kushandiswa lubrication panguva machine, uye nokuveza zviri nyore. Kana kabhoni iripo muchimiro che carbide (Fe3C), nekuti Fe3C cementite yakaoma uye inopwanya, machining anonetsa, kunyanya kana iine zvimwe zvinokonzeresa zvinhu (zvakaita seCr), alloy cementite ((Fe, M) 3C) Ichi chinoumba chiri zvakaoma uye zvakanyanya kuoma kucheka, uye iyo inonzi "yakaoma zvinhu" dambudziko inoitika panguva yekugadzira [8]. Naizvozvo, mukukanda kwegrey iron zvikamu, zvinodikanwa kudzikisa huwandu hwekabhoni kuti udzivise kuoneka kwema carbides, uye kutora matanho ekukurudzira carbon graphitization kana zvichidikanwa.

Kuongorora nekukurukurirana

Huru zvinhu zvinokanganisa mashandiro mashandiro e castings ndiwo makemikari anoumbwa nesimbi yakakandwa uye iyo solidification kutonhora mwero. Iko kabhoni zvemukati uye nesilicon zvemukati mune zvemakemikari akaumbwa esimbi simbi ndiyo inonyanya kukosha kutonga zvinhu. Iyo inotonhorera mwero wekukanda kunyanya kunoenderana nemadziro pakukora kwekukanda. Kana zvirimo zve kabhoni nesilicon musimbi yakakandwa zvinogara zviripo, iyo yakaonda mutete wekukanda, iko kukura kweye simbi yekuchenesa. Kana ukobvu hwemadziro hwekukanda hwaramba huripo, hazvo huwandu hwese hwekabhoni nesilicon musimbi yakakandwa, hunyanzvi hwekuita graphitization yesimbi yakakandwa.

Iyo kabhoni yakaenzana nekukanda muchidzidzo ichi i4.36%, inova yakakwira-kabhoni yakaenzana kukanda; iyo Si / C ratio iri 0.46, iri pasi. Kuwedzera iyo kabhoni yakaenzana kunoita kuti graphite flakes ive mukobvu, nhamba inowedzera, uye simba nekuomarara kuderera. Kuwedzera Si / C kunogona kudzora tsika yemuromo chena.

Mukugadzirwa kwegrey cast iron, simba rekupisa uye mitezo yekubata inodawo kutariswa. Kuwedzera tembiricha yesimbi yakanyungudutswa mukati meimwe nhanho kunogona kuita kuti grafiti inatsiridzike, chimiro chematrikisi chinyatsonaka, simba rekusimbisa rakawedzera, uye kuomarara kwakaderera. Izvo zvinodikanwa kuti unyatsoongorora kurongedza kwechaji, simbi yekunyungudisa, uye simba rezvinhu zvemakemikari. Iyo inoculation kurapwa ndeyekuwedzera iyo inoculant kune yakaumbwa simbi kushandura iyo metallurgia mamiriro yesimbi yakanyungudutswa pamberi pesimbi yakanyungudutswa inopinda mune yekukanda mhango, uye kuwedzera isiri-isingaite nucleus iyo graphite yekunatsiridza. Nekudaro nekuvandudza iyo microstructure uye kuita kwesimbi yakakandwa. Kazhinji inoculants inosanganisira ferrosilicon, calcium silicon uye graphite. Kubatanidza zvigadzirwa zvedu nemitengo yekugadzira, zvinokurudzirwa kushandisa ferrosilicon (75% yesilicon, iyo yekuwedzera huwandu inenge 0.4% yehuremu hwesimbi yakanyungudutswa). Chechipiri, barium ferrosilicon uye strontium ferrosilicon. Ferrosilicon inoculates yekukurumidza-kuita mhedzisiro, inosvika pakakwirira mukati me1.5 min, uye ichiderera kune isiri-nhumbu nyika mushure me8 ~ 10 min, iyo inogona kudzikisira mwero we supercooling uye chena muromo muromo, kuwedzera huwandu hwemasumbu eutectic, fomu A-mhando graphite, kunatsiridza kufanana kwechikamu, uye kuwedzera kuramba. Tensile simba iri 10-20MPa. Zvakaipira: murombo kuramba kuora. Kana iyo yekupedzisira inoculation maitiro isiri kushandiswa, haina kukodzera kune yakakura madziro ukobvu misiyano uye yakareba kudira nguva.

Barium ferrosilicon ine simba rakasimba rekuwedzera huwandu hwemasumbu eutectic uye kugadzirisa chikamu chakaenzana kupfuura ferrosilicon. Iko kugona kurwisa kuderera kwakasimba, uye iyo inoculation mhedzisiro inogona kuchengetwa kwemaminetsi makumi maviri. Inokodzera mamakisi akasiyana siyana egrey cast cast iron zvikamu, kunyanya inokodzera yakakura-yakakura gobvu-rakakomberedzwa zvikamu uye mamiriro ekugadzira aine akareba anodurura nguva.

Strontium ferrosilicon ine 30% kusvika 50% yakakwira yekuchena kudzikisira kugona kupfuura ferrosilicon, uye ine nani chikamu chikamu uye kurwisa-kuora kugona pane ferrosilicon. Panguva imwecheteyo, haina kuwedzera huwandu hwemasumbu eutectic, iri nyore kunyungudika, uye ine slag shoma. Matete-akaomeswa mativi, kunyanya zvikamu zvinoda kudzikira uye kuvuza neakakwira eutectic masumbu haadiwe.

Iyo Mn yezvinyorwa zvevakakanda mune ino fundo yakaderera. Manganese pachayo chinhu chinotadzisa graphitization, asi manganese inogona kudzora iyo yakasimba kuchenesa mhedzisiro yesarufa. Naizvozvo, mukati memuganhu wekukanganisa zvinoitwa nesarufa, manganese inotora chikamu mukusimudzira graphitization. Kudzidzira kwakaratidza kuti kuwedzera kwemanganisi zvemukati hakugone kuwedzera uye kunatsiridza pearlite, asi hazvikuvadze kuzorodza zvakakodzera kutonga kwesarufa. Naizvozvo, zvinokurudzirwa kuti zvakafanira kuwedzera iyo Mn yezvinhu.

4 Mhedziso

Chikonzero chikuru chekushomeka kwemuchina we castings muchidzidzo ichi kuoneka kwecementite carbides, kunyanya iyo cementite carbides yemarloys ane Cr, V nezvimwe zvinhu ndizvo zvikonzero zvikuru zvekusanganisa michina. Kugadzirisa dambudziko iri, zano rekutanga kudzikisa kana kubvisa macarbides musangano. Kuchinja kuumbwa kweanokanda uye kugadzirisa maitiro ekugadzira inzira dzinoshanda. Yakasanganiswa neyakajeka mamiriro ekugadzirwa kwevakakanda muchidzidzo ichi, zvinotevera mazano ekugadzira anoiswa kumberi:

- (1) Kuti uwedzere zvemukati zvesilicon, sarudzo yekutanga kuwedzera inoculant usati wadira. Kune ferrosilicon (75% yesilicon), barium ferrosilicon uye strontium ferrosilicon inogona zvakare kushandiswa zvinoenderana nenguva yekudira uye pa-saiti mhedzisiro. Inokurudzirwa kushandisa kemikari inoculants (Si-Ba uye RE-Si).

- (2) Wedzera manganese zvemukati mukukanda kuti ubvise yakasimba chena mukanwa mhedzisiro yesarufa.

- (3) Kuvandudza kunaka kwesimbi yenguruve. 26 # Nguruve simbi P uye S zvemukati zvakanyanyisa.

- (4) Deredza Cr zvemukati mukukanda. Izvo zvemukati zveCr (> 0.1) mune izvo castings zvinogona kutogadzira mhedzisiro yekuchenesa. Kr inogona kuwedzera zvakanyanya kuomarara uye kukanganisa mashandiro emuchina.

Batanidza kuchinyorwa ichi: Kuongororwa kweMatambudziko muKuchina Grey Cast Iron

Dzokorora Chirevo: Kana pasina mirairo yakakosha, zvinyorwa zvese zviri pasaiti ino ndezvepakutanga. Ndokumbira uratidze kwakabva kudhindazve: https://www.cncmachiningptj.com/, thanks!

PTJ CNC shopu inogadzira zvikamu zvine yakanakisa michina zvivakwa, kurongeka uye kudzokorora kubva kusimbi nepurasitiki. 5 akabatana CNC azvikuya iripo.Kugadzira yakakwira-tembiricha chiwanikwa range inclouding inconel machine,monel machine,Kugadziriswa kweGeek Ascology,Carp 49 machine,Hastelloy machine,Nitronic-60 machine,Hymu 80 kugadzira,Danho Simbi machine, nezvimwe.,. Yakanakira kunyorera nzvimbo.CNC machining inogadzira zvikamu zvine yakanakisa mehendi zvivakwa, kurongeka uye kudzokorora kubva pasimbi nepurasitiki. 3-axis & 5-axis CNC yekugaya iripo.Ticharonga pamwe newe kuti tipe yakanyanya-isingadhuri masevhisi ekukubatsira iwe kuti usvike kune chako chinangwa, Gamuchirai Kwatiri isu ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

PTJ CNC shopu inogadzira zvikamu zvine yakanakisa michina zvivakwa, kurongeka uye kudzokorora kubva kusimbi nepurasitiki. 5 akabatana CNC azvikuya iripo.Kugadzira yakakwira-tembiricha chiwanikwa range inclouding inconel machine,monel machine,Kugadziriswa kweGeek Ascology,Carp 49 machine,Hastelloy machine,Nitronic-60 machine,Hymu 80 kugadzira,Danho Simbi machine, nezvimwe.,. Yakanakira kunyorera nzvimbo.CNC machining inogadzira zvikamu zvine yakanakisa mehendi zvivakwa, kurongeka uye kudzokorora kubva pasimbi nepurasitiki. 3-axis & 5-axis CNC yekugaya iripo.Ticharonga pamwe newe kuti tipe yakanyanya-isingadhuri masevhisi ekukubatsira iwe kuti usvike kune chako chinangwa, Gamuchirai Kwatiri isu ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

- 5 Sekaiichi machine

- Cnc Kugaya

- Cnc Kutendeuka

- Machining Maindasitiri

- Machining Maitiro

- Surface Kurapa

- Simbi yekushandisa

- Mapepa epurasitiki

- Upfu hweMetallurgy Mould

- Die Casting

- Zvikamu Garari

- Auto Metal Zvikamu

- Machinery Parts

- Akatungamira Heatsink

- Kuvaka Zvikamu

- Sravana Sameeralu Serial XNUMXth Mobile Parts

- Zvikamu Zvekurapa

- Zvikamu Zvemagetsi

- Zvichienderana machine

- Bicycle Parts

- Aluminum machine

- Titanium Kubata

- Stainless Simbi machine

- Mhangura machine

- Brass machine

- Super chiwanikwa machine

- Peek Kugadzira

- UHMW machine

- Sanganisa Machining

- PA6 Kugadzira

- PPS machine

- Teflon Kugadzira

- Inconel machine

- Danho Simbi machine

- Zvimwe Zvinyorwa