Iko Kushanda Kweindasitiri Robhoti Mashini Kuisa Uye Kuburutsa

Iko Kushanda Kweindasitiri Robhoti Mashini Kuisa Uye Kuburutsa

|

Ichi chinyorwa chekutanga chinosuma kuumbwa, kukosha kwekushandisa uye hunhu hwemaindasitiri emuchina machining kurodha uye kudzikunura mafomu, uye kuongororwa kwakadzama kwekuomarara uye kurongeka kwemarobhoti emabhizimusi mune emabhizimusi emuchina machining kurodha uye kudzikisa mafomu, pamwe nezvinetso zvekukurumidza kupora mushure mekurovera uye kukundikana. Dambudziko rinoongororwa zvakadzama uye matekiniki ekugadzirisa matanho akaongororwa. Izvozvi, chinongedzo chinotakura otomatiki kuzivikanwa tekinoroji uye ine simba torque feedforward tekinoroji, kudhumhana kwekutsvaga tekinoroji, zero poindi yekuvandudza tekinoroji, uye pakupedzisira ramangwana rekuvandudza maitiro emunhu-muchina kubatana pamwe neruzivo fusion zvinokurudzirwa. |

Nekufarirwa kweCCC maturusi emuchina, vazhinji uye vazhinji vashandisi vanotarisira kuti kurodha pasi uye kuburitsa kweCCC muchina maturusi anozoitwa otomatiki. Kune rimwe divi, ichawedzera huwandu hwevashandi kuti vatore michina maturusi, kudzikisa mutengo wevashandi, uye kugadzirisa kugadzirwa kwekuita uye mhando kune rumwe rutivi. Iko kushandiswa kukuru kwemabhoti emaindasitiri kwakatangira muindasitiri yemotokari. Nekuzadza kwemagetsi indasitiri kunyorera, iyo indasitiri yakawedzera kuziva marobhoti. Kubva kuma1990, marobhoti emumaindasitiri muminda yakajairwa akashandiswa zvakanyanya, sekushambadza, kukwizisa, kupopera, kurodha uye kuburutsa, kupora uye kukuya zvinoitwa zvakajairika mumaindasitiri akajairika. Ichi chinyorwa chinotarisa kurodha pasi uye kudzikisa system yeindasitiri robhoti machine.

Iyo maindasitiri robhoti machine kurodha uye kurodha pasi sisitimu inowanzo shandiswa kurodha kweanogadzira mayuniti uye otomatiki ekugadzira mitsara kuti aongororwe asina kukwana, kuburitsa zvinhu zvakagadziriswa workpieces, kuendesa kweanoshanda pakati pemashini maturusi uye maturusi maturusi kutendeuka, kugadzira uye kukuya. Otomatiki kugadzirisa kwesimbi yekucheka muchina maturusi akadai sekucheka uye kuchera.

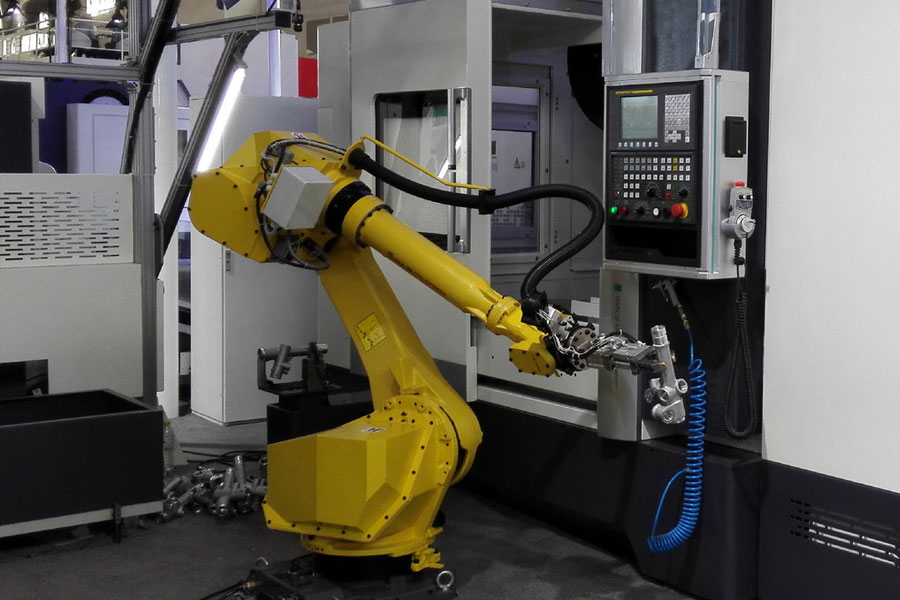

Iko kusunganidzwa kwepedyo kwemarobhoti uye maturusi emuchina haana kungogadziridza iwo mwero wekugadzira otomatiki, asi zvakare kwakavandudza kugona kwekugadzira uye kukwikwidza kwefekitori. Mechiniki kugadzirisa kurodha uye kuturura kunoda kudzokororwa uye kuenderera mashandiro, uye kunoda kuenderana uye kurongeka kwekushanda, nepo kugadzirisa maitiro ezvikamu mumafekitori akajairwa kunofanirwa kuenderera mberi kuchigadziriswa nemazhinji mashandisi maturu uye akawanda maitiro. Nekuwedzera kwemitengo yevashandi uye kumanikidza kwekumanikidza kunounzwa nekuwedzera mukugadzirwa kwekugadzirwa, iwo mwero wekushandisa kwekugadzirisa kugona uye kugona kugadzirisa kwekugadzira zvave zvipingaidzo mukuvandudzwa kwemakwikwi emuchina. Robhoti inotsiva mashandiro ekurodha uye kudzikisira mashandiro, uye inoona inoshanda otomatiki kurodha uye kurodha pasi sisitimu kuburikidza ne otomatiki ekudyisa mabhini, mabhandi ekufambisa, nezvimwe, sezvakaratidzwa muMufananidzo 1.

Imwe robhoti inogona kuenderana nekutakudza nekuburitsa mashandiro eimwe kana anopfuura maturu emuchina zvinoenderana nezvinodiwa zvehunyanzvi hwekugadzirisa. Mune robhoti imwe-kune-yakawanda kurodha uye kuburitsa system, iyo robhoti inopedzisa kunhonga uye kuisa zvisipo uye zvakagadziriswa zvikamu mune akasiyana muchina maturusi, izvo zvinonyatso kuvandudza mashandisiro ekushandisa kwerobhoti. Robhoti inogona kuita mashandiro ekudzosera pane yakatarwa dhizaini yemuchina chishandiso gungano tambo kuburikidza neyera yakaiswa pasi, iyo inoderedza kugarwa kwenzvimbo yefekitori, uye inogona kuchinjika kuchinjika kune akasiyana mashandiro maitiro emabatch akasiyana ezvigadzirwa. Robhoti inochinja inogona kuramba ichishanda munzvimbo dzakaomarara. , Kushanda kwemaawa makumi maviri nemasere, kusunungura zvakakwana kugona kwekugadzirwa kwefekitori, kupfupisa nguva yekuendesa, uye kugadzirisa kukwikwidza kwemusika.

1 Hunhu hwemaindasitiri marobhoti machining kurodha uye kudzikisa kunyorera

- (1) Yakakwira-chaiyo yekumisikidza kumisikidza, kubata nekukurumidza uye kuomerera, kupfupisa iyo kutenderera kutenderera, uye nekuvandudza kushanda kwemushini chishandiso.

- (2) Robhoti mashandiro akatsiga uye akavimbika, achinyatso kudzikamisa isina kukodzera zvigadzirwa uye nekuvandudza chigadzirwa mhando.

- (3) Kuenderera mberi kwekushanda pasina kuneta, kudzikamisa iyo idle mwero wemashini maturusi, uye kuwedzera fekitori yekugadzira kugona.

- (4) Iyo yakakwira mwero yekushandisa otomatiki inovandudza iwo iwo chaiwo ekugadzirwa kwechimwe chigadzirwa uye inomhanyisa iyo yakawanda yekugadzira kugadzirwa.

- (5) Yakanyanya kuchinjika, inokurumidza uye inoshanduka kuchinjika kumabasa matsva uye zvigadzirwa zvitsva, uye kupfupisa nguva yekuendesa.

2 Matambudziko mukushandiswa kweindasitiri robhoti machine uye kurodha pasi uye kudzikisa

2.1 Kuomarara uye kurongeka nyaya

Iyo machining robhoti yakasiyana neyakajairika kubata uye kubata marobhoti. Icho chiitiko chinobata zvakananga zvishandiso zvekugadzirisa. Yayo inofamba musimboti inofanirwa kufunga nezve kuomarara uye kurongeka. Iyo tandem robhoti ine yakakwira kudzokorora kumisikidza kurongeka, asi nekuda kweiyo yakazara zvinhu zvinhu zvekugadzirisa, gungano, kuomarara, nezvimwe, iyo trajectory kururamisa haina kukwirira, iyo ine simba rakakura pane zvinoshandiswa senge kukuya, kupukuta, deburring, uye kucheka mukati iyo machining munda. Naizvozvo, kuomarara kwerobhoti uye kunyatsoita marobhoti trajectory ndiwo matambudziko makuru anotarisana nemuchina we robhoti.

2.2 Dambudziko rekukonana

Mazhinji emarobhoti ekushandira anoshanda pamwe nekutendeuka, kugaya, kuronga, uye kukuya maturu emuchina. Kana iyo robhoti iri kuita machining, yakanyanya kutarisirwa inofanirwa kubhadharwa kune dambudziko rekupindira uye kurovera pakati penzvimbo yakafa uye neyaishandira. Kamwe kubonderana kukaitika, zvese zvishandiso zvemuchina uye iro robhoti zvinoda kuitwazve, izvo zvinowedzera zvakanyanya nguva yekukanganisa kupora, zvichikonzera kurasikirwa kwezvakabuda, uye muzviitiko zvakakomba, zvinogona zvakare kukonzera kukuvara kwemidziyo. Iko kuona kusati kwatanga kana mushure mekurovera ndiro dambudziko rakakura rinotarisana nekuchengetedza uye kugadzikana kwemarobhoti akagadzirwa. Izvo zvinonyanya kukosha kuti marobhoti ave nenzvimbo yekutarisa uye yekurovera kuona mabasa.

2.3 Kurumidza kupora dambudziko mushure mekundikana

Iyo chinzvimbo data re robhoti inodyiswa kumashure kuburikidza neiyo mota encoder yekutyaira mugodhi kufamba. Nekuda kwekushanda-kwenguva refu, iyo mechimiro chimiro, encoder bhatiri, tambo uye zvimwe zvinhu zvinongopedzisira zvaita kuti zero chinzvimbo (chirevo chinzvimbo) che robot irasikirwe. Mushure mekunge zero nzvimbo yarasika, robhoti rinozvichengeta. Iyo data data haizove nechinoshanda chirevo. Panguva ino, kana iyo zero nzvimbo isingakwanise kudzoreredzwa nenzira kwayo, iro robhoti basa rekudzosa basa rakakura, saka zero chinzvimbo chinzvimbo chekugadzirisa dambudziko rakanyanya kukosha.

3 Mhinduro dzakakosha

3.1 End mutoro otomatiki kuzivikanwa tekinoroji uye ine simba torque feedforward tekinoroji

Iyo otomatiki yekupedzisira mutoro yekuzivisa tekinoroji inogona kuona iyo saizi, pakati pehuremu uye inertia yemagumo mutoro we robhoti. Aya ma parameter anogona kushandiswa mu robot dynamics feedforward, kugadzirisa iyo servo parameter uye nekumhanyisa kuronga, iyo inogona kuvandudza zvakanyanya iyo irobhoti trajectory kunyatso uye kwakasimba kwesimba kuita.

Iyo ine simba torque feedforward tekinoroji inoenderana neyetsika PID kudzora uye inowedzera iyo torque feedforward yekudzivirira tekinoroji. Iri basa rinogona kushandisa iro robhothi dynamics modhi uye yekukwesana modhi kuti uverenge yakaringana simba rekutyaira kana torque paunenge uchironga iyo trajectory nzira zvinoenderana neiyo static ruzivo senge iyo robhoti uye chaiyo-nguva ine simba ruzivo senge kumhanyisa uye kumhanyisa, uye iyo yakaverengerwa kukosha inoparadzirwa sekukosha kwekusimudzira. Ipai mutongi kuti aenzanise neakatemwa kukosha kwemota mune chiuno chazvino, kuti uwane torque yakanakisa, fambisa kumhanya-kumhanya uye kwakanyanya-kunyatso fambisa kune yega yega axis, uyezve woita kuti kumagumo TCP iwane yepamusoro trajectory kurongeka.

3.2 Kugona kuona tekinoroji

Iyi tekinoroji yakavakirwa pamarobhothi dynamics modelling. Kana iro robhoti kana mutoro wekupedzisira werobhoti ukabonderana nemidziyo yekunze, iro robhoti rinokwanisa kuona iyo torque inogadzirwa nekurovera. Panguva ino, iro robhoti rinomira roga kana kuti rinoenda kwakapesana nekwakarovera nekumhanya kwakaderera. Mhanya kunzvenga kana kudzikisa kurasikirwa kunokonzerwa nekurovera.

3.3 Zero poindi yekudzosa tekinoroji

Dzakajairika zero-poindi calibration nzira, mushure mekurongedzwa kwe zero-mucherechedzo, kucharamba paine zvimwe zvikanganiso. Saizi yekukanganisa inoenderana neyakagadziriswa mhando yeiyo zero-mucherechedzo uye maitiro eanoshanda, uye chikamu ichi chekanganiso hachigone kubviswa nekuvandudza izvo zvinodiwa kugadzirisa uye kuita oparesheni yekudzidzira. . Ichishandisa tekinoroji iyi, robhoti parinorasikirwa nezero, robhoti rinoendeswa padhuze nepazero poindi, kuti mabara kana mitsara yemunyori inyatsoenderana. Panguva ino, verenga iyo encoder kukosha kuti uone muripo, kuitira kuti robhoti inyatso dzorera zero nzvimbo.

4 Nhungamiro yekusimudzira remangwana

4.1 Kubatana kwevanhu-muchina

Parizvino, mazhinji ekushandisa emarobhoti emabhizimusi ari munzvimbo dzekushandira kana mitsara yegungano, uye hapana kubatana uye kubatana nevanhu. Mune ramangwana, kubatana pakati pevanhu nemarobhoti ichave yakakosha nzira yekuvandudza kune akaomesesa maitiro ekugadzira. Nyaya dzakakosha idzo marobhoti emaindasitiri anoda kugadzirisa kuti vabatsire vanhu-muchina mashandisiro maitiro ekuona mashandiro anoita vanhu, mashandiro aungaita nevanhu, uye chinhu chakakosha ndechekuti nzira yekuchengetedza nzira yekuchengetedzeka kwevanhu- muchina kubatana. Ndichiri kuziva kubatana kwemuchina-wevanhu uye kuona kuchengeteka kwevanhu, zvinodawo kuti unyatso kufunga nezve rhythm yekugadzira, inova yakakosha maitiro. Mumakore achangopfuura, mamwe marobhoti anoshanda-muchina akabatana akaonekwa, asi pasi pemamiriro ekuona kuchengetedza, kurova kunononoka, uye kudzikama kunoda kugadziriswa. Zvinotonyanya kukosha, iri kukurumidza kusanganisa pamwe nezviitiko zvekushandisa uye nekuwana akakodzera mamiriro ekushandisa. Kuvandudza kwenyika nekusimudzira.

4.2 Ruzivo Fusion

Mune ramangwana, mafekitori akangwara anozobatanidza iyo Internet yezvinhu, sensors, marobhoti, uye data hombe. Maindasitiri marobhoti, seimwe yemidziyo yakakosha kwazvo, haifanire kungobatana chete nema sensors mazhinji, asi zvakare kutaurirana neepamusoro-masystem masisitimu seMES. Iyo sisitimu inoitisa ruzivo rwekuchinjana. Zvichienderana neInternet yezvinhu uye hombe dhata, iyo yepamusoro nhanho inoita dhizaini dhizaini, kugadzirisa chirongwa chirongwa, kana kure kure kuongororwa uye kugadzirisa kwemidziyo, uye inopa mirayiridzo kumarobhoti emaindasitiri kupedzisa iyo yese njere yekudzora maitiro. Naizvozvo, iyo fusion yeruzivo rwemaindasitiri marobhoti ichave yakakosha zvakanyanya kusimudzira maitiro.

Batanidza kuchinyorwa ichi: Iko Kushanda Kweindasitiri Robhoti Mashini Kuisa Uye Kuburutsa

Dzokorora Chirevo: Kana pasina mirairo yakakosha, zvinyorwa zvese zviri pasaiti ino ndezvepakutanga. Ndokumbira uratidze kwakabva kudhindazve: https://www.cncmachiningptj.com/, thanks!

PTJ CNC shopu inogadzira zvikamu zvine yakanakisa michina zvivakwa, kurongeka uye kudzokorora kubva kusimbi nepurasitiki. 5 akabatana CNC azvikuya iripo.Kugadzira yakakwira-tembiricha chiwanikwa range inclouding inconel machine,monel machine,Kugadziriswa kweGeek Ascology,Carp 49 machine,Hastelloy machine,Nitronic-60 machine,Hymu 80 kugadzira,Danho Simbi machine, nezvimwe.,. Yakanakira kunyorera nzvimbo.CNC machining inogadzira zvikamu zvine yakanakisa mehendi zvivakwa, kurongeka uye kudzokorora kubva pasimbi nepurasitiki. 3-axis & 5-axis CNC yekugaya iripo.Ticharonga pamwe newe kuti tipe yakanyanya-isingadhuri masevhisi ekukubatsira iwe kuti usvike kune chako chinangwa, Gamuchirai Kwatiri isu ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

PTJ CNC shopu inogadzira zvikamu zvine yakanakisa michina zvivakwa, kurongeka uye kudzokorora kubva kusimbi nepurasitiki. 5 akabatana CNC azvikuya iripo.Kugadzira yakakwira-tembiricha chiwanikwa range inclouding inconel machine,monel machine,Kugadziriswa kweGeek Ascology,Carp 49 machine,Hastelloy machine,Nitronic-60 machine,Hymu 80 kugadzira,Danho Simbi machine, nezvimwe.,. Yakanakira kunyorera nzvimbo.CNC machining inogadzira zvikamu zvine yakanakisa mehendi zvivakwa, kurongeka uye kudzokorora kubva pasimbi nepurasitiki. 3-axis & 5-axis CNC yekugaya iripo.Ticharonga pamwe newe kuti tipe yakanyanya-isingadhuri masevhisi ekukubatsira iwe kuti usvike kune chako chinangwa, Gamuchirai Kwatiri isu ( sales@pintejin.com ) zvakananga purojekiti yako nyowani.

- 5 Sekaiichi machine

- Cnc Kugaya

- Cnc Kutendeuka

- Machining Maindasitiri

- Machining Maitiro

- Surface Kurapa

- Simbi yekushandisa

- Mapepa epurasitiki

- Upfu hweMetallurgy Mould

- Die Casting

- Zvikamu Garari

- Auto Metal Zvikamu

- Machinery Parts

- Akatungamira Heatsink

- Kuvaka Zvikamu

- Sravana Sameeralu Serial XNUMXth Mobile Parts

- Zvikamu Zvekurapa

- Zvikamu Zvemagetsi

- Zvichienderana machine

- Bicycle Parts

- Aluminum machine

- Titanium Kubata

- Stainless Simbi machine

- Mhangura machine

- Brass machine

- Super chiwanikwa machine

- Peek Kugadzira

- UHMW machine

- Sanganisa Machining

- PA6 Kugadzira

- PPS machine

- Teflon Kugadzira

- Inconel machine

- Danho Simbi machine

- Zvimwe Zvinyorwa